Bernina 730 Manual - Page 25

Forward, Backward, Sewing, Adjustment, different, Stitch, lengths, airogOs., remove, machine

|

View all Bernina 730 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 25 highlights

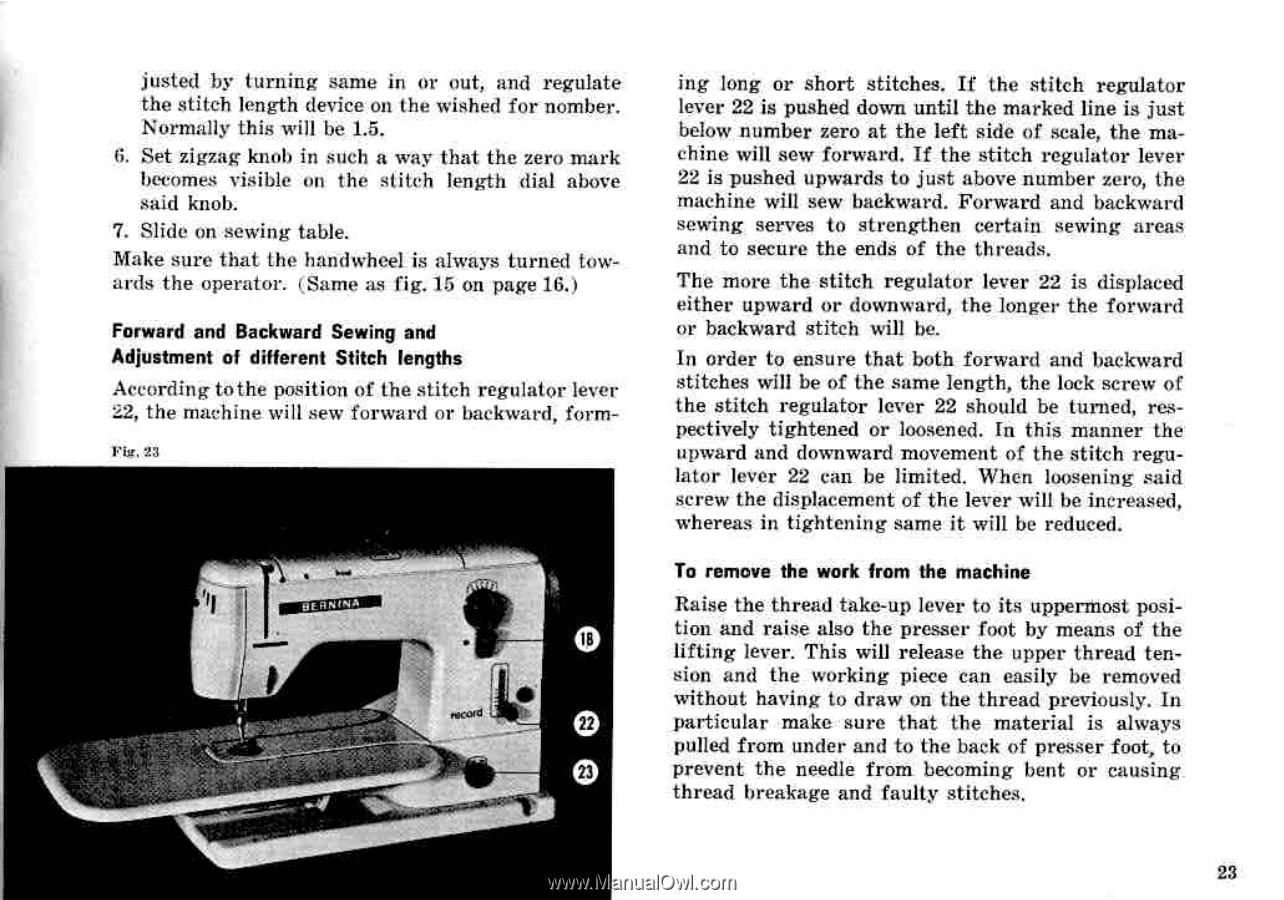

justed by turning same in or out, and regulate the stitch length device on the wished for nomber. Normally this will be 1.5. 6. Set zigzag knob in such a way that the zero mark becomes visible on the stitch length dial above said knob. 7. Slide on sewing table. Make sure that the handwheel is always turned towards the operator. (Same as fig. 15 on page 16.) Forward and Backward Sewing and Adjustment of different Stitch lengths According to the position of the stitch regulator lever 22, the machine will sew forward or backward, form- lig, 23 lootairogOs. wad ing long or short stitches. If the stitch regulator lever 22 is pushed down until the marked line is just below number zero at the left side of scale, the machine will sew forward. If the stitch regulator lever 22 is pushed upwards to just above number zero, the machine will sew backward. Forward and backward sewing serves to strengthen certain sewing areas and to secure the ends of the threads. The more the stitch regulator lever 22 is displaced either upward or downward, the longer the forward or backward stitch will be. In order to ensure that both forward and backward stitches will be of the same length, the lock screw of the stitch regulator lever 22 should be turned, respectively tightened or loosened. In this manner the upward and downward movement of the stitch regulator lever 22 can be limited. When loosening said screw the displacement of the lever will be increased, whereas in tightening same it will be reduced. To remove the work from the machine Raise the thread take-up lever to its uppermost position and raise also the presser foot by means of the lifting lever. This will release the upper thread tension and the working piece can easily be removed without having to draw on the thread previously. In particular make sure that the material is always pulled from under and to the back of presser foot, to prevent the needle from becoming bent or causing thread breakage and faulty stitches. 23