Sanyo PLC-HP7000L RS232C Expand - Page 83

CR_BLENDSTART Command, 10.19 CR_BLENDBLK Command, 10.20 CR_BLENDTESTPAT Command

|

View all Sanyo PLC-HP7000L manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 83 highlights

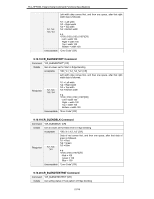

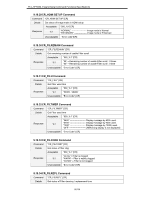

PLC-HP7000L Expand Serial Command Functional Specifications Left width data comes first, and then one space, after that right width data is followed. %1, %2, %3, %4 Unacceptable %1 = Left width %2 = Right width %3 = Top width %4 = Bottom width e.g. "0100_0100_0100_0100"[CR] →Left = width 100 Right = width 100 Top = width 100 Bottom = width 100 "Error Code" [CR] 9.10.18 CR_BLENDSTART Command Command "CR_BLENDSTART" [CR] Details Get all values set for Start in Edge blending Acceptable "000_%1_%2_%3_%4" [CR] Left width data comes first, and then one space, after that right width data is followed. Response %1, %2, %3, %4 Unacceptable %1 = Left width %2 = Right width %3 = Top width %4 = Bottom width e.g. "0100_0100_0100_0100"[CR] →Left = width 100 Right = width 100 Top = width 100 Bottom = width 100 "Error Code" [CR] 9.10.19 CR_BLENDBLK Command Command "CR_BLENDBLK" [CR] Details Get all values set for Black level in Edge blending Acceptable "000_%1_%2_%3" [CR] Response %1, %2, %3 Data of red comes first, and then one space, after that data of green is followed. %1 = Red %2 = Green %3 = Blue e.g. "0100_0100_0100"[CR] →Red = 100 Green = 100 Blue = 100 Unacceptable "Error Code" [CR] 9.10.20 CR_BLENDTESTPAT Command Command "CR_BLENDTESTPAT" [CR] Details Get setting status of Test pattern of Edge blending 83/94