HP BL260c Technologies in HP ProLiant G5 c-Class Server Blades - Page 8

Thermal Logic technologies, Processor socket technology

|

UPC - 883585668663

View all HP BL260c manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 8 highlights

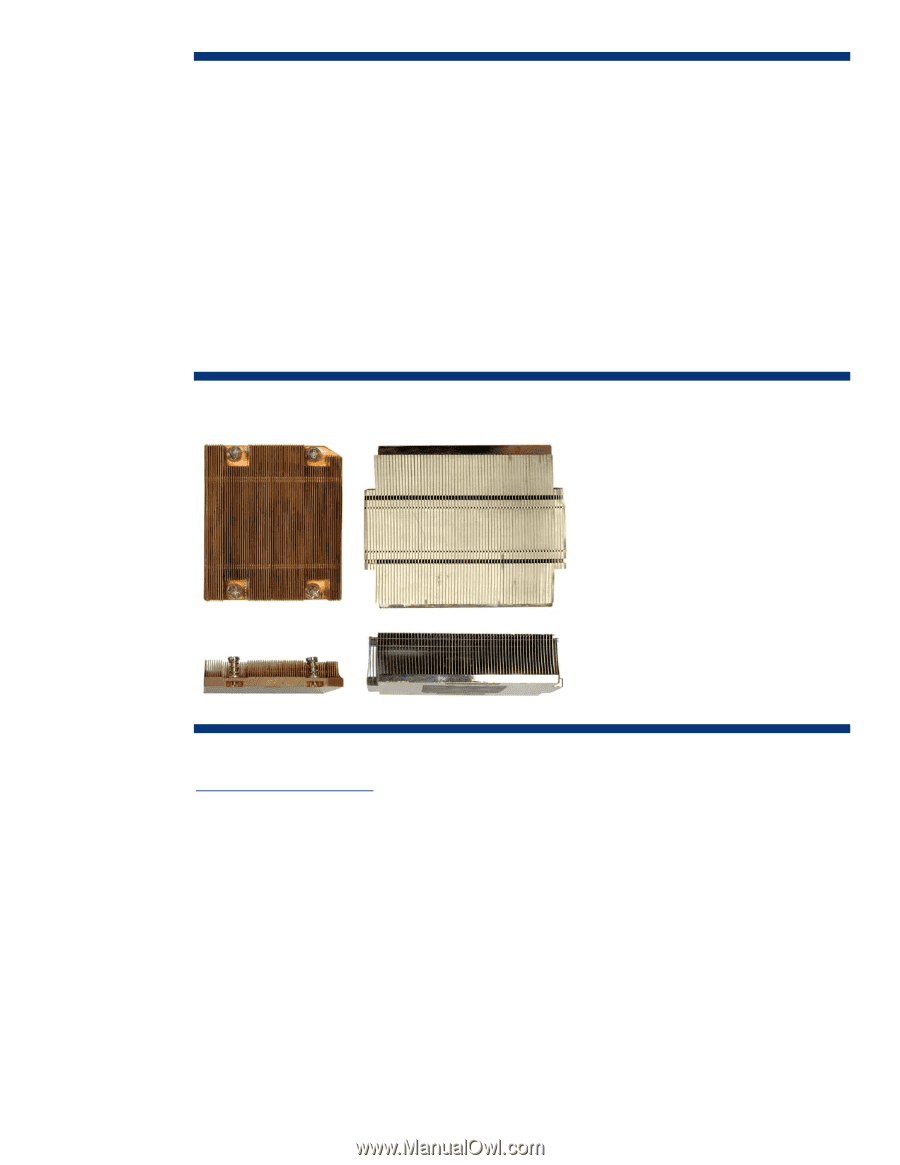

Thermal Logic technologies For ProLiant c-Class server blades, HP designed smaller heat sinks than rack-mount servers use. The server blade heat sinks have vapor chamber bases, thinner fins, and tighter fin pitch than previous designs to achieve the largest possible heat transfer surface in the smallest possible package (Figure 8). The smaller heat sink allows more space on the server blades for DIMM slots and hard drives. Precise ducting on ProLiant c-Class server blades manages airflow and temperature based on the unique thermal requirements of all the critical components. The airflow is tightly ducted to ensure that no air bypasses the server blade and to obtain the most thermal work from the least amount of air moved. Ducting produces high pressure that reduces the amount of required airflow, which in turn reduces the power draw of fans. The lower airflow requirement has the added benefit of optimizing the available data center cooling capacity. Figure 8. Processor heat sink using fully ducted design (left) and traditional heat sink used in a 1U rack-mount server (right) Top view Side view More information about HP Thermal Logic technologies is available on the HP website: www.hp.com/go/thermallogic. Processor socket technology The latest AMD and Intel processors use a processor socket technology called Land Grid Array (LGA). The processor package designs no longer have pins. Instead, the processor package has pads of gold-plated copper that touch processor socket pins on the motherboard. Technicians must be careful when installing processors to avoid damaging the delicate processor socket pins. Because pin damage could require replacing the motherboard, HP engineers developed a special installation tool to simplify processor installation and reduce the possibility of damaging the socket pins (Figure 9). 8