Ariens Compact 22 Owners Manual - Page 21

Check Clutch Operation, Adjustment, Clean Engine, Check Engine Oil, Check Tire Pressure - engine manual

|

View all Ariens Compact 22 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 21 highlights

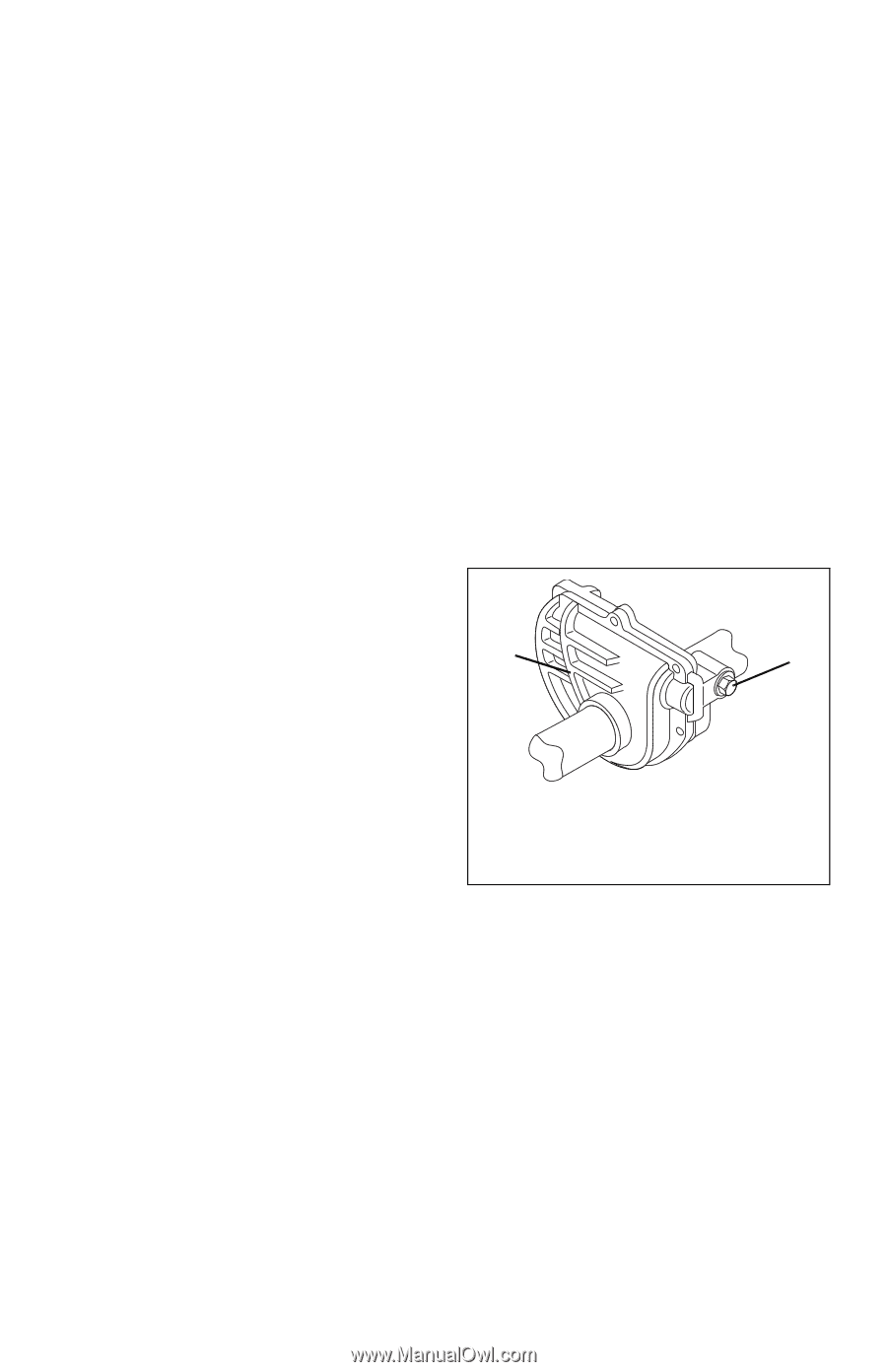

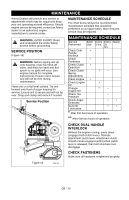

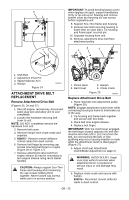

CHECK CLUTCH OPERATION Auger / impeller must stop within 5 seconds when attachment clutch/impeller brake lever is released. Wheels must stop quickly when traction drive clutch lever is released. If clutches do not engage or disengage properly, adjust or repair before operation (see Attachment Clutch/Brake Adjustment on page 27 and Traction Drive Clutch Adjustment on page 29). CHECK CLUTCH SPRING ADJUSTMENT Make sure the attachment clutch and traction drive clutch are adjusted to the range specified in Attachment Clutch/Brake Adjustment on page 27 andTraction Drive Clutch Adjustment on page 29. CLEAN ENGINE Refer to Engine Manual for detailed instructions. CHECK ENGINE OIL The engine crankcase oil should be checked every 5 hours of operation. Oil level MUST be maintained in safe operating range on dipstick at all times or engine damage will result (See Engine Manual). Park unit on a level surface. Refer to Engine Manual for detailed instructions. CHANGE ENGINE OIL Change oil after first 2 hours of operation, thereafter change oil every 25 hours (more often if required). Refer to Engine Manual for detailed instructions. Run engine just prior to changing oil. Warm oil will flow more freely and carry away more contamination. Remove the oil drain plug from the rear of the unit and tip the unit back to help drain all the oil. CHECK TIRE PRESSURE Keep tires at pressure listed on the tire sidewall. (see Check Tire Pressure on page 11). CHECK AUGER GEARCASE (Figure 17) IMPORTANT: Proper oil level must be maintained. Gear cases are filled to the correct level at the factory. Unless there is evidence of leakage, no additional lubricant should be required. Check oil level each season or every 25 hours of operation. To ensure adequate lubricant level: 1. Remove filler plug (Figure 17). Lubricant must be at least up to bottom of lubricant filler hole with unit resting on a levelsurface. 2. Add lubricant if required. Allow oil to drain to level of plug and replace plug. IMPORTANT: Use only Ariens L-3 synthetic severe duty gear lube (Part Number 00068800). NOTE: Gearcase filler plug may require an application of Loc-Tite® 565 thread sealant with repeated servicing. If Loc-Tite® 565 is not available, use PTFE pipe sealing tape on the filler plug. 1 2 1. Auger Gearcase 2. Filler Plug Figure 17 OS8195 GB - 21