Troy-Bilt TB32 Operation Manual

Troy-Bilt TB32 Manual

|

View all Troy-Bilt TB32 manuals

Add to My Manuals

Save this manual to your list of manuals |

Troy-Bilt TB32 manual content summary:

- Troy-Bilt TB32 | Operation Manual - Page 1

Operator's Manual TB32 EC 2-Cycle Trimmer English - Page 1 Removing Unit From Carton Assemble The Unit 1 2 Remove all contents from the carton. Place shield onto mount bracket. Securely screw 2 shield screws through holes on mount bracket and into shield. Make sure screws - Troy-Bilt TB32 | Operation Manual - Page 2

Service Information 2 Rules for Safe Operation 2 Know Your Unit 3 Assembly Instructions 3 Oil and Fuel Information 3 Starting and Stopping Instructions 4 Operating Instructions 4 Maintenance and Repair Instructions 4 Cleaning and Storage 5 Optional Accessory 5 Troubleshooting Chart - Troy-Bilt TB32 | Operation Manual - Page 3

• 3/8" Socket KNOW YOUR UNIT Spark Plug Muffler Choke Lever Starter Rope Grip On/Off Control Air Filter Cover Shaft Grip Throttle Control Fuel Cap Coupler D-Handle Shaft Housing Primer Bulb Line Cutting Blade Cutting Head Shield ASSEMBLY INSTRUCTIONS OPERATING THE COUPLER The coupler - Troy-Bilt TB32 | Operation Manual - Page 4

. 11). MAINTENANCE AND REPAIR INSTRUCTIONS MAINTENANCE SCHEDULE WARNING: To prevent serious injury, never perform maintenance or repairs with unit running. Always service and repair a cool unit. Disconnect the spark plug wire to ensure that the unit cannot start. Perform these required maintenance - Troy-Bilt TB32 | Operation Manual - Page 5

the carburetor adjusted by an authorized service dealer. MAINTAINING THE SPARK PLUG 1. Stop the engine and allow it to cool. Grasp the spark plug boot firmly and pull it from the spark plug. 2. Clean around the spark plug. Remove the spark plug from the cylinder head with a 5/8-inch socket, turning - Troy-Bilt TB32 | Operation Manual - Page 6

.troybilt.com or www.troybilt.ca Electric Start Feature Fig. 22 TROUBLESHOOTING CAUSE ENGINE WILL NOT START Empty fuel tank The primer bulb wasn't pressed enough Engine is flooded The fuel is old (over 30 days) and/or improperly mixed Fouled spark plug ACTION Fill fuel tank with properly mixed - Troy-Bilt TB32 | Operation Manual - Page 7

TB32 EC Recortador de 2 Ciclos Manual del Operador English - Page 1 Sacar la unidad de la vea la sección Cambiar la línea de corte de este manual. *Éste es asistir a la recarga de Splitline® solamente. Estas instrucciones no son parte de las instrucciones de asamblea rápidas. La línea no necesita - Troy-Bilt TB32 | Operation Manual - Page 8

manijas. • Mantenga las manos, la cara y los pies alejados de todas las partes en movimiento. No toque ni trate de parar el accesorio de corte cuando esté limpio, nuevo y sin plomo. • INDICADOR DE ACEITE Consulte el manual del operador para obtener información acerca del tipo correcto de aceite. - Troy-Bilt TB32 | Operation Manual - Page 9

combustible de mezcla o si su uso es inevitable, tome las precauciones recomendadas. • Use siempre una mezcla fresca de combustible según lo indica su manual del operador. • Use el aditivo especial de combustible STA-BIL® o uno similar • Agite siempre la mezcla de combustible antes de cargarlo en la - Troy-Bilt TB32 | Operation Manual - Page 10

DE ARRANQUE Y APAGADO INSTRUCTIONS DE DÉMARRAGE ADVERTENCIA parte trasera de la unidad. Consulte la sección de Operación del manual del operador del Arrancador Eléctrico o Accesorio de Arranque Eléctrico Opcional Power Start la unidad El accesorio de corte Bump Head™ le permite soltar línea de corte - Troy-Bilt TB32 | Operation Manual - Page 11

Enrolle el hilo ajustado en el sentido que se indica en la parte inferior del carrete interior hasta que queden aproximadamente 6 pulgadas (150 indica, el cabezal de corte funciona de manera incorrecta. Prosiga con la Parte 3 - Instalación del carretel interior. Divisor Ranura Ranuras de retención - Troy-Bilt TB32 | Operation Manual - Page 12

ño para limpiar la parte exterior de la unidad un accesorio de arranque Power Start Bit™, los cuales se - 11 libras (4.5 - 5 kg) Mecanismo de corte Bump Head™ Diámetro de la línea de corte 0.095 pulg (2. manual se basan en la información más reciente disponible en el momento de impresión del manual - Troy-Bilt TB32 | Operation Manual - Page 13

NOTES 13 - Troy-Bilt TB32 | Operation Manual - Page 14

NOTES 14 - Troy-Bilt TB32 | Operation Manual - Page 15

NOTES 15 - Troy-Bilt TB32 | Operation Manual - Page 16

returned directly to the factory will be accepted unless prior written permission has been extended by the Customer Service Department of Troy-Bilt. This limited warranty does not provide coverage in the following cases: A. Tune-ups - Spark Plugs, Carburetor Adjustments, Filters B. Wear items

IMPORTANT: READ THE OPERATOR’S MANUAL THOROUGHLY AND FOLLOW THE SAFE OPERATION PRACTICES WHILE OPERATING THE UNIT.

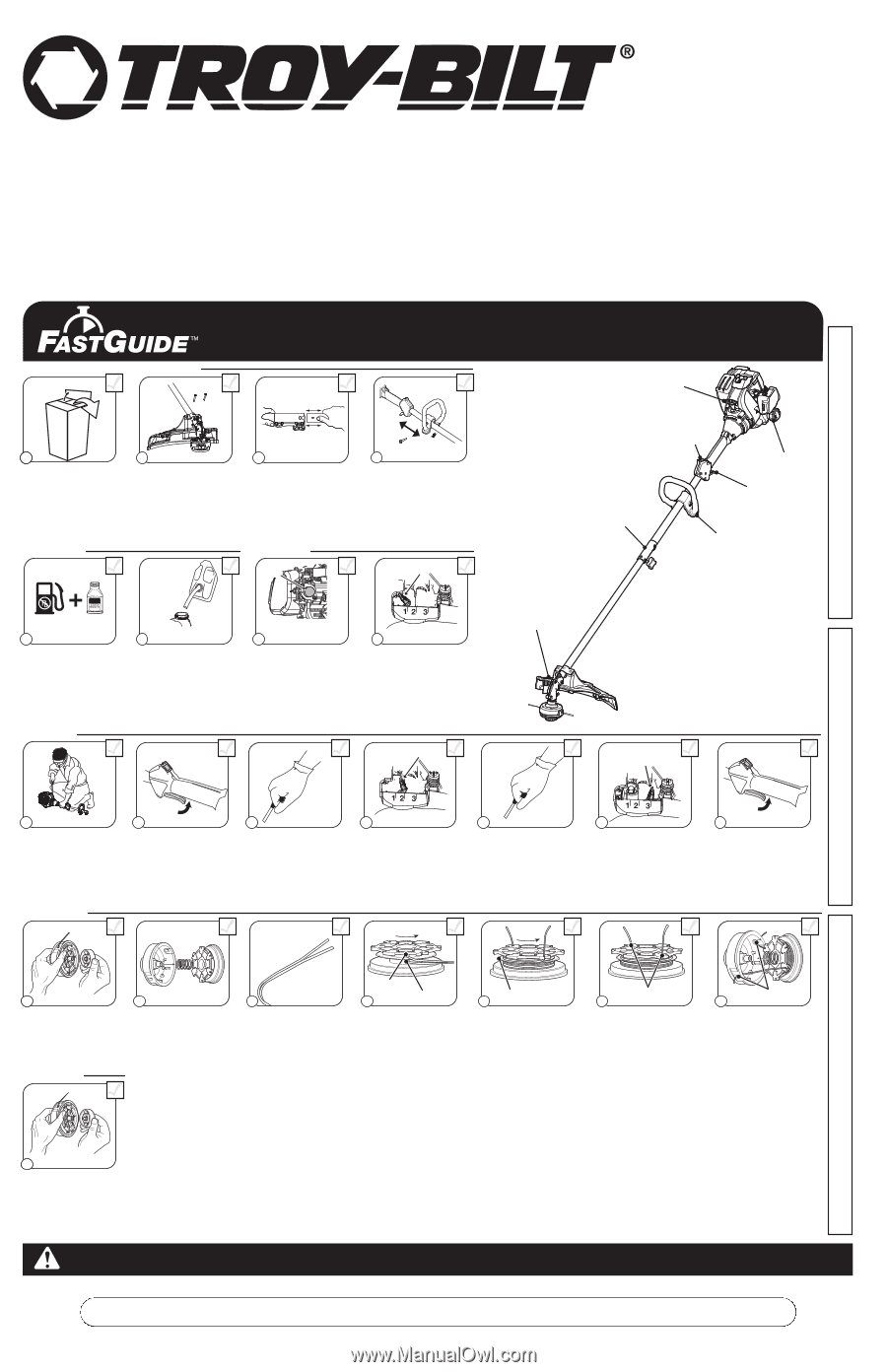

Bump

Knob

Inner

Reel

Outer

Spool

Spring

Top Hole

Bottom Hole

Split Wall

Unscrew the bump knob

counterclockwise.

Remove the inner reel and

spring.

Cut one 6-foot (1.8 m) length

of new 0.095” split line

trimming line. Split each end

about 6 inches (150 mm).

Insert the end of one line into

the top hole and the end of

the other line into the bottom

hole.

Wind the line tightly in the

direction shown on the inner

reel. The split wall will divide

the line. Wind the line until it

is completely divided and

about 6 inches (150 mm) of

line remains.

Insert the two 6-inch sections

into the two .095 holding

slots.

1

1

2

Pass the two line ends

through the eyelets. Place the

spring inside the inner reel.

Insert the inner reel into the

outer spool. Push the inner

reel and outer spool together.

Reloading the Line*

3

4

5

6

7

Hold the inner reel and outer

spool together. Firmly pull the

two line ends to release them

from the holding slots. Screw

the bump knob on clockwise.

Tighten the bump knob

securely.

1

8

For replacement line, call

1–800-828-5500

or go to

an authorized service dealer.

For

single line

installation or

replacement spool

installation instructions, refer to the

Replacing the

Trimming Line

section of this manual.

*This is to assist in the reloading of Splitline® only. These instructions

are NOT part of the fast assembly instructions. Line does not need to

be installed on the initial assembly and start-up.

Reloading the Line

Holding Slots

Eyelets

Removing Unit From Carton

Assemble The Unit

1

1

2

Remove all contents from

the carton.

Remove cap from lower

boom. Push cutting

attachment into coupler.

Turn coupler knob

clockwise to tighten.

Crouch in starting position.

SQUEEZE

and

HOLD

throttle for

ALL

further

steps.

Pull

rope

5 times

.

Move

choke lever to

Position 2

and squeeze

throttle.

Pull

rope

3-5 times

to start

engine.

Run

unit for

30-60

seconds

to warm up.

Continue to squeeze

throttle.

Move

choke lever

to

Position 3

.

9

10

3

Continue to squeeze

throttle.

Run

unit for an

additional 60 seconds

to

complete warm-up. Unit

may be used during this

time.

Starting The Unit

11

12

13

14

15

5 X

3-5 X

Choke Lever

Choke Lever

Place

shield

onto

mount

bracket

. Securely screw

2

shield

screws

through holes on mount

bracket and into shield. Make

sure screws are tightened equally

so there is an equal gap between

bracket and shield on each side.

Starter Rope

Fuel Cap

Throttle Control

On/ Off Switch

D-Handle

Coupler

Cutting Head Shield

Need Help?

Call 1-800-828-5500

Electric Starter or

Power Start Bit Optional!

THESE OPTIONAL ACCESSORIES

ARE SOLD SEPARATELY!

This unit has an alternate starting method

that many find easier to use than pulling a

rope. Please contact a local retailer or call

1-800-828-5500

for more information.

Information may also be found at

www.troybilt.com

DIDN’T START?

Repeat these instructions.

IF

engine fails to start after 2 attempts,

move choke lever to position 3 and pull

the starter rope until engine starts

IF

unit still fails to start, refer to the

operator’s manual for additional starting

and troubleshooting information

ASSEMBLY TOOLS

REQUIRED:

•

Phillips #2 Screwdriver

•

3/8” Socket

Push the handle onto the shaft housing.

The bolt hole should be to the right.

Insert the bolt into the bolt hole.

Tighten the bolt, but not completely.

Move the handle to the location that

provides the best grip. Move the

handle a minimum of

6 inches

away

from the shaft grip. Tighten the bolt

until the handle is secure.

4

Min. 6”

Assemble The Unit

Starting The Unit

Mix thoroughly in separate

fuel can:

– 3.2 fl. oz. of 2-cycle

engine oil

– 1 gallon of unleaded

gasoline (less than 30 days

old)

NOTE:

Do not mix directly in

fuel tank.

Place unit on a level surface.

Fill fuel tank.

Press

primer bulb

10 times

,

or until fuel is visible

5

6

7

Move

choke lever to

Position 1

.

8

Primer

Bulb

10 X

1 Gallon

3.2 oz

40:1

Choke Lever

769-08427 / 00

09/12

Engli

s

h — Page 1

E

s

pañol — Page 7

NEED HELP

?

CALL 1-800-828-5500 IN U.

S

. OR 1–800–668–1238 IN CANADA

TB32 EC

2-Cycle Trimmer

Operator

’s

Manual