Bosch 1803EVS Operating Instructions - Page 10

Grinding Operations - 5 angle grinder

|

UPC - 000346302431

View all Bosch 1803EVS manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 10 highlights

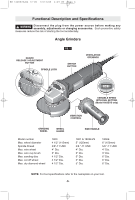

BM 1609929J64 12-05 12/12/05 4:07 PM Page 10 ELECTRONIC FEEDBACK CIRCUITRY (EFC) (Models 1803EVS & 1806E only) The internal electronic feedback system provides a "soft start", which will reduce the stresses that occur from a high torque start. The system also helps to keep the no load speed virtually constant between no-load and load conditions. KICKBACK STOP Your tool is equipped with a kickback stop feature. This feature shuts of the tool automatically if the tool stalls, or the wheel encounters excessive force. To resume operation, TURN ON/OFF SWITCH TO THE OFF POSITION, THEN RESTART THE TOOL. RESTART PROTECTION The restart protection feature was designed to help prevent accidental startups after the power has been interrupted. To resume operation if this occurs, TURN ON/OFF SWITCH TO THE OFF POSITION, THEN RESTART THE TOOL. OVERLOAD PROTECTION (Models 1803EVS & 1806E only) Your tool is equipped with overload protection to protect the motor. If the tool stops during operation TURN OFF SWITCH IMMEDIATELY and allow the motor to cool for about 30 seconds by running at no-load. If the overload protection stops the tool repeatedly, excessive force is causing the tool to overload. Don't press so hard and let the tool do the work. VARIABLE SPEED WITH DIAL SETTING (1803EVS ONLY) Your tool is also equipped with a variable speed dial. The grinder's RPM can be preset from zero to maximum nameplate rated RPM by rotating the dial on the motor housing. If tool is running at a set speed for extended periods of time, it may be necessary to run the tool at no- load full speed to cool the motor. Dial Setting Approx. RPM 1 (2800) 2-3 (5300-7500) 3 (7500) 4-6 (8800-11000) 6 (11000) Application Material Polishing Plastic Attachment Lambswool bonnet felt polishing disc, or buffing disc. Precision grinding Grinding disc of metal tools Solid wood & paint removal Sanding disc Brushing wood Cup brush Removing rust from metal Grinding metal or stone Roughing metal Sanding disc Grinding disc Roughing disc Cutting stone Cutting disc Grinding Operations SELECTING GRINDING WHEELS ! WARNING Before using a grinding wheel, be certain that its maximum safe operating speed is not exceeded by the nameplate speed of the grinder. Do not exceed the recommended wheel diameter. DISC GRINDING WHEELS Grinding wheels should be carefully selected in order to use the grinder most efficiently. Wheels vary in type of abrasive, bond, hardness, grit size and structure. The correct type of wheel to use is determined by the job. Use disc grinding wheels for fast grinding of structural steel, heavy weld beads, steel casting, stainless steel and other ferrous metals. GRINDING TIPS Efficient grinding is achieved by controlling the pressure and keeping the angle between wheel and workpiece at 10° to 15°. If the wheel is flat, the tool is difficult to control. If the angle is too steep, the pressure is concentrated on a small area causing burning to the work surface. ! WARNING Excessive or sudden pressure on the wheel will slow grinding action and put dangerous stresses on the wheel. When grinding with a new wheel be certain to grind while pulling tool backwards until wheel becomes rounded on its edge. New wheels have sharp corners which tend to "bite" or cut into workpiece when pushing forward. -10-