Rheem P-M406 Operating Instructions - Page 25

HEAT EXCHANGER REVERSAL PROCEDURE - STANDARD MODELS, AFT Models, Millivolt Models, Do not over

|

View all Rheem P-M406 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 25 highlights

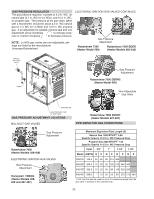

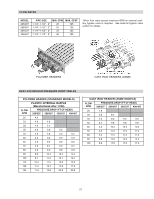

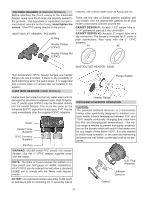

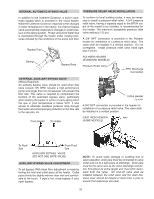

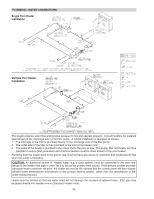

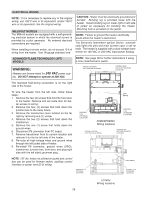

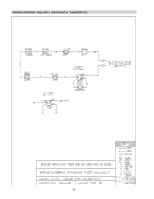

HEAT EXCHANGER REVERSAL PROCEDURE - STANDARD MODELS 1. Remove right and left side access panels (Figure 1). 2. Disconnect wires at high limit, AGS (automatic gas shut-off), and pressure switch on the in/out header (Figure 2). 3. AFT Models: Remove the thermostat temperature sensor by loosening the compression fitting nut (Figure 3). Re-route the sensor to the left side of the heater. 4. Millivolt Models: Remove the temperature sensor bulb and retainer clip from the sensor well (Figure 4). Re-route the sensor bulb to the left side of the heater. 5. Remove (12) bolts holding the inlet/outlet and return headers to the tube sheets. Clean off tube sheet area where the gasket seats. Also clean off the header and the gasket. Apply a non-petroleum-based lubricant to the gasket such as AquaLube. Re-attach the headers to the opposite sides, making sure they are installed in an upright position (Figure 5). Do not over tighten. Torque should not exceed 7 ft/lb. 6. Reconnect high limit, AGS, and pressure switch wires. 7. AFT Models: Insert the temperature sensor into the compression fitting, so that the sensor is flush with the top of the fitting. Tighten 1/2 turn past hand-tight. 8. Millivolt Models: Insert sensor bulb and retainer clip into sensor well. 9. Allow for water flow through the heater and check for leaks. 10. Re-attach access panels to the opposite sides. For ASME Models call your factory representative. Fig. #1 Fig. #2 Fig. #3 Fig. #4 25 Fig. #5