Brother International LK3-B430 Service Manual - Page 28

Clutch, timing, adjustment, Start, lever, position

|

View all Brother International LK3-B430 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 28 highlights

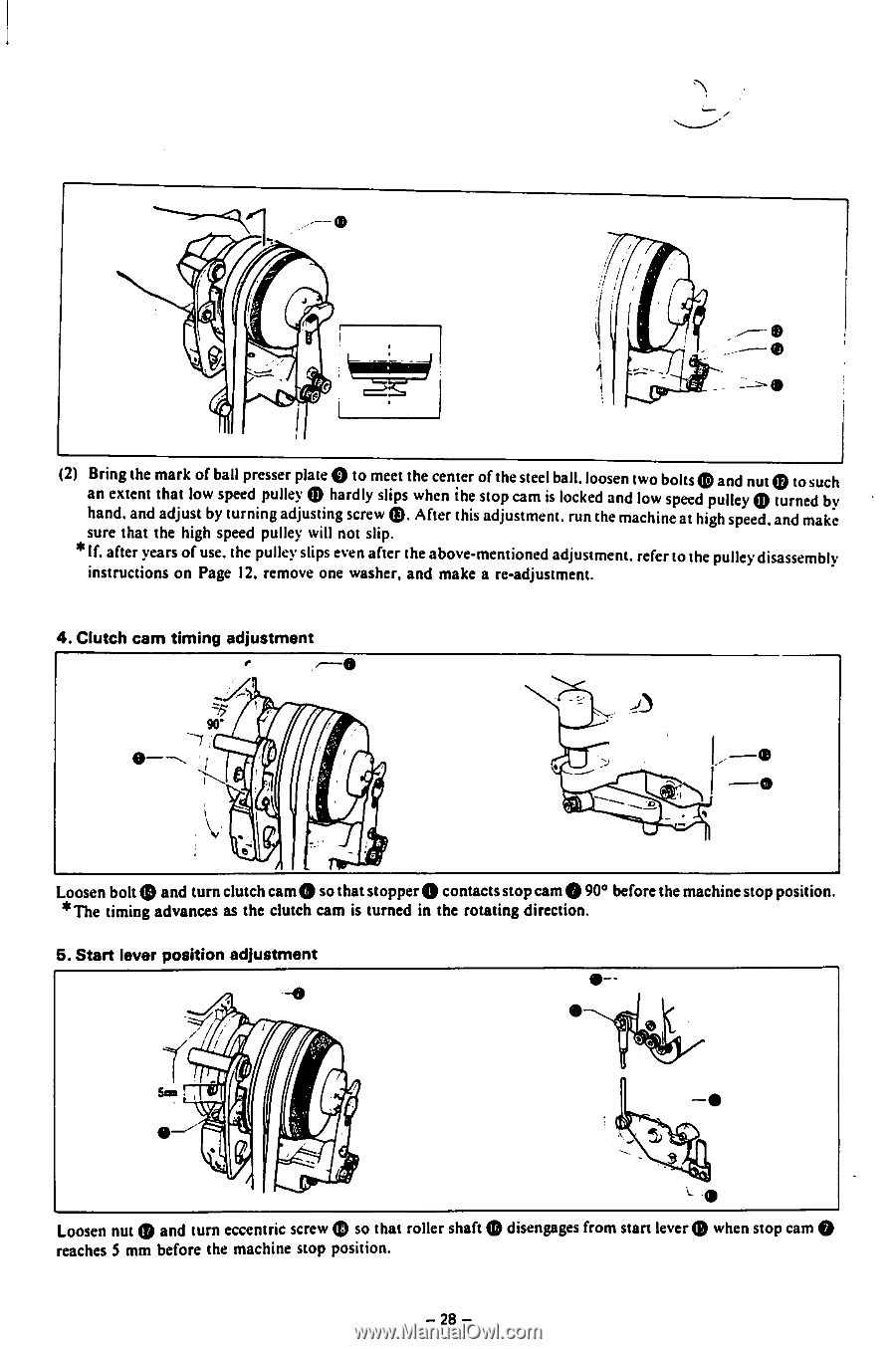

--- 0 ® (2) Bring the mark of ball presser plate 0 to meet the center of the steel ball. loosen two bolts 0 and nut to such an extent hand, and that low speed pulley ® hardly slips adjust by turning adjusting screw S. when After the stop cam is locked and low speed pulley m this adjustment, run the machine at high speed, turned by and make sure that the high speed pulley will not slip. * If. after years of use, the pulley slips even after the above-mentioned adjustment, refer to the pulley disassembly instructions on Page 12, remove one washer, and make a re-adjustment. 4. Clutch cam timing adjustment 0- 22i 0 0 Loosen bolt and turn clutch cam so that stopper 0 contacts stop cam 90° before the machine stop position. *The timing advances as the clutch cam is turned in the rotating direction. 5. Start lever position adjustment 0-- -0 Loosen nut 0 and turn eccentric screw 0 so that roller shaft 0 disengages from start lever ® when stop cam 0 reaches 5 mm before the machine stop position. - 28 -