Beretta 92 FS Compact Inox Operating Instructions - Page 14

Recommended, Safety, Feature, Inspection, Cleaning, Barrel, Cleaning, Lubrication, Slide

|

View all Beretta 92 FS Compact Inox manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 14 highlights

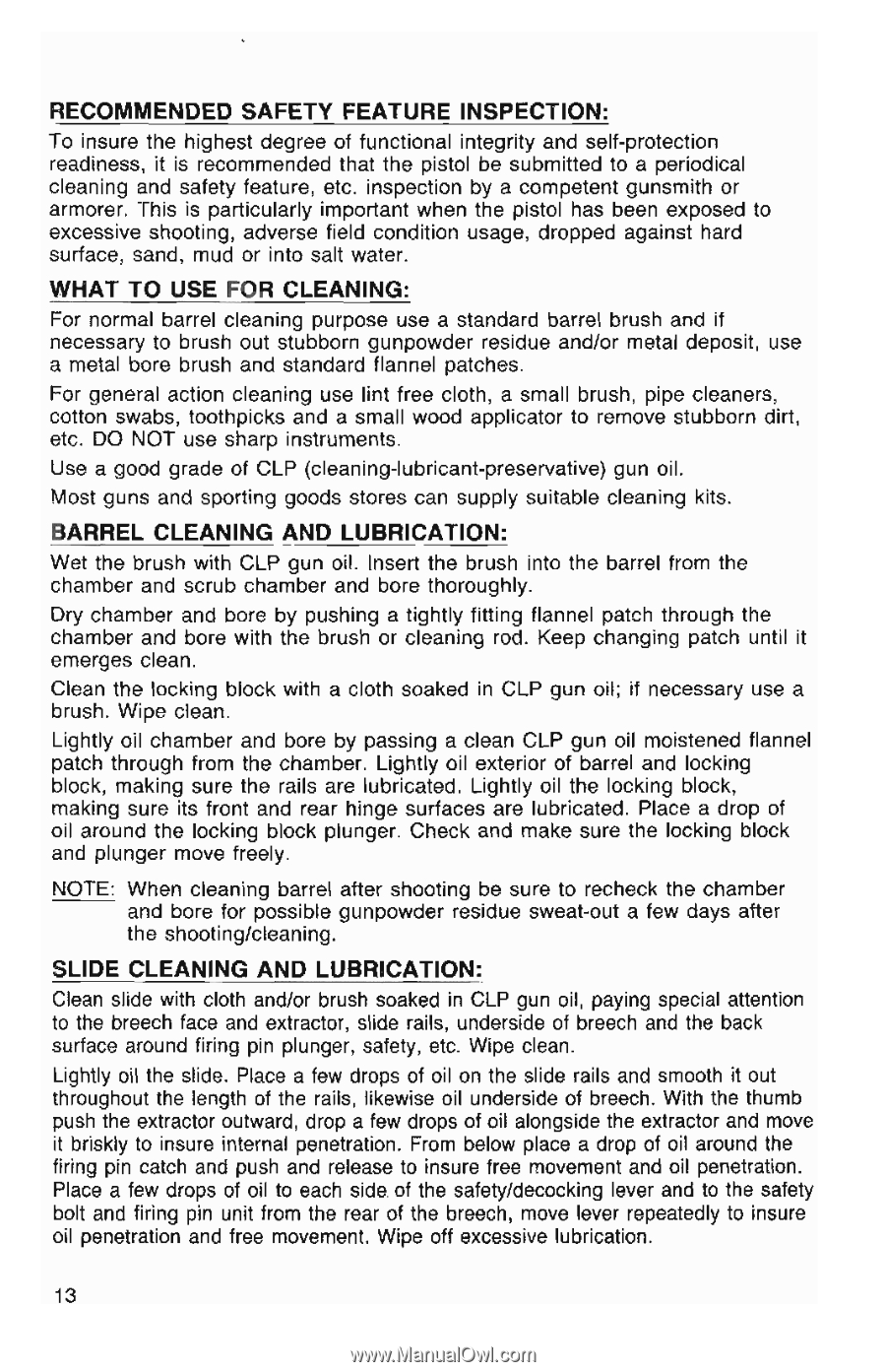

RECOMMENDED SAFETY FEATURE INSPECTION: To insure the highest degree of functional integrity and self-protection readiness, it is recommended that the pistol be submitted to a periodical cleaning and safety feature, etc. inspection by a competent gunsmith or armorer. This is particularly important when the pistol has been exposed to excessive shooting, adverse field condition usage, dropped against hard surface, sand, mud or into salt water. WHAT TO USE FOR CLEANING: For normal barrel cleaning purpose use a standard barrel brush and if necessary to brush out stubborn gunpowder residue and/or metal deposit, use a metal bore brush and standard flannel patches. For general action cleaning use lint free cloth, a small brush, pipe cleaners, cotton swabs, toothpicks and a small wood applicator to remove stubborn dirt, etc. DO NOT use sharp instruments. Use a good grade of CLP (cleaning-lubricant-preservative) gun oil. Most guns and sporting goods stores can supply suitable cleaning kits. BARREL CLEANING AND LUBRICATION: Wet the brush with CLP gun oil. Insert the brush into the barrel from the chamber and scrub chamber and bore thoroughly. Dry chamber and bore by pushing a tightly fitting flannel patch through the chamber and bore with the brush or cleaning rod. Keep changing patch until it emerges clean. Clean the locking block with a cloth soaked in CLP gun oil; if necessary use a brush. Wipe clean. Lightly oil chamber and bore by passing a clean CLP gun oil moistened flannel patch through from the chamber. Lightly oil exterior of barrel and locking block, making sure the rails are lubricated. Lightly oil the locking block, making sure its front and rear hinge surfaces are lubricated. Place a drop of oil around the locking block plunger. Check and make sure the locking block and plunger move freely. NOTE: When cleaning barrel after shooting be sure to recheck the chamber and bore for possible gunpowder residue sweat-out a few days after the shooting/cleaning. SLIDE CLEANING AND LUBRICATION: Clean slide with cloth and/or brush soaked in CLP gun oil, paying special attention to the breech face and extractor, slide rails, underside of breech and the back surface around firing pin plunger, safety, etc. Wipe clean. Lightly oil the slide. Place a few drops of oil on the slide rails and smooth it out throughout the length of the rails, likewise oil underside of breech. With the thumb push the extractor outward, drop a few drops of oil alongside the extractor and move it briskly to insure internal penetration. From below place a drop of oil around the firing pin catch and push and release to insure free movement and oil penetration. Place a few drops of oil to each side. of the safety/decocking lever and to the safety bolt and firing pin unit from the rear of the breech, move lever repeatedly to insure oil penetration and free movement. Wipe off excessive lubrication. 13