Bernina 1011 Manual - Page 48

Maintenance, Cleaning, oiling

|

View all Bernina 1011 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 48 highlights

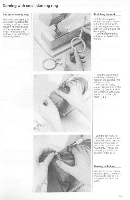

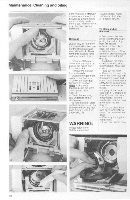

Maintenance: Cleaning and oiling Mos II the machine is stored in A Cold roam it should be brought to a warm room approximately one hour nefore use, to restore the oil in the bearings to a 9.40 state. To cal the hock Apoly 1-2 drops of od after 3-4 hours' sewing =end oil Cleaning Sewing, Ilutt from the thread will collect under the stitch Plate and around the hook These remnants must be removed born lime to time. - (Disconnect the ma. Chine from :he mains by pixting The mains plug from Ire socket - Remove the presser foot and needle - Open the hinged front cover on the bee arm Lower the feed-Mg. Set knob to positron j. Using both thumbs, press the stitch date up and back (Fig 1) - Crean the feeclgog and underside of the stitch plate. - To refit the stitch plate on the free arm, insert the stitch plate from the rear. push forward until it engages (Fig 2) WARNING: - Disconnect the machine from the mains by pulling the maw* Plug MOMII* socket - Take out the bobbin case. see page 4. - Vlfith the thumb of the left hand. press the lower release lever to Ina len (Fig 3) - Fold clown the semispherical locking strap with the black hook race cover - Take out the hook - Clean the top and Cot- ton) of the hook race with Pie cleaning blush and Cotton Cloth Never use a screwdrner. scisSOIS to remove remnants of thread. - Lightly oil the hook race with 1-2 drops Of oil (Fig 4) Insert the hook n necessary, turn the handwheel until the nook driver is on the lett (Fig. 5) - Close the black hack race cover and locking gstrap The Da* must enage. - oleo by turning the nandvinnel - insert the bobbin case. 4 5 a