Beretta 92 FS Compact Inox Operating Instructions - Page 6

sear/hammer

|

View all Beretta 92 FS Compact Inox manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 6 highlights

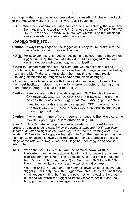

2. Firing Pin Unit: The two piece firing pin unit functioning on the inertia principle is designed to insure positive discharge combined with ultimate accidental discharge prevention during slide reciprocation chamber loading, hammer decocking and/or inadvertent handling impact. Since the firing pin unit is shorter than the slide breech, the pistol can be safely carried with the chamber loaded and the hammer fully-lowered to rest against the breach. During hammer lowering by the safetydecocking lever, the rear section of the firing pin is rotated out of hammer reach. (Fig. 1-D2) 3. Hammer Drop Catch (half-cocked): Since this is a double action pistol this device is intended as a safety OFF, emergency, accidental discharge preventive hammer drop catch. To counteract the remote chance of accidental discharge due to UNTRIGGERED sear/hammer notch disengagement from the fully-cocked position, failure of hammer cocking during slide recoil reciprocation, inadvertent hammer fanning or thumb slipping off the hammer spur during cocking, the hammer is caught half-cocked by the sear before striking the firing pin unit. To protect this device against hammer spur impact damage DO NOT carry the hammer half-cocked but fully-lowered. 4. Automatic Firing Pin Catch: This device positively prevents accidental discharge of a chambered round by firing pin inertia should the pistol inadvertently be dropped onto the ground. Also, it prevents firing pin inertia (primer ding mark) discharge of a cartridge during manual slide manipulation chamber loading as well as automatic slide recoil reciprocating chambering during shooting while the shooter keeps the trigger retracted. This device only becomes disconnected to permit pistol discharge at the last stage of either the double or single action trigger pull. Further, by being clearly visible in front of the rear sight the shooter can at a glance verify if the catch is engaged DOWN or disengaged UP. (Fig. 1-D2 and Fig. 3-D2) 5. Chamber Loaded Indicator: When a cartridge is chambered, the extractor head protrudes outide the slide breech, exposing a red warning signal. In the dark, the protrusion can be felt by touch. This makes it unnecessary to pull back the slide to verify if the chamber is loaded. (Fig. 4-D3) 6. Slide Overtravel Stop: The head flange of the hammer pin enters a matching travel groove cut into the underside of the left slide rail to stop the slide breech in case of recoil overtravel. (Fig. 1-D5) E. FIELD STRIPPING SIMPLICITY: Advanced disassembly latch design allows for quick and simple field stripping, even by a fatigued user under hostile conditions. (Fig.-1-E1) 5