Troy-Bilt Pony Operation Manual - Page 21

Maintenance Schedule, Seat Adjustment, Parking Brake Adjustment - oil change

|

View all Troy-Bilt Pony manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 21 highlights

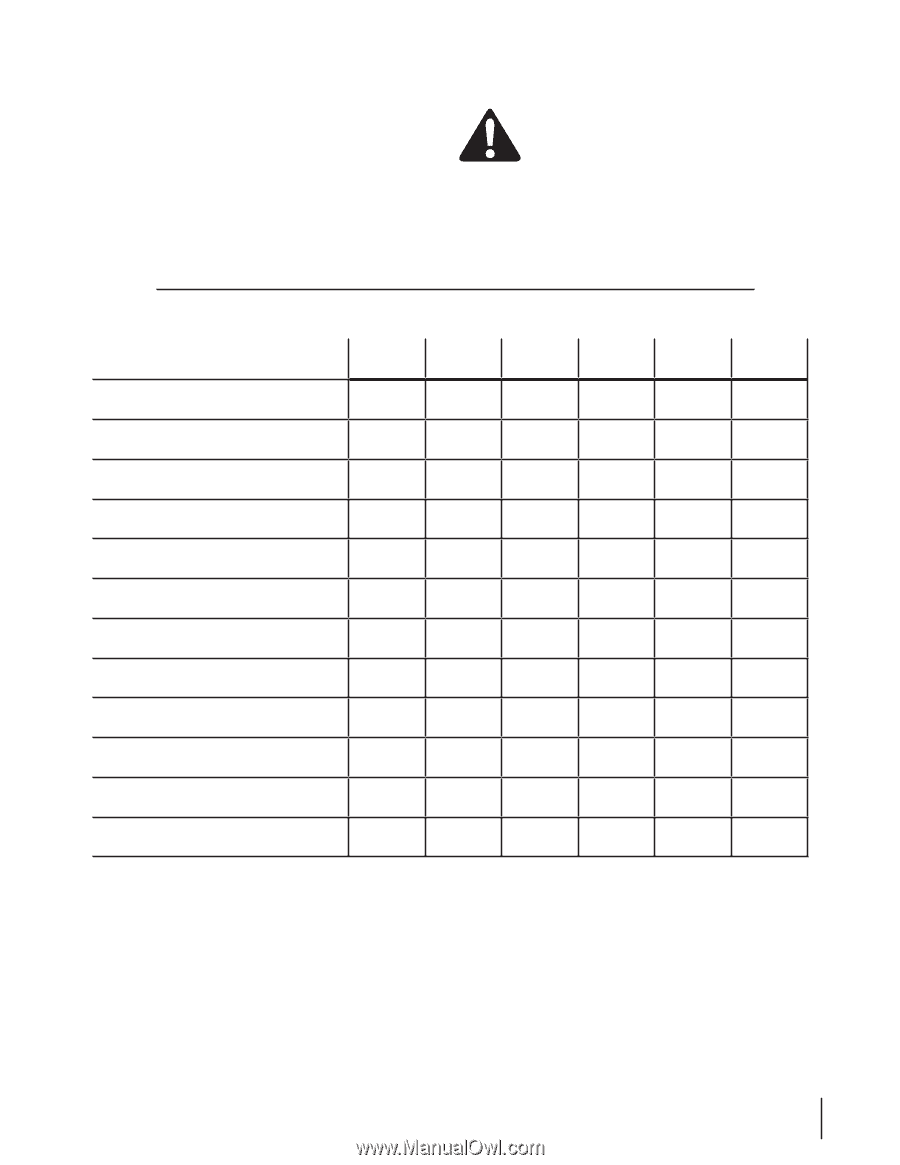

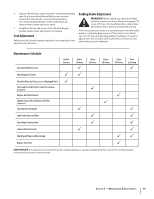

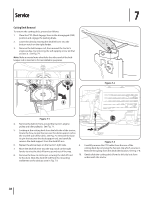

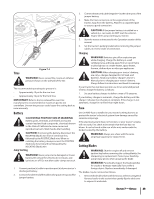

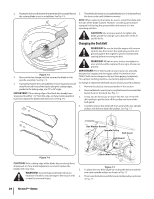

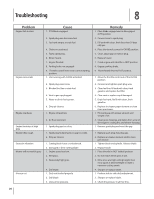

4. Balance the deck by using a wrench to turn the adjustment gear (found immediately behind the hex cap screw just loosened) clockwise/up or counterclockwise/down. The deck is properly balanced when both blade tip measurements taken earlier are equal. 5. Retighten the hex cap screw on the left deck hanger bracket when proper adjustment is achieved. Seat Adjustment Refer to the Set-Up and Assembly section of this manual for seat adjustment instructions. Parking Brake Adjustment WARNING: Never attempt to adjust the brakes while the engine is running. Always disengage PTO, move shift lever into neutral position, stop engine and remove key to prevent unintended starting. If the tractor does not come to a complete stop when the brake pedal is completely depressed, or if the tractor's rear wheels can roll with the parking brake applied, the brake is in need of adjustment. See an authorized Troybilt Service Dealer to have your brakes properly adjusted. Maintenance Schedule Clean Hood/Dash Louvers Check Engine Oil Level Before Each use P Every 10 Hours P P Every 25 Hours Every 50 Hours Every 100 Hours Prior to Storing P Check Air Filter for Dirty, Loose or Damaged Parts P Clean and Re-oil Air Filter's Foam Pre-cleaner (if Equipped) P Replace Air Filter Element Change Engine Oil and Replace Oil Filter (if Equipped) P P Clean Battery Terminals P P Lube Front Axles and Rims P P Clean Engine Cooling Fins Lube Pedal Pivot Points P P P P Check Spark Plug Condition & Gap Replace Fuel Filter PP P IMPORTANT: It is important to consult the specific engine operator's manual included with this machine for detailed engine maintenance procedures and intervals. Section 6 - Maintenance & Adjustments 19