Craftsman 17540 Operation Manual - Page 27

OFFEED, Figs., 17and17a, Theproper

|

View all Craftsman 17540 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 27 highlights

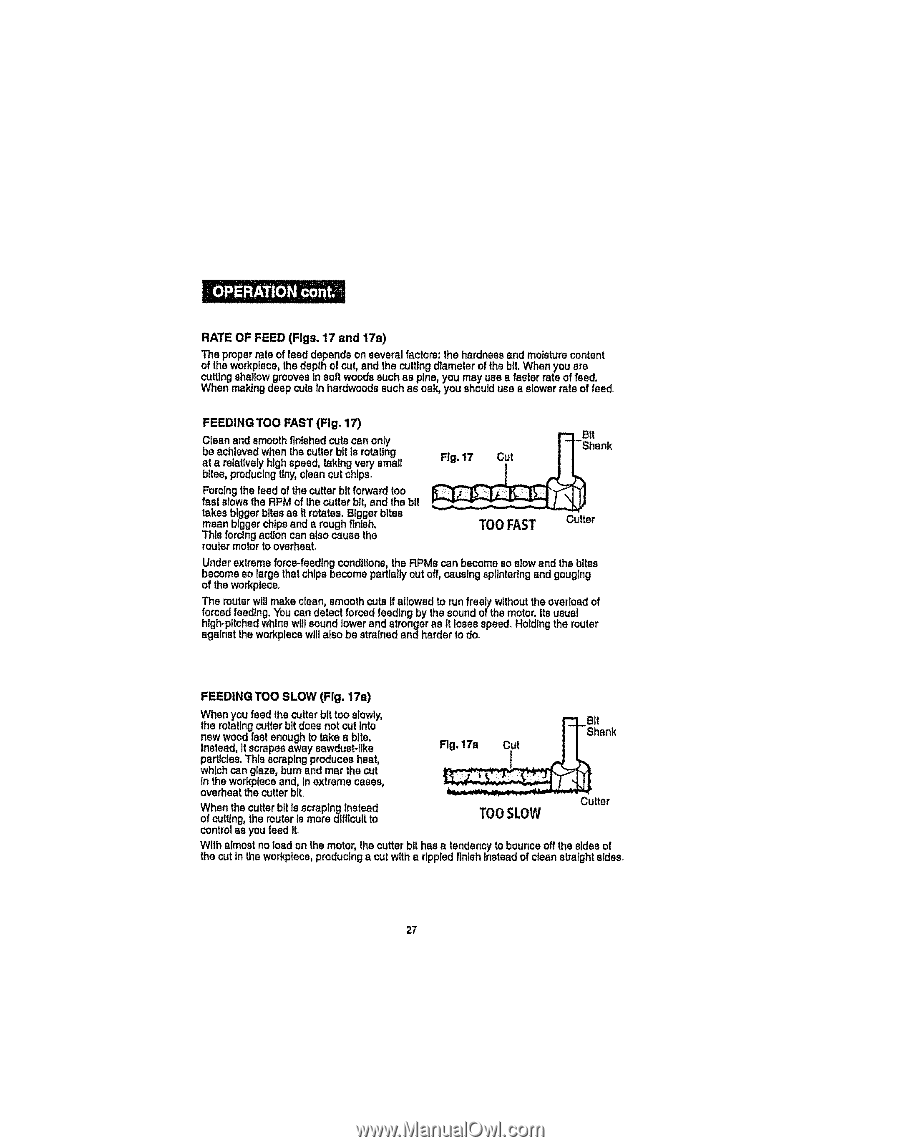

RATOEFFEED(Figs1.7and17a) Theproperrate of teed depends on several factors:the hardnessand moisture content of theworkplace, the depth of cut, and the cutting dEameterof the bit, When you are cuttingshaliow groovesIn soft woods suchas pine, you may use a faster rate of feed, When making deep cutstn hardwoodssuch as oak, you should use a slower rate of feed_ FEEDINGTOO FAST (Fig. 17) Clean and smooth finished cutscan only be, achieved when the cutter bitis rotating at a retat{valyhighspeed, taking veryemaff bites, producingtiny,clean cut chips. Fumingthe feed of the cutter bit forward too fast slowsthe RPM of the cutterbit, and the bit takes bigger bites as It rotates, Bigger bites mean biggerchips and a rough finish, This forcing acUon can also cause the router motorto overheaL m..r,z r_,,_ "'_"- v_'" TOO FAST r"J_B_t ! _1 Shank == II cutter Under extremeforce-feeding conditions,the RPMs can becomeso slow and the bites become so large that chips become partiallycut off, causingsplintering and gouging of theworkpiece_ The muterwilmlake crean,smooth cutsIfallowedtorunfreelwyithoutheovedoadof forced feeding. You can detect forced feeding by the sound of the motor, its usual hfgh-pRchedwhine witrsound lower and strongeras it loses speed. Holding the router against the workplacewilt also be strained and harder todo_ FEEDING TOO SLOW (Fig. 17n) When you feed the culter bit too slowly, the rotatingcutterbit does not cut Into new wood fast enough 1otake a bite, Instead, it scrapes away sawdusFIIke partlcles.Thisscraping produces heat, whichcan glaze, bum and mar the cut in the workpleceend, in extreme cases, overheat the cutterbit, When the cutterbit Isscraping Instead of cuffing,the muteris more difficult to r-j_B_t F_ll TOOSLOW hank Cutter controlas you feed it, With almostno toed on the motor, the cutterbtl has a tendencyto bounce off the sides of the cut In the workplace, producinga cutwith a rippledfinishInstead of clean straight sides. 27