Troy-Bilt TB554 Operation Manual - Page 11

Edging Along a Curb, Beveling, Trenching If equipped - belt

|

View all Troy-Bilt TB554 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 11 highlights

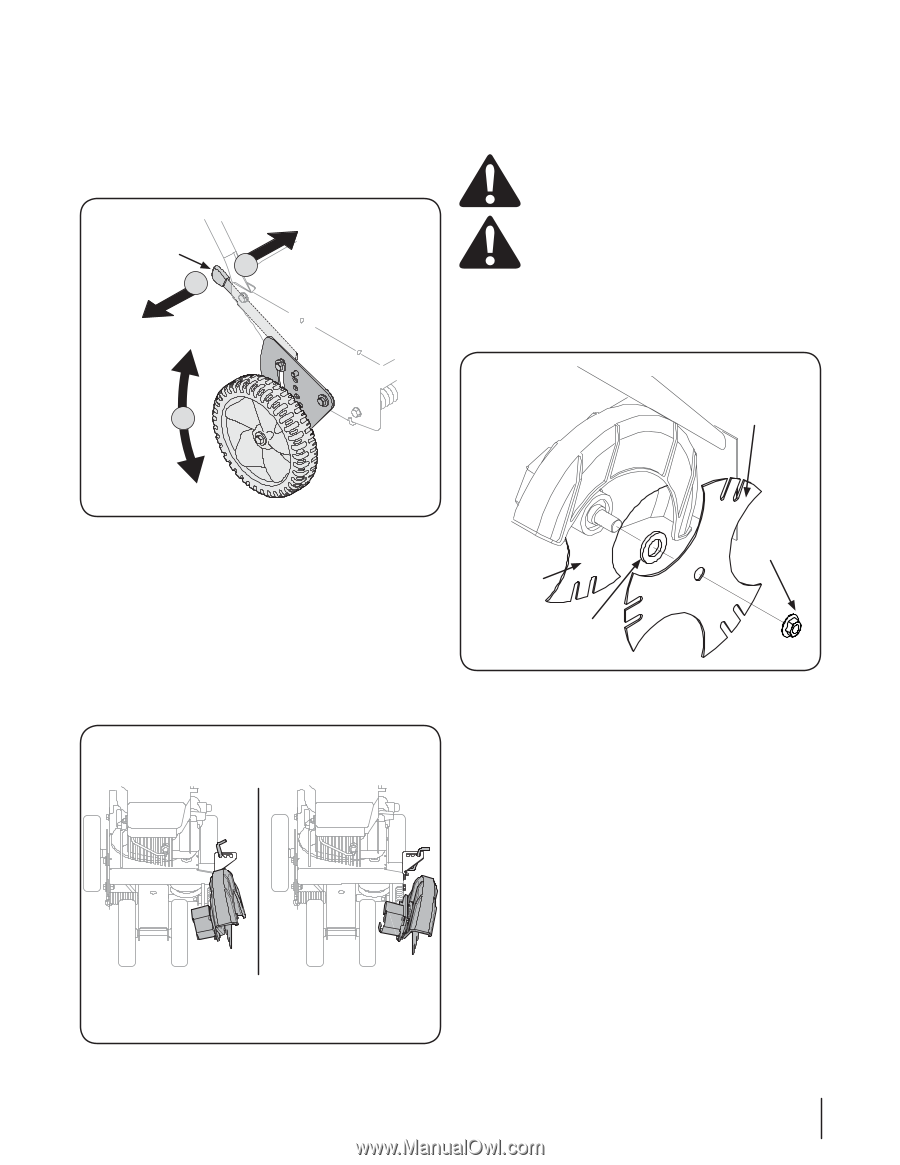

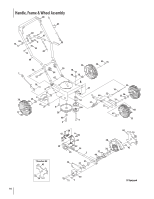

Edging Along a Curb The right, rear wheel of the edger can be lowered into one of five positions to ease the task of edging along a curb. To adjust the height of curb wheel, proceed as follows: 1. Lower the right, rear wheel by moving the curb height adjustment lever slightly to the left. See Figure 5-3. Curb Height Adjustment Lever 1 3 Trenching (If equipped) You can utilize the edger's optional trenching feature in order to create a wider cutting path for such things as laying wire for landscape lighting. WARNING! Disconnect the spark plug wire and ground against the engine before performing the following steps. WARNING! The edger blade is sharp. Wear leather work gloves to protect your hands when working around the edger blade. 1. Use two wrenches (one wrench to prevent the hex bolt head from spinning and the other to unthread the flange nut) to remove the flange nut that secures the edger blade, leaving the edger blade in place. See Figure 5-5. 2 Tri-Star Blade Figure 5-3 2. Pivot the right, rear wheel into an applicable position in relation to the height of the curb to be edged along. 3. Release the curb height adjustment lever to lock the wheel in position. See Figure 5-3. Beveling In order to achieve a bevelled edge, set the bevel adjustment lever (refer to the Assembly & Set-Up Section) in the first (left hand) or third (right hand) notch to place the edger blade in position for beveling. See Figure 5-4. Edger Blade Flat Washer Flange Nut Figure 5-5 2. Install the additional edger blade supplied with your machine and the flat washer. See Figure 5-5. 3. Secure with the flange nut removed earlier. Use a torque wrench to tighten the flange nut to between 37 foot-lbs. and 50 foot-lbs. NOTE: Make certain that the drive belt is seated correctly on the blade spindle and that it is riding smoothly on the spindle sheaves and is not pinched between them. Repeat the first three steps if belt is pinched. Right-Hand Position Left-Hand Position Figure 5-4 Section 5 - Operation 11