Dewalt DCS372B Instruction Manual - Page 17

Restarting A Cut With The Blade Teeth Jammed

|

View all Dewalt DCS372B manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 17 highlights

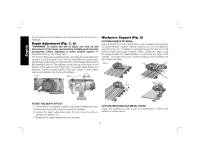

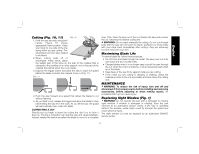

English Only operate saw when proper saw blade guard is in place. Mount blade securely in proper rotation before using, and always use a clean, sharp blade. Blade Diameter Teeth Application DWA7770 5-1/2" (140 mm) 30 General purpose ferrous metal cutting If you need assistance regarding blades, please call 1-800-4-DEWALT (1-800-433-9258). KICKBACK Kickback is a sudden reaction to a pinched, bound or misaligned saw blade, causing an uncontrolled saw to lift up and out of the workpiece toward the operator. When the blade is pinched or bound tightly by the kerf closing down, the blade stalls and the motor reaction drives the unit rapidly back toward the operator. If the blade becomes twisted or misaligned in the cut, the teeth at the back edge of the blade can dig into the top surface of the material causing the blade to climb out of the kerf and jump back toward the operator. Kickback is more likely to occur when any of the following conditions exists. 1. IMPROPER WORKPIECE SUPPORT A. Sagging or improper lifting of the cut off piece can cause pinching of the blade and lead to kickback (Fig. 9). B. Cutting through material supported at the outer ends only can cause kickback. As the material weakens it sags, closing down the kerf and pinching the blade (Fig. 9). C. Cutting off a cantilevered or overhanging piece of material from the bottom up in a vertical direction can cause kickback. The falling cut off piece can pinch the blade. D. Cutting off long narrow strips can cause kickback. The cut off strip can sag or twist closing the kerf and pinching the blade. E. Snagging the lower guard on a surface below the material being cut momentarily reduces operator control. The saw can lift partially out of the cut increasing the chance of blade twist. 2. IMPROPER DEPTH OF CUT SETTING ON SAW To make the most efficient cut, the blade should protrude only far enough to expose a tooth as shown in Figure 8. This allows the shoe to support the blade and minimizes twisting and pinching in the material. See the section titled Cutting Depth Adjustment. 3. BLADE TWISTING (MISALIGNMENT IN CUT) A. Pushing harder to cut can cause the blade to twist. B. Trying to turn the saw in the cut (trying to get back on the marked line) can cause blade twist. C. Overreaching or operating the saw with poor body control (out of balance), can result in twisting the blade. D. Changing hand grip or body position while cutting can result in blade twist. E. Backing up the saw to clear blade can lead to twist. 4. USE OF DULL OR DIRTY BLADES Dull blades cause increased loading of the saw. To compensate, an operator will usually push harder which further loads the unit and promotes twisting of the blade in the kerf. Worn blades may also have insufficient body clearance which increases the chance of binding and increased loading. 5. RESTARTING A CUT WITH THE BLADE TEETH JAMMED AGAINST THE MATERIAL The saw should be brought up to full operating speed before starting a cut or restarting a cut after the unit has been stopped with the blade in the kerf. Failure to do so can cause stalling and kickback. Any other conditions which could result in pinching, binding, twisting, or misalignment of the blade could cause kickback. Refer to the sections Further Safety Instructions for All Saws and Blades 15