Hayward HCP Pump HCP Series LITCPOMA10

Hayward HCP Pump Manual

|

View all Hayward HCP Pump manuals

Add to My Manuals

Save this manual to your list of manuals |

Hayward HCP Pump manual content summary:

- Hayward HCP Pump | HCP Series LITCPOMA10 - Page 1

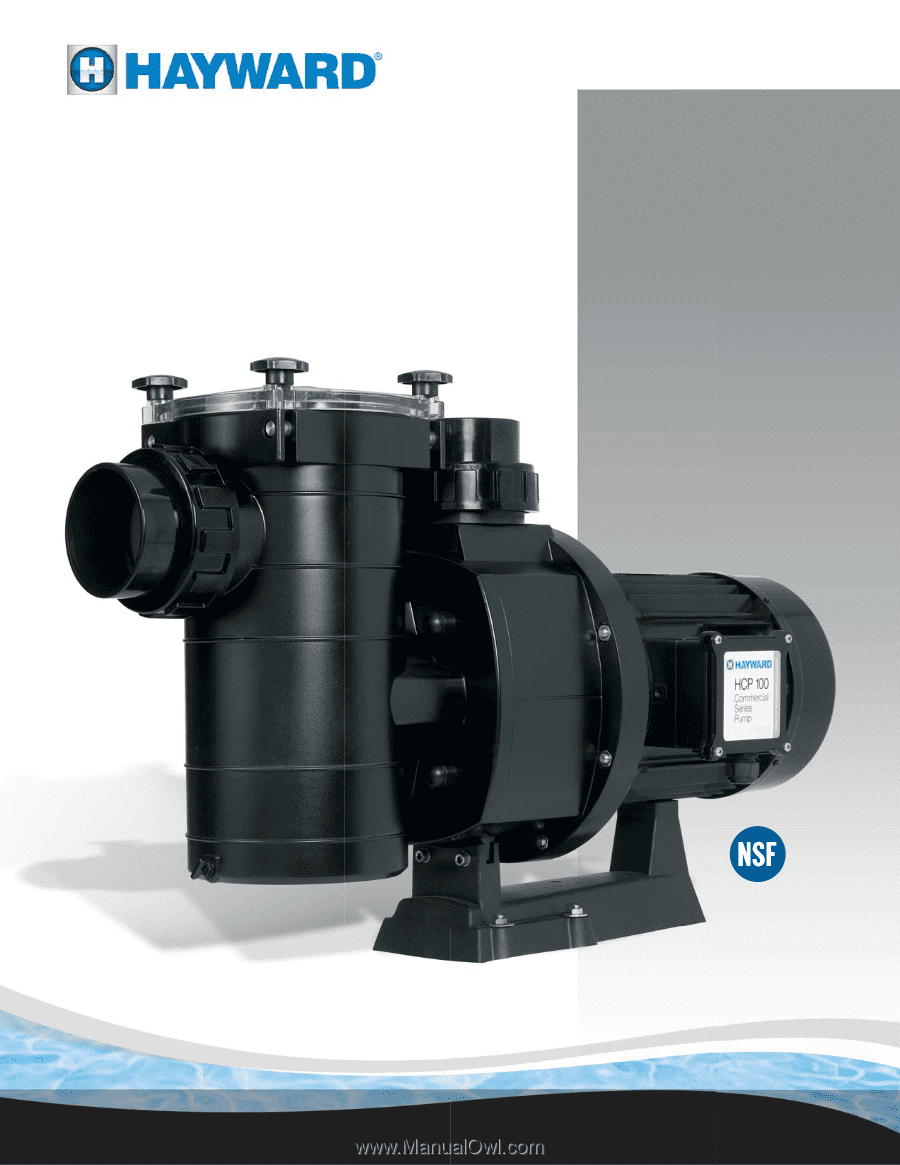

listed ® Models: HCP55 / HCP75 / HCP100 / HCP125 HCP SERIES Commercial Self-Priming Pumps Manual - Hayward HCP Pump | HCP Series LITCPOMA10 - Page 2

Used in the Manual 2.2 Important Safety Instructions 2.3 Nameplate Ratings 2.4 Liability 2.5 Standards 2.6 General Instructions in Relation to User Safety 3. Dimensions 4. Packing, Transport and Storage 4.1 Handle with Care 4.2 Clean-Up 5. Installation 5.1 Location 5.2 Foundation 5.3 HCP Pump Piping - Hayward HCP Pump | HCP Series LITCPOMA10 - Page 3

Operation 8.1 Prior to Start-Up 8.2 Starting/Priming the Pump 8.3 Maintenance 8.4 Storage/Winterization 8.5 Storing Pump for Winterization 9. Maintenance/Conservation - Strainer 10. Assembly/Disassembly/Parts List 11. Troubleshooting 12. Illustrations and Electrical Drawings 13. Exploded Diagram 3 - Hayward HCP Pump | HCP Series LITCPOMA10 - Page 4

AND TRAP - LIGHTER WEIGHT, TECHNOLOGICALLY ADVANCED PUMPS FROM 5.5 TO 12.5 HP. To avoid unneeded service calls, prevent possible injuries, and get the most out of your pump, READ THIS MANUAL CAREFULLY! The Hayward HCP Series Self-Priming Centrifugal Pump is designed for use with commercial swimming - Hayward HCP Pump | HCP Series LITCPOMA10 - Page 5

SAFETY INSTRUCTIONS 2. Safety Instructions This manual contains the necessary instructions for installation, use and maintenance of the HCP Series Self-Priming Pumps. In order to obtain the maximum performance shown by the manufacturer in the Description, it is necessary to fulfill and follow - Hayward HCP Pump | HCP Series LITCPOMA10 - Page 6

, section 3.2. 2.4 LIABILITY Failure to comply with the instructions given by the manufacturer in this manual, in relation to the choice, handling, installation, starting and maintenance of the unit, shall release the manufacturer or distributor from all liability in respect of accidents suffered by - Hayward HCP Pump | HCP Series LITCPOMA10 - Page 7

2.6 GENERAL INSTRUCTIONS IN RELATION TO USER SAFETY Safety during operation of the machinery supplied can only be guaranteed if it is used in accordance with the diagrams shown on page 11. It must never exceed the working conditions and limits given in this manual under Technical Characteristics. - Hayward HCP Pump | HCP Series LITCPOMA10 - Page 8

HCP100 HCP125 All motors: Certified to UL 1004, IP 55 protection, insulation class F. 60 hz., 3.550 R.P.M. Head Loss in Ft - HCP Single Speed Pumps PERFORMACE - PERFORMACE - PERFORMACE - PERFORMACE - GPM HCP55 HCP75 HCP100 HCP125 0 77.4 83.2 87.78 95.9 50 73.3 80.1 85 94.64 100 - Hayward HCP Pump | HCP Series LITCPOMA10 - Page 9

Pump and strainer are heavy. Remove outer carton before trying to move. Check items received against packing list to be sure that all equipment has been received. Inspect for shipping damage. If found, file claim with carrier immediately. ATTENTION The manufacturer clean with wire brush and solvent - Hayward HCP Pump | HCP Series LITCPOMA10 - Page 10

be dismounted horizontally and the air filter vertically (see minimum space diagram in fig. 1, page 22). 5.2 FOUNDATION ATTENTION The foundation must for servicing pump and piping. Choose a solid, flat surface for mounting the pump. It's important to choose an area that has a drain, so that the pump - Hayward HCP Pump | HCP Series LITCPOMA10 - Page 11

UNION FROM POOL SUCTION PLUMBING. MAXIMUM SUCTION LIFT 10'. 4" UNION SUPPORT PIPE 5.4 HCP PUMP PIPING - FLOODED INSTALLATION Figure 5.4 Installation Diagram. NOT TO SCALE. FROM POOL SUCTION PLUMBING ISOLATION VALVES FULL OPEN WHEN PUMPING STRAIGHT RUN AS SHORT AS POSSIBLE BUT AT LEAST 6 TIMES - Hayward HCP Pump | HCP Series LITCPOMA10 - Page 12

and nameplate data (service factor, maximum amperage, etc.) will vary. Consult control manufacturer and motor nameplate on your pump to correctly choose and size motor starter and control equipment for your particular installation. Specific electrical questions or problems should be addressed to - Hayward HCP Pump | HCP Series LITCPOMA10 - Page 13

plate; use size and type wire required by code. Connect motor ground terminal to electrical service ground. Bond motor to pool manufacturer's instructions to reverse. ATTENTION Ensure that the motor shaft turns freely; do not start the pump if it is blocked. For this purpose, HCP Series pumps - Hayward HCP Pump | HCP Series LITCPOMA10 - Page 14

drains run into a single suction line, the single suction line may be equipped with a valve which will shutoff both main drains from the pump. More than one pump can be connected to a single suction line as long as the requirements above are met. 7.4 WATER VELOCITY AND FLOW RATES The maximum water - Hayward HCP Pump | HCP Series LITCPOMA10 - Page 15

GENERAL System piping must be at least equal to size of pump connections. To prevent strain on the pump casing and foundation, pipe and fittings must be aligned to pump without forcing. To avoid strains on the pump, support both suction and discharge pipes independently. See section 5.3. Place these - Hayward HCP Pump | HCP Series LITCPOMA10 - Page 16

. To avoid breaking pump or putting unnecessary strains on pump or strainer body, support pipe independently of pump/strainer. See section Ensure all pump and system components are sealed properly to prevent leaks. 3. Remove any trapped air in the system by fully opening filter manual air relief - Hayward HCP Pump | HCP Series LITCPOMA10 - Page 17

valves are open when pump is running. See Troubleshooting Guide. ATTENTION Wait five (5) seconds before re-starting pump after stopping the pump. Failure to do so may cause reverse rotation of motor and consequent serious pump damage. Close filter manual air relief valve after pump is primed and all - Hayward HCP Pump | HCP Series LITCPOMA10 - Page 18

pump for a long time (see instructions below). Keep motor dry and covered during storage. To avoid condensation/corrosion problems, do NOT cover or wrap pump with plastic film or bags. 8.5 Storing Pump strainer housing. 3. Disconnect pump from mounting pad, wiring system (after power has been turned - Hayward HCP Pump | HCP Series LITCPOMA10 - Page 19

transparent cover must be cleaned with water and neutral soap; "do not use detergents." Do not place the strainer in chemicals. NOTICE Do not allow pump to freeze. Remove strainer cover to allow interior to dry out when storing for the season. When interior is dry, replace cover. Remove drain plug - Hayward HCP Pump | HCP Series LITCPOMA10 - Page 20

beforehand. • Assemble the impeller on the shaft, affixing this with the screw and the O-ring using an allen key nº 8. • At the junction of the pump with the motor, keep in mind that the diffuser flange, and all other connections, must fit into the correct space. To order any spare parts, indication - Hayward HCP Pump | HCP Series LITCPOMA10 - Page 21

IMPROPERLY GROUPED Refer to lead grouping diagram on motor nameplate. FOR VOLTAGE Manufacturer's Instructions for reversing single phase motor. 2. MECHANICAL A. FLOW THROUGH PUMP COMPLETELY Locate and remove obstruction. Refer to Repair Instructions for disassembly. OR PARTIALLY OBSTRUCTED B. PUMP - Hayward HCP Pump | HCP Series LITCPOMA10 - Page 22

TROUBLESHOOTING/ ILLUSTRATIONS AND ELECTRICAL DRAWINGS CAUSE 3. SYSTEM A. PRESSURE REQUIRED BY SYSTEM AT DESIGN FLOW RATE EXCEEDS PRESSURE RATING OF PUMP B. OBSTRUCTION IN SUCTION PIPING C. PRESSURE RATING OF PUMP EXCEEDS PRESSURE REQUIREMENT OF SYSTEM AT DESIGN FLOW RATE D. SUCTION LIFT EXCEEDS 10 - Hayward HCP Pump | HCP Series LITCPOMA10 - Page 23

EXPLODED DIAGRAM 13. Exploded Diagram Figure 4 - (see next page for Key Nos.) 100 62 23 - Hayward HCP Pump | HCP Series LITCPOMA10 - Page 24

HCP SERIES COMMERCIAL SELF-PRIMING PUMPS MANUAL Description Lid Bolt Set Pump Lid Filter Basket Internal O-Ring Set Seal Set Pump Casing Pump Support Drain Plug Set (Qty. of 10) Pump Lid O-Ring HCXP55MOTOR HCXP75MOTOR HCXP100MOTOR HCXP125MOTOR HCXP6024A Hayward Commercial is ready to jump

Models: HCP55 / HCP75 / HCP100 / HCP125

HCP SERIES

Commercial

Self-Priming Pumps

Manual

listed

®