LG LSC27914SB Owner's Manual - Page 124

Practical Work For Heavy Repair

|

View all LG LSC27914SB manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 124 highlights

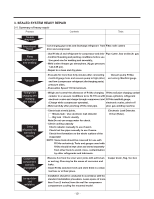

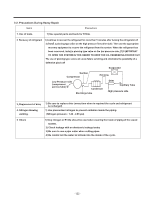

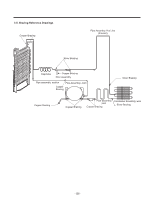

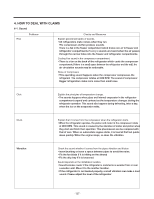

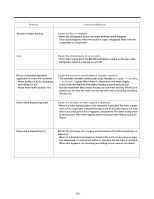

3-3. Practical Work For Heavy Repair Items Precautions 1. Removal of residual refrigerant. Suction Service tube Discharge tube Capillary Tube KEY POINT Observe the sequence for removal of refrigerant. (If not, compressor oil may leak.) 1) Continue to recover the refrigerant for more than 5 minutes after turning the refrigerator off. 2) Install a piercing type valve on the high pressure line (drier side). Then use the appropriate recovery equipment to recover the refrigerant from the system. When the refrigerant has been recovered, install a piercing type valve on the low pressure side. IT IS IMPORTANT TO OPEN THE SYSTEM IN THIS ORDER TO KEEP THE OIL FROM BEING FORCED OUT. The use of piercing type valves will allow future servicing and eliminates the possibility of a defective pinch off. 2. Nitrogen blowing welding. Suction 4 Service tube 3 Discharge tube KEY POINT Welding without nitrogen blowing produces oxidized scales inside a pipe, which Capillary affect performance and 2 Tube reliability of a product. 1 After to be assembled drier (weld 1 and 2 parts) apply nitrogen to high pressure side (0.1~0.2 Kg/cm²) Weld 3 and 4 parts and apply blowing nitrogen to the low pressure side. 3. Replacement of drier. 0.748 ± 0.04 KEY POINT Be sure to check the inserted length of capillary tube when it is inserted. (If inserted too far, the capillary tube will be blocked by the filter.) Inserting a capillary tube Measure distance with a ruler and put a mark(0.748 ±0.04)on the capillary tube. Insert tube to the mark and weld it - 123 -