Haier HB4800VA1M25 User Manual - Page 12

Orifice Change, Circulating Air Duct - manual

|

View all Haier HB4800VA1M25 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 12 highlights

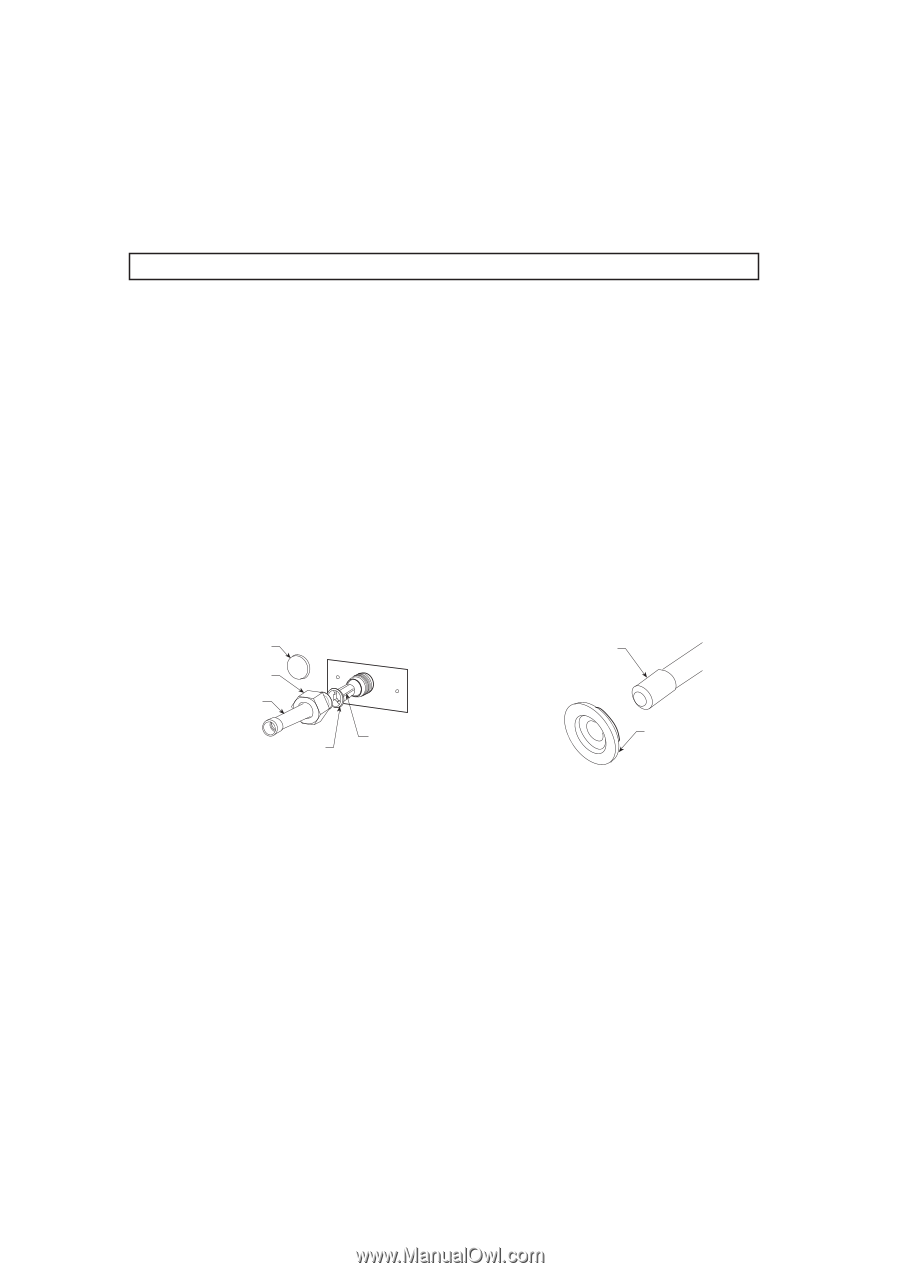

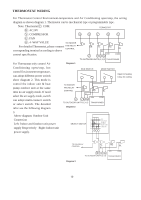

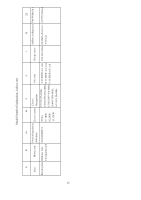

ORIFICE CHANGE The restrictor (orifice) included in this unit match the comparable capacity of the outdoor unit. If the indoor unit is greater in capacity than the outdoor condenser, the orifice must be changed to match the outdoor unit capacity. The restrictor (orifice) should be replaced before any tubing connections are made. THE CAPACITY OF THE OUTDOOR UNIT SHOULD NEVER EXCEED THE CAPACITY OF THE INDOOR UNIT. To replace the restrictor (orifice), follow the steps below: WARNING THIS COIL IS SHIPPED UNDER PRESSURE. FOLLOW THESE INSTRUCTIONS TO PREVENT INJURY: 1) Loosen the 13/16 nut 1TURN ONLY. No pressure loss indicates possible leak. 2) Remove the nut and discard the seal cap. 3) Remove the check piston to verify it is correct. See piston kit chart in instructions. 4) Use a tube cutter to remove the spin closure on the suction line. 5) Remove the tailpiece clamped to the exterior. 6) Slide the 13/16 nut into position. Braze tailpiece to the liquid tube. 7) Insert the suction line into the connection, slide the insulation and the rubber grommet at least 18" away from the braze joint. 8) AFTER THE TAILPIECE HAS COOLED, position the white Teflon seal and hand tighten the nut. 9) Torque the 13/16 nut to 10-30 ft/lbs. or tighten 1/6 turn. 10) Replace suction line grommet and insulation. SEAL CAP SUCTION LINE WITH SPIN 13/16 NUT CLOSURE TAIL PIECE WHITE TEFLON SEAL PISTON CIRCULATING AIR DUCT RUBBER GROMMET Air duct systems should be designed and installed as per local and/or national code.Refer to NFPA 90A & 90B and the National Environmental Systems Contractors Association Manual "K". The use of flexible duct connectors is recommended to minimize the possibility of noise transmission. These connectors must conform to U.L. standards. Supply air ducts must be insulated and return ducts must be insulated when passing through an unconditioned space. When passing through an unconditoned space it may be necessary to install a vapor barrier to the exterior of the ducts to prevent condensation. Seams of all supply ducts must be sealed to prevent leakage and return ducts sealed airtight to prevent infiltration. The supply plenum should be the dimensions specified by the factory. 12