Bosch WTMC8521UC Installation and Use & Care (all languages) - Page 8

Exhaust, connection

|

UPC - 825225852322

View all Bosch WTMC8521UC manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 8 highlights

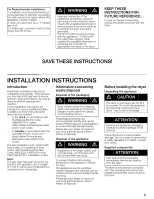

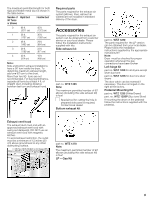

d WARNING d Do not use copper pipes and tubing if connected to natural gas. The connection may be different, according to the supply line type, size and location. If local codes permit, use a flexible stainless steel connector (Design certified by the America Gas Association or CSA International) to connect the dryer. 1 2 To reduce the distance between body sheet and wall the gas pipe of itnhsetadllraye3r/.8" elbow on 1 ć gas pipe (3/8" male pipe thread) 2 ć 3/8" elbow Exhaust air connection d WARNING d 1. To reduce the risk of fire, this dryer MUST BE EXHAUSTED OUTDOORS. 2. To reduce the risk of fire, do not use ductwork longer than recommended. 3. DO NOT use a plastic or nonĆmetal duct with this dryer. 4. DO NOT use a duct smaller than 4 inches in diameter. 5. DO NOT use exhaust hoods with magnetic latches. 6. DO NOT exhaust the dryer into a chimney, furnace cold air duct, attic, crawl space, or any other ductwork used for venting. 7. DO NOT install a flexible duct in an enclosed wall, ceiling or floor. 8. DO NOT crush or kink the duct. 9. Do clean and inspect the exhaust system on a regular basis; at least once a year. 10. The exhaust duct must terminate in a manner to prevent back drafts or entry of birds or other wildlife. The Bosch dryers must be vented outdoors. To prevent buildĆup of moisture and accumulation of lint indoors, as well as to maintain maximum drying efficiency, it is recommended that the dryer is vented outdoors. Exhaust air outlet on the dryer The dryer is delivered with an exhaust air outlet on the rear of the appliance. To take account of the spatial requirements and an existing exhaust air system, the following connection options are possible for the exhaust air outlet: - on right side of the appliance, - on the underside of the appliance. 3 ć Exhaust air outlet on the underside of the appliance (optional) Special exhaust air connections must be obtained from our customer service for either connection type (see page 11). - Side air exhaust - Bottom air exhaust A qualified technician should change the exhaust air outlet to the optional connection location. Ductwork To ensure optimum performance, the ducting system of the dryer should be as short as possible with a minimum number of elbows. Your dryer will work best when the venting system has as few air flow restrictions as possible. Exhaust ducting which is longer than recommended may extend drying time, cause lint to accumulate and affect dryer performance and dryer life. FourĆinch (approx. 100 mm) diameter ducting should be used. Use either rigid metal or flexible metal ducting material. DO NOT use plastic or nonĆmetal duct with this dryer. DO NOT assemble the ductwork with screws or fasteners that extend into the duct. They will serve as an accumulation point for lint. Joints should be secured with aluminum tape. 2 1 3 1 ć Exhaust air outlet on the rear of the appliance (standard) 2 ć Exhaust air outlet on the side (optional) All joints should be tight to avoid leaks. The male end of each duct section must point away from the dryer. Whether connecting to an existing venting system or a new venting system, make sure that all ducting is clean and free of lint. 8