Craftsman 17540 Operation Manual - Page 30

REPLACEMENT, OFCARBON, BRUSHES, Replacement

|

View all Craftsman 17540 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 30 highlights

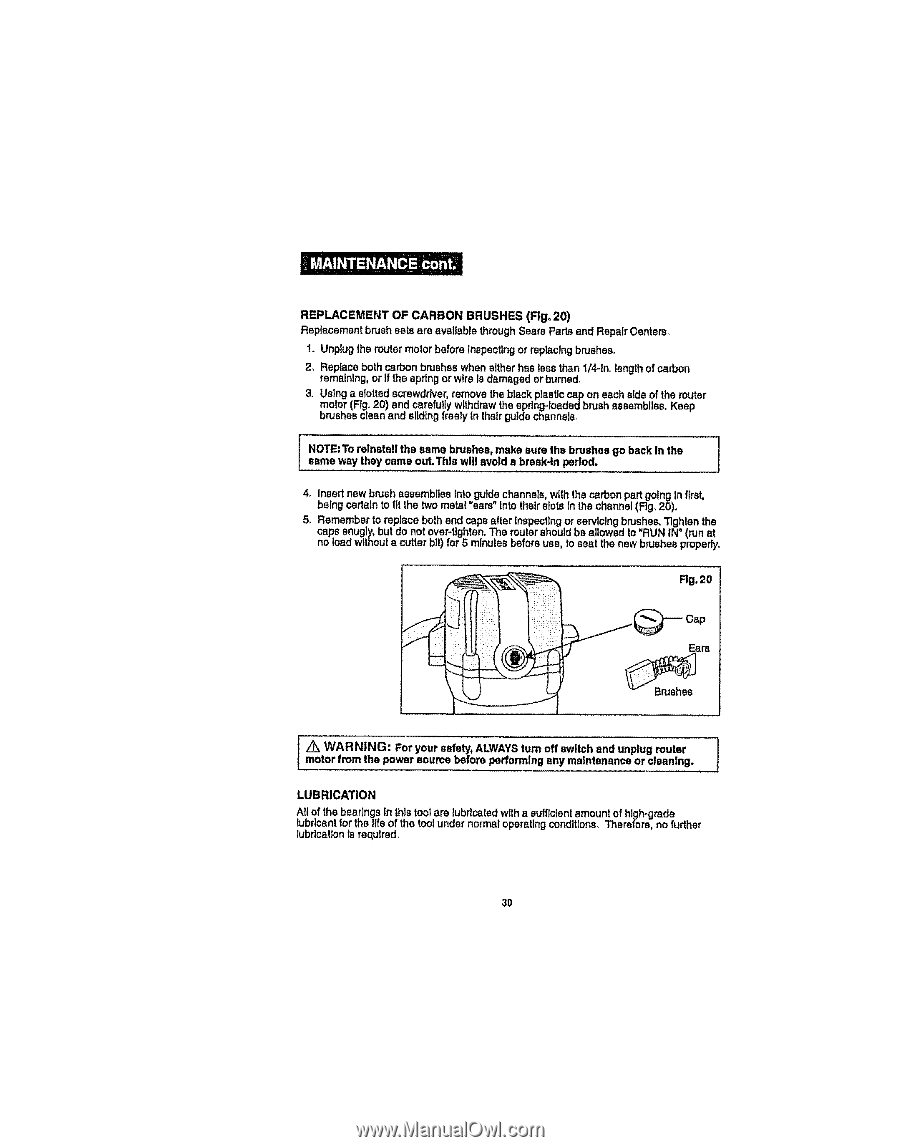

REPLACEMOEFNCTARBOBNRUSH(EFSlg2o0) Replacement brash sets am available throughSears Partsand Repair Centers. !. Unpiug the mulet motor before Inspecting or replacing brushes. 2. Replace both carbon brushes when either has less than 1/4-In. Iengthof carbon remaining,or If the springor wtra Is damaged or burned, 3. Usinga slotted screwdriver, remove the black ptastlccap on each side of the muter motor (Fig. 20) end carefullywithdrawthe spring=loaded brush assemblies. Keep brushes clean and elidingfraeIy tn their guide channais_ I NsaOmTeE;wTaoyrethinesytcaallmtheeosuatm.Tehisbruwsilhl easv,omidaakebsreuamk-tInhepebrr_uosdh,es go back In the 4, Insert new brush assembliesinto guide channels with the carbon partgoing In first, be ng cartaln to Ill the two metal "sam" Into their slots in the channel(Rg 20). 5. Remember to repiace both end caps after inspectingor servicing brushes. 11ghten the caps snugly, but do not over-tighten. The router should be allowed to "RUN IN" (tun at no lead withouta cutter blt) for 5 minutes befsre use, to seat the new brushes pioperfy. Fig. 20 I mZ_otoWrAfRroNmINtGh:e powFoer ysocuurmssafbeteyf,orAeLpWeArfYoSrmtuinrng osffayswmiatcinhteannadncuenpolurgclteaaunteinrg, LUBRICATION Atl of the bearings in thistoot are lubricatedwFthe suffletenl amount of high-grade lubricant forthe life of the tool under normaloperatingconditions,Therefore, no further lubdcatlon ts required 3O