Canon PIXMA iP5200 Service Manual - Page 47

FAQ

|

View all Canon PIXMA iP5200 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 47 highlights

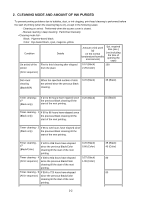

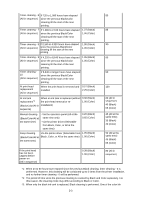

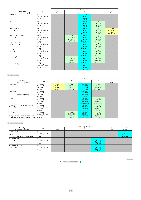

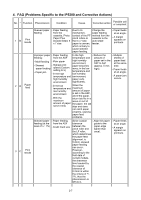

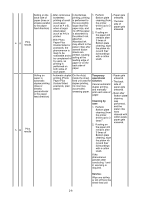

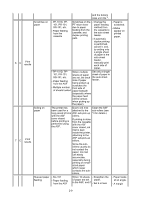

4. FAQ (Problems Specific to the iP5200 and Corrective Actions) No. * Function Phenomenon Condition Cause Corrective action Possible call or complaint Skewed paper - Paper feeding Due to its Change the - Paper feeds feeding from the mechanism, paper feeding at an angle. 1 B Print results cassette, Photo Paper Plus Double Sided, 5 x 7 size contact of the PF pinch rollers to the 5 x 7 size paper is uneven, method from the cassette to the auto sheet feeder. - A margin appears on printouts. which is likely to cause skewed paper feeding. 2B Paper feed Improper paper - Paper feeding In the high feeding: from the ASF temperature and - Multi-feeding - Plain paper - Skewed - Highest print paper feeding speed (Custom setting to 5) - Paper jam - In the high high humidity environment, paper becomes wavy; in the low temperature and low humidity temperature and environment, high humidity paper curls environment significantly. - Reduce the - Multiple amount of sheets of paper set in the paper feed ASF to half at the same (approx. 5 mm time. high). - Paper feeds at an angle. - A paper jam occurs. - In the low When the temperature and maximum low humidity amount of paper environment is set in the ASF, and if the paper- - With the return tab fits in a maximum wave or curl of amount of paper the paper, the tab set (13 mm) slips and does not catch paper properly, causing paper feed problems. Skewed paper - Paper feeding Since coaxial - Align the paper - Paper feeds feeding (at the from the ASF tolerance guide to the at an angle. level of +/- 1%) - Credit Card size between the pinch roller and the LF roller, which determines paper edge tighter than usual. - A margin appears on printouts. the paper feed alignment, is 0.2mm, skewed paper feeding can occur. 3 C Print results However, according to the field data of current models, the skewness level caused by the coaxial tolerance of 0.2mm is within the criteria of +/- 1%, thus the phenomenon is left as is. 2-7