Troy-Bilt Pro-Line CRT Operation Manual - Page 8

Move Tiller Off Crate - tillers

|

View all Troy-Bilt Pro-Line CRT manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 8 highlights

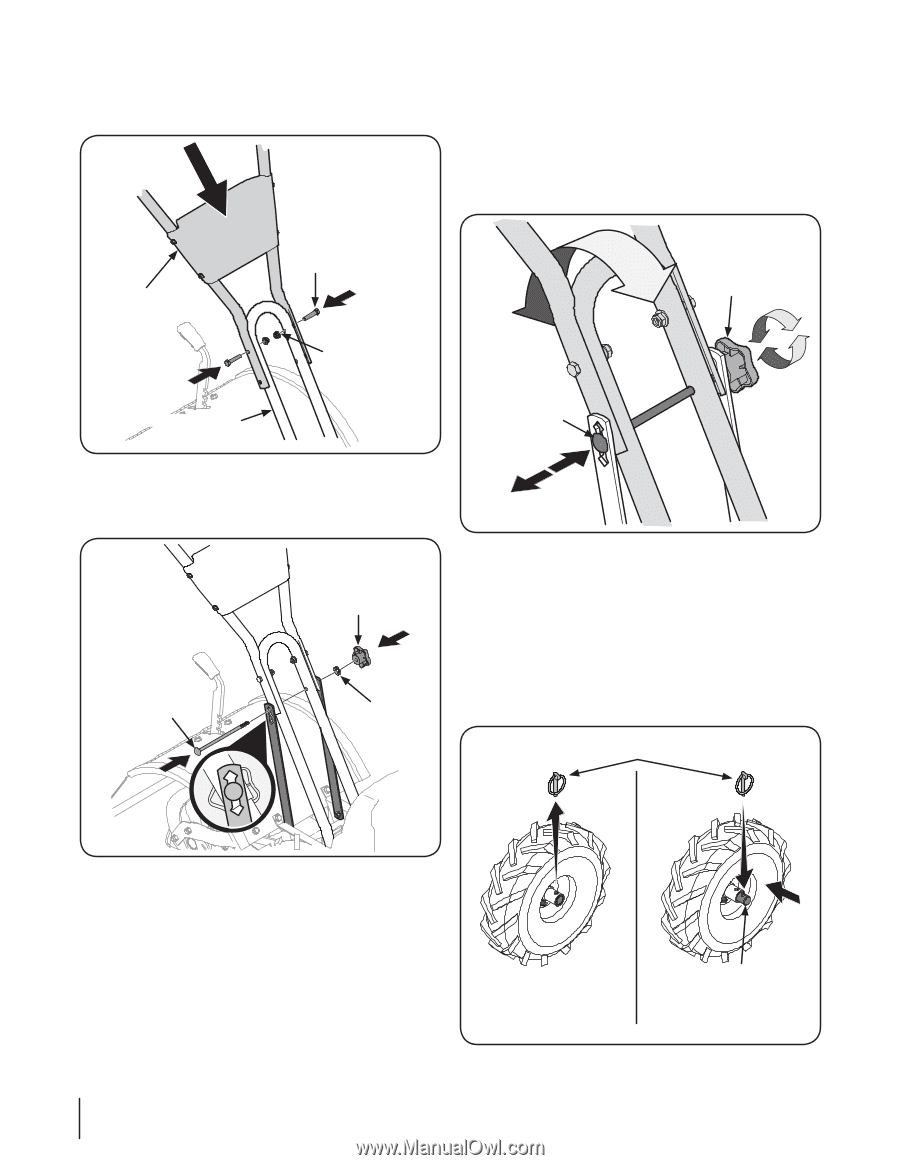

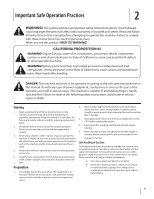

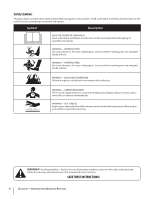

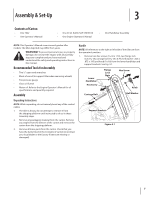

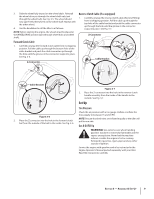

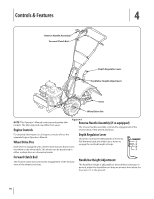

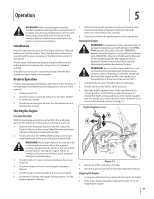

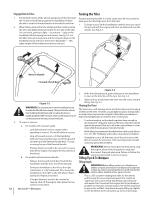

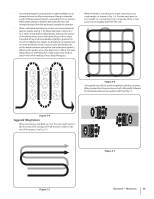

2. Using two hex screws and two flange lock nuts, loosely attach the handlebar support using the upper holes. Tighten the two screws securely. See Fig. 3-2. 4. There are three height adjustment holes in the handlebar support bracket. Use a setting that will position the handlebars at approximately waist level when the tines are 3-4" into the soil. To adjust the height of the handlebars loosen the knob on the handle, pull out on the carriage screw, adjust to the desired setting, push the carriage screw in until the square portion of the screw locks into place and re-tighten the knob. See Fig. 3-4. Upper Handle Hex Screw Flange Lock Nut Knob Handle Support Carriage Screw Figure 3-2 3. Loosely attach the support brackets to the outside of the handlebar assembly using the carriage bolt, bell washer and knob. Refer to Fig. 3-3. Knob Carriage Bolt Bell Washer Figure 3-4 4. Tighten all the handlebar mounting hardware securely. Move Tiller Off Crate To roll the tiller off the shipping platform, put the wheels in freewheel, as follows: 1. Place a sturdy block under the transmission to raise one wheel about 1" off the ground. 2. Remove the wheel drive pin from the wheel hub and wheel shaft. See Fig. 3-5. Wheel Drive Pin Figure 3-3 NOTE: If a support bracket will not move, loosen the attaching hex screws (5⁄16-18 x .75) and flange lock nuts (5⁄1618) at the base of the support brackets. NOTE: The support brackets must be assembled to the outside of the handlebar assembly. 8 Section 3- Assembly & Set-Up Wheel Shaft Figure 3-5