Whirlpool WOS51EC7A Installation Instructions - Page 5

Electrical Requirements - wos51ec7as

|

View all Whirlpool WOS51EC7A manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 5 highlights

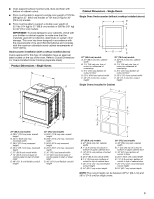

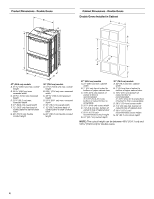

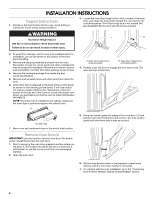

Electrical Requirements If codes permit and a separate ground wire is used, it is recommended that a qualified electrical installer determine that the ground path and the wire gauge are in accordance with local codes. ■ Connect directly to the circuit breaker box (or fused disconnect) through flexible, armored or nonmetallic sheathed, copper cable (with grounding wire). See "Make Electrical Connection" section. Check with a qualified electrical installer if you are not sure the oven is properly grounded. This oven must be connected to a grounded metal, permanent wiring system. Be sure that the electrical connection and wire size are adequate and in conformance with the National Electrical Code, ANSI/ NFPA 70-latest edition or CSA Standards C22.1-94, Canadian Electrical Code, Part 1 and C22.2 No. O-M91-latest edition, and all local codes and ordinances. A copy of the above code standards can be obtained from: National Fire Protection Association 1 Batterymarch Park Quincy, MA 02169-7471 CSA International 8501 East Pleasant Valley Road Cleveland, OH 44131-5575 Electrical Connection To properly install your oven, you must determine the type of electrical connection you will be using and follow the instructions provided for it here. ■ Oven must be connected to the proper electrical voltage and frequency as specified on the model/serial number rating plate. The model/serial number rating plate is located under the control panel on single ovens and under the control panel on the upper oven cavity on double ovens. See the following illustrations. ■ Flexible conduit from the oven should be connected directly to the junction box. ■ Fuse both sides of the line. ■ Do not cut the conduit. The length of conduit provided is for serviceability of the oven. ■ A UL listed or CSA approved conduit connector must be provided. ■ If the house has aluminum wiring, follow the procedure below: 1. Connect a section of solid copper wire to the ends of the flexible conduit leads. 2. Connect the aluminum wiring to the added section of copper wire using special connectors and/or tools designed and UL listed for joining copper to aluminum. Follow the electrical connector manufacturer's recommended procedure. Aluminum/copper connection must conform with local codes and industry accepted wiring practices. For power requirements for models WOS51EC7A, WOS51EC0A, WOD51EC7A, WOD51EC0A, WOS92EC7A, WOS92EC0A, WOD93EC7A, WOD93EC0A, MEW7527A, MEW7530A, MEW7627A, MEW7630A, MEW9537A, MEW9627A, MEW9530A, and MEW9630A, refer to the following table. Voltage Single Single Double Double Thermal Convect Thermal Convect 240 VAC 3690 W 3720 W 7370 W 7400 W 208 VAC 2790 W 2820 W 5580 W 5610 W A A 240 VAC 15.4 A 15.5 A 30.7 A 30.8 A 208 VAC 13.4 A 13.6 A 26.8 A 27.0 A For power requirements for models KEBK171B, KEBK101B, KEBK276B, KEBK206B, KEBS179B, KEBS109B, KEBS277B, KEBS279B, KEBS207B, and KEBS209B, refer to the following table. Single Oven A. Model/serial number plate Double Oven A. Model/serial number plate ■ Models rated from 7.3 to 9.6 kW at 240 volts (5.4 to 7.4 kW at 208 volts) require a separate 40-amp circuit. Models rated at 4.8 kW and below at 240 volts (3.6 kW and below at 208 volts) require a separate 20-amp circuit. ■ A circuit breaker is recommended. Voltage 240 VAC 208 VAC 240 VAC 208 VAC Single Thermal 4090 W 3099 W 17.1 A 14.9 A Single Convect 4120 W 3122 W 17.2 A 15.0 A Double Thermal 8170 W 6190 W 34.1 A 29.8 A Double Convect 8200 W 6212 W 34.2 A 29.9 A 5