LG LSC27914SB Owner's Manual - Page 125

Items, Precautions, Pipe Connection, Vacuum Sequence, Charging sequence, KEY POINT, Calculation - electronics

|

View all LG LSC27914SB manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 125 highlights

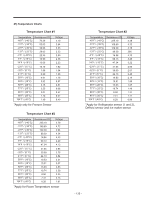

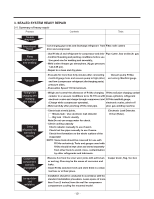

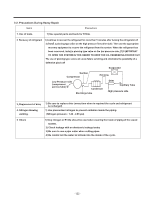

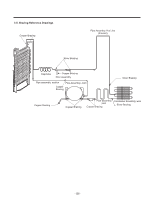

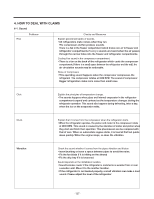

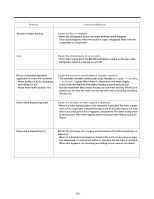

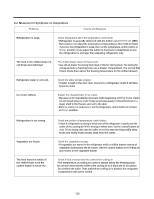

Items 4. Vacuum degassing. Compressor Precautions Evaporator Suction pipe Hot Line Drier Condenser 3 2 1 Blue Low pressure Yellow Red High pressure 5. Refrigerant charging. KEY POINT Vaccum Pump - If power is applied during vacuum degassing, vacuum degassing shall be Pipe Connection more effective. - Run the compressor Connect the red hose to the high pressure side and the blue hose to the while charging the low pressure side. Vacuum Sequence system. It is easier and works better. Open valves 1 and 2 and evacuate for 40 minutes. Close valve 1 . Charging sequence 1) Check the amount of refrigerant supplied to each model after completing vacuum degassing. 2) Evacuate charging canister with a vacuum pump. 3) Measure the amount of refrigerant charged. - Measure the weight of an evacuated charging canister with an electronic scale. - Charge refrigerant into a charging canister and measure the weight. Calculate the weight of refrigerant charged into the charging canister by subtracting the weight of an evacuated charging canister. Indicate the weight of an evacuated charging canister R134a KEY POINT - Be sure to charge the refrigerant at around 25°C [77°F]. - Be sure to keep -5g in the winer and +5g in summer. Calculation of amount of refrigerant charged the amount of refrigerant charged= weight after charging weight before charging (weight of an evacuated cylinder) - 124 -