Sharp MX-M700 MX-M550 MX-M620 MX-M700 Operation Manual - Page 77

Troubleshooting finisher/saddle stitch finisher problems

|

View all Sharp MX-M700 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 77 highlights

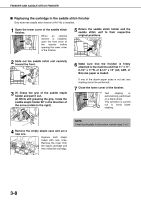

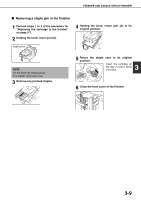

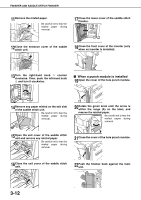

FINISHER AND SADDLE STITCH FINISHER Troubleshooting finisher/saddle stitch finisher problems Check the list below before calling for service. Problem Check Solution or cause Stapling position is not correct (including saddle stitch). Stapling position not set properly? Check the stapling position setting. (See page 3-4.) The finisher/saddle stitch finisher does not operate. Are any finisher/saddle stitch finisher covers open? Message indicating need to remove paper from the stapler compiler displayed? Close all covers. (See step 7 on page 3-7 and step 7 on page 3-11.) Remove all remaining paper from the stapler compiler. (For the stapler compiler, see "Part names" on page 3-2.) Message to check the staple unit Remove jammed staples. (See pages 3-9 and displayed? 3-10.) Message to add staples displayed? 3 Replace the staple cartridge. (See pages 3-7 and 3-8.) Check that a staple cartridge has Stapling cannot be been installed. (See pages 3-7 and 3-8.) performed (including saddle stitch). Different sizes of paper mixed together? Stapling cannot be performed on mixed paper sizes. The paper is badly curled. The quality and type of some papers may cause bad curling that prevents stapling. Take the paper out of the tray or bypass tray, turn the stack over, and reload it. Saddle stitch cannot be selected. The paper type of the selected paper tray is set to heavy paper. Saddle stitch is not possible on heavy paper. However, when cover insertion is selected, saddle stitch is possible on a single sheet of heavy paper inserted for use as a cover. The punch hole positions are not correct.* The punch function is not set to the correct punch positions. Check the allowed hole punch positions. (See page 3-5.) Message to check the punch module displayed? Dispose of punch scraps. (See page 3-10.) Mixed paper sizes. Cannot be punched.* The paper is badly curled. Punching is not possible when different paper sizes are mixed together. The quality and type of some papers may cause bad curling that prevents punching. Take the paper out of the tray or bypass tray, turn the stack over, and reload it. * When a hole punch module is installed 3-13