Harbor Freight Tools 34706 User Manual - Page 12

Adjustments

|

View all Harbor Freight Tools 34706 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 12 highlights

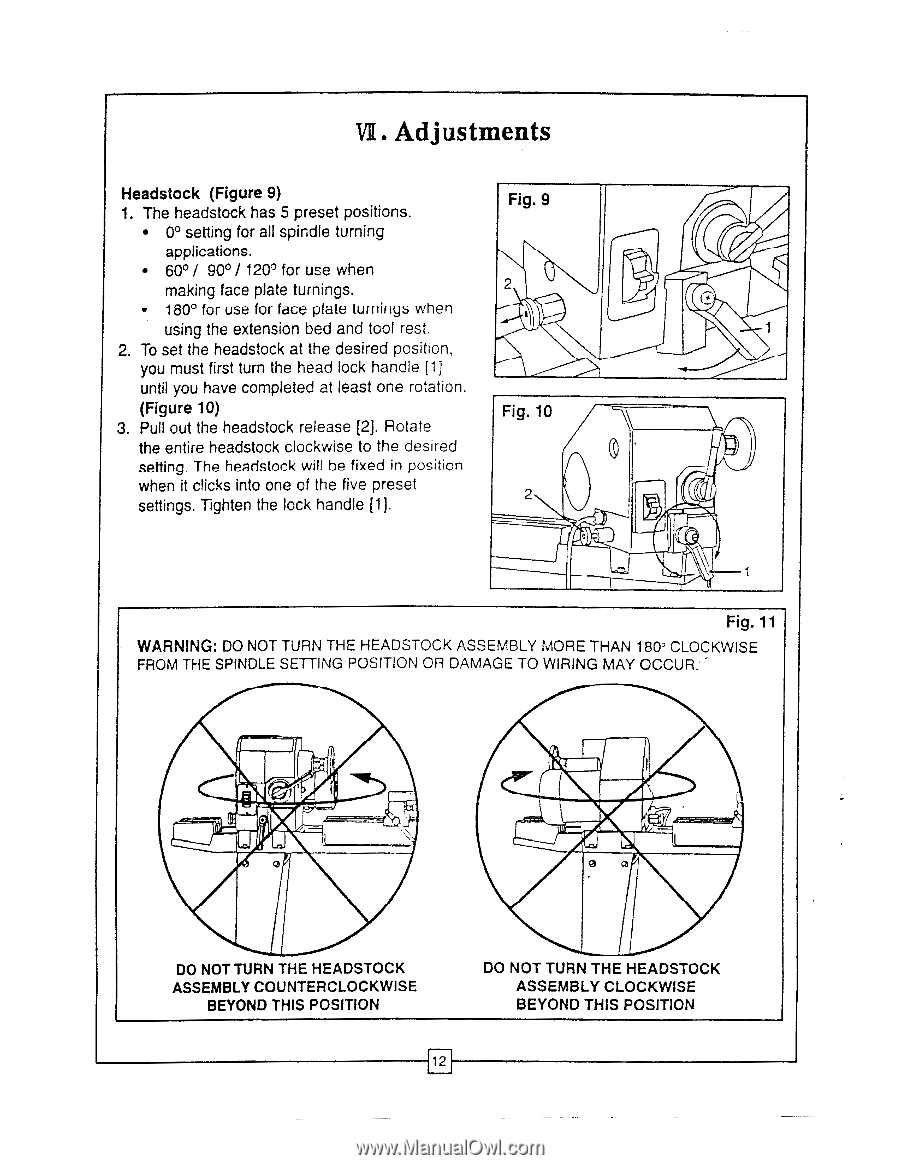

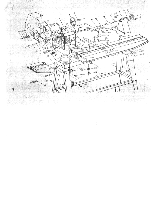

VIE. Adjustments Headstock (Figure 9) 1. The headstock has 5 preset positions. • 0° setting for all spindle turning applications. • 60° / 90° / 120° for use when making face plate turnings. • 180° for use for face plate turnings when using the extension bed and tool rest. 2. To set the headstock at the desired position, you must first turn the head lock handle [1] until you have completed at least one rotation. (Figure 10) 3. Pull out the headstock release [2]. Rotate the entire headstock clockwise to the desired setting. The headstock will be fixed in position when it clicks into one of the five preset settings. Tighten the lock handle [1]. Fig. 9 2 Fig. 10 2 oi Fig. 11 WARNING: DO NOT TURN THE HEADSTOCK ASSEMBLY MORE THAN 180° CLOCKWISE FROM THE SPINDLE SETTING POSITION OR DAMAGE TO WIRING MAY OCCUR. 0 a DO NOT TURN THE HEADSTOCK ASSEMBLY COUNTERCLOCKWISE BEYOND THIS POSITION DO NOT TURN THE HEADSTOCK ASSEMBLY CLOCKWISE BEYOND THIS POSITION 12