Harbor Freight Tools 34706 User Manual - Page 14

Operation, Maintenance

|

View all Harbor Freight Tools 34706 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 14 highlights

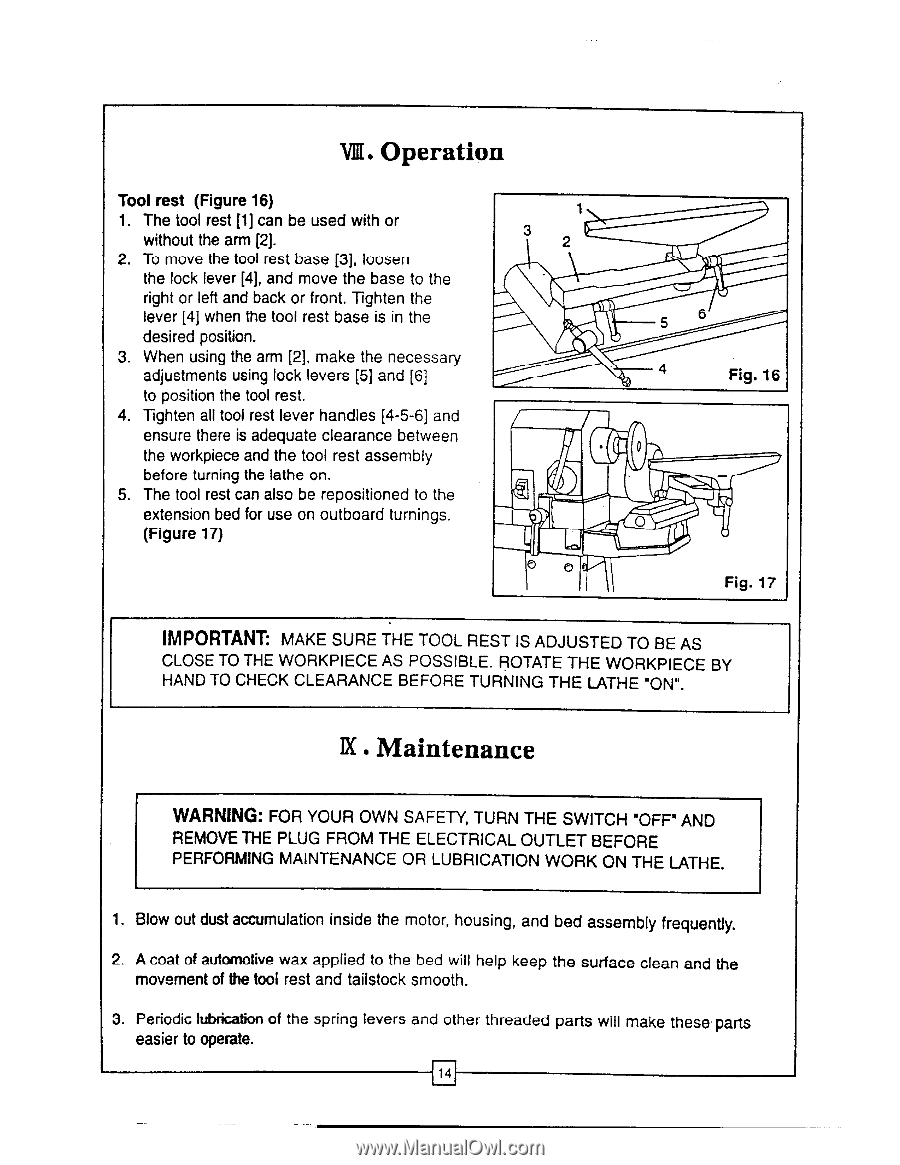

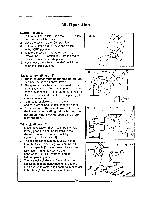

VI. Operation Tool rest (Figure 16) 1. The tool rest [1] can be used with or without the arm [2]. 2. To move the tool rest base [31, loosen the lock lever [4), and move the base to the right or left and back or front. Tighten the lever [4] when the tool rest base is in the desired position. 3. When using the arm [21, make the necessary adjustments using lock levers [6) and [6] to position the tool rest. 4. Tighten all tool rest lever handles [4-5-6] and ensure there is adequate clearance between the workpiece and the tool rest assembly before turning the lathe on. 5. The tool rest can also be repositioned to the extension bed for use on outboard turnings. (Figure 17) 3 2 I 5 6 4 Fig. 16 0 6 Fig. 17 IMPORTANT: MAKE SURE THE TOOL REST IS ADJUSTED TO BE AS CLOSE TO THE WORKPIECE AS POSSIBLE. ROTATE THE WORKPIECE BY HAND TO CHECK CLEARANCE BEFORE TURNING THE LATHE EON". DC . Maintenance WARNING: FOR YOUR OWN SAFETY, TURN THE SWITCH "OFF" AND REMOVE THE PLUG FROM THE ELECTRICAL OUTLET BEFORE PERFORMING MAINTENANCE OR LUBRICATION WORK ON THE LATHE. . Blow out dust accumulation inside the motor, housing, and bed assembly frequently. 2. A coat of automotive wax applied to the bed will help keep the surface clean and the movement of the tool rest and tailstock smooth. 3. Periodic lubrication of the spring levers and other threaded parts will make these parts easier to operate. 14