Bosch 1803EVS Operating Instructions - Page 8

Masonry Cutting Wheel Assembly, Disc Grinding Wheel Assembly

|

UPC - 000346302431

View all Bosch 1803EVS manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 8 highlights

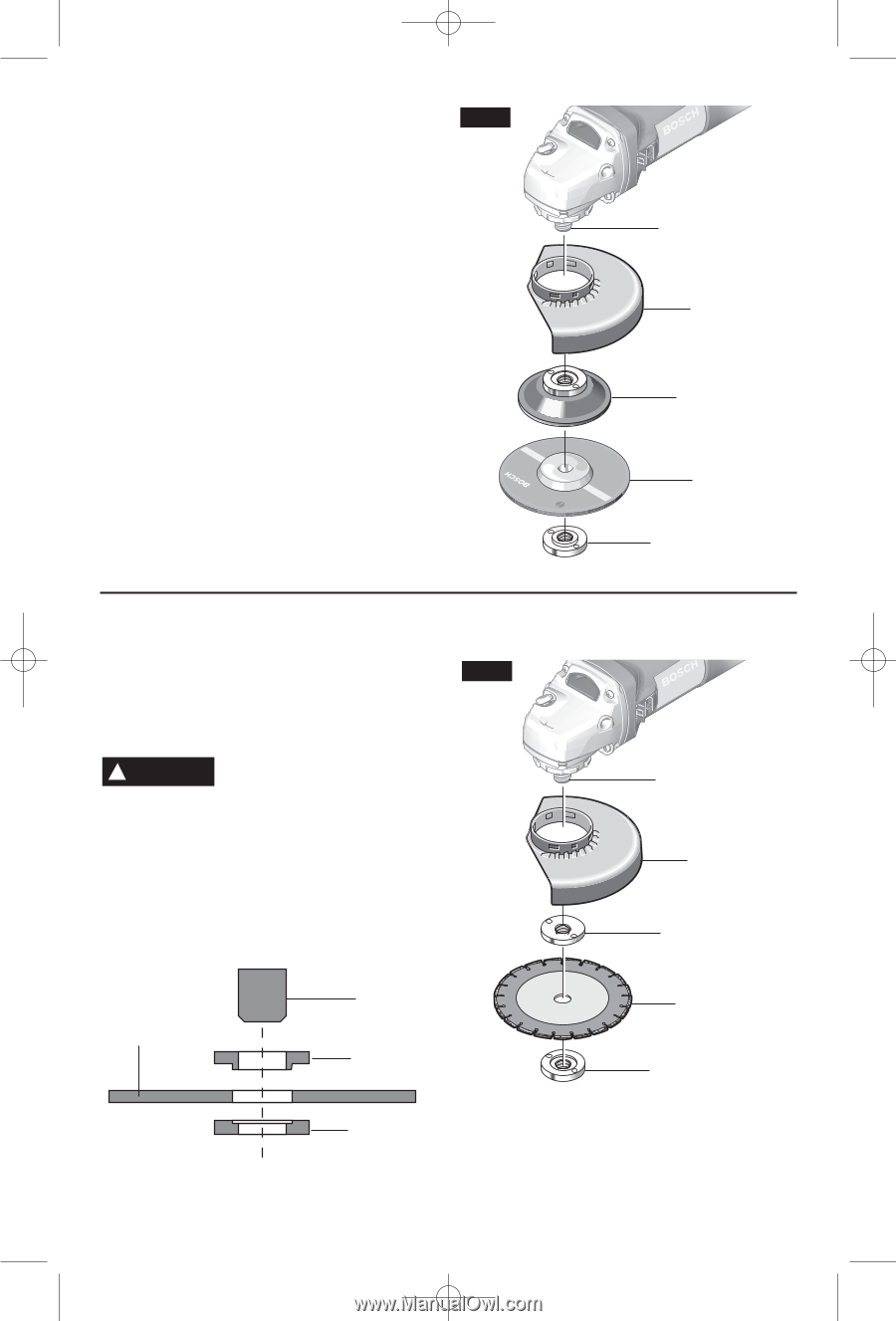

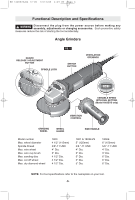

BM 1609929J64 12-05 12/12/05 4:07 PM Page 8 Disc Grinding Wheel Assembly (Model 1806 only) Disconnect tool from power source. Be sure that wheel guard is in place for grinding. When using spin-on grinding wheels, thread directly onto the spindle. When using mounting wheels, thread BACKING FLANGE onto spindle, then place GRINDING WHEEL on the spindle. Thread on the lock nut and tighten nut using a lock nut wrench provided with adapter kit, while holding the spindle lock in (Fig. 4). TO REMOVE: Reverse procedure. FIG. 4 SPINDLE WHEEL GUARD BACKING FLANGE GRINDING WHEEL LOCK NUT Masonry Cutting Wheel Assembly For cutting masonry materials like brick, tile, stone, etc., it is best to use a dry diamond cutting wheel. Use only lock nut and flange with equal diameters. The wheel guard must be used with a dry diamond cutting wheel. ! WARNING Do not use water or other cooling fluid with this tool for cutting. Disconnect tool from power source. Be sure that wheel guard is in place for grinding. Place BACKING FLANGE and DRY DIAMOND WHEEL on the spindle. Thread on the lock nut and tighten nut using the supplied lock nut wrench, while holding the spindle lock in (Fig. 5). TO REMOVE: Reverse procedure. FIG. 5 SPINDLE WHEEL GUARD BACKING FLANGE DRY DIAMOND WHEEL SPINDLE BACKING FLANGE DRY DIAMOND WHEEL LOCK NUT LOCK NUT When cutting, make only small passes through workpiece at a time. Be aware that "Kickback" can occur at any time. Keep both hands on tool for maximum control. -8-