Troy-Bilt TB554 Operation Manual - Page 12

Maintenance & Adjustments - edger belt installation

|

View all Troy-Bilt TB554 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 12 highlights

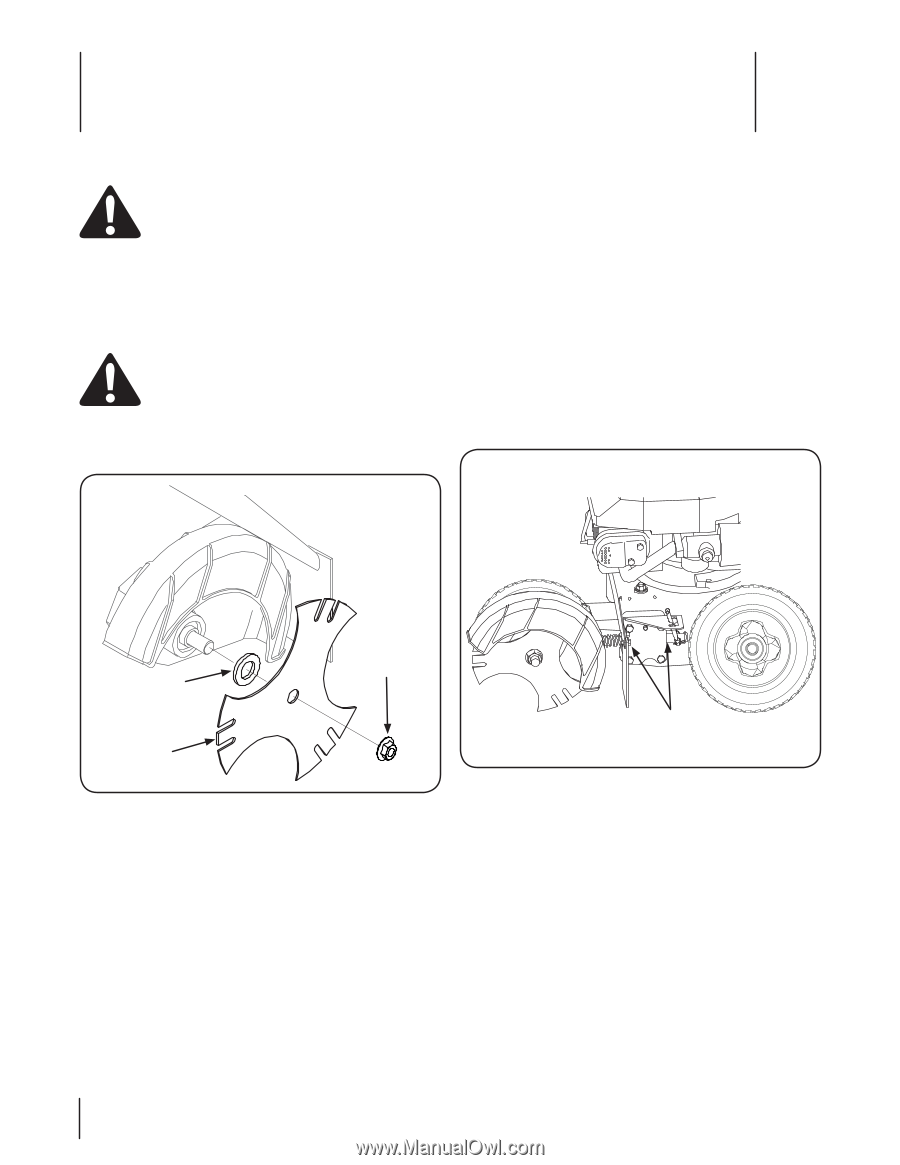

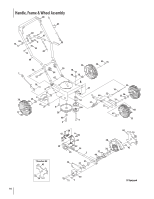

Maintenance & Adjustments 6 Maintenance WARNING! Disconnect the spark plug wire and ground against the engine before performing any adjustment, repairs or maintenance. Engine Refer to the Engine Operator's Manual packed with your edger for a detailed description of all engine-related service specifications. Edger Blade WARNING! The edger blade is sharp. Wear leather work gloves to protect your hands when working around the edger blade. 1. Use two wrenches (one wrench to prevent the hex bolt head from spinning and the other to remove the flange nut) to remove the edger blade. Refer to Figure 6-1. Lubrication Wheels Lubricate the wheels and bearings at least once a season with a light oil. Also if the wheels are removed for any reason, lubricate the surface of the axle bolt and the inner surface of the wheel with light oil. Pivot Points Lubricate the pivot points on the blade control bail, blade depth control lever, and if applicable, the blade adjustment lever, and curb height adjustment lever with light oil at least once a season. Bearing Block Lubricate the bearing block every 25 hours or at least once a season. Simply apply oil at each end of the cover plate. See Figure 6-2. Flat Washer Flange Nut Edger Blade Figure 6-1 2. Remove and discard the edger blade but retain the flange nut. 3. Install the replacement edger blade and the flange nut removed earlier. Use a torque wrench to tighten the flange nut to between 37 foot-lbs. and 50 foot-lbs. NOTE: Make certain that the drive belt is seated correctly on the blade spindle and that it is riding smoothly on the spindle sheaves and is not pinched between them. Repeat the first three steps if the belt is pinched. 12 Lubricate Figure 6-2