Hayward NorthStar All NorthStar models - Page 9

Storage/Winterization cont'd., ATTENTION, ATTENTION, WARNING, Shaft Seal Change Instructions - pump parts

|

View all Hayward NorthStar manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 9 highlights

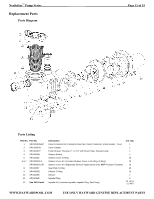

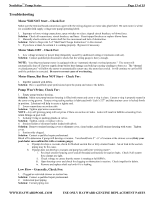

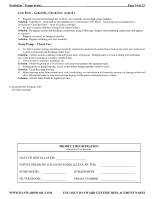

NorthStar™ Pump Series Page 9 of 15 Storage/Winterization (cont'd.) ATTENTION - Allowing the pump to freeze will void the warranty. ATTENTION - Use ONLY propylene glycol as antifreeze in your pool/spa system. Propylene glycol is non- toxic and will not damage plastic system components; other anti-freezes are highly toxic and may damage plastic components in the system. Drain all water from pump and piping when expecting freezing temperatures or when storing pump for a long time (see instructions below). Gravity drain system as far as possible. Keep motor dry and covered during storage. To avoid condensation/corrosion problems, do NOT cover or wrap pump with plastic film or bags. Storing Pump For Winterization WARNING - To avoid dangerous or fatal electrical shock hazard, turn OFF power to motor before draining pump. Failure to disconnect power may result in serious personal injury or death. 1. Drain water level below all inlets to the pool. 2. Remove drain plugs and strainer cover from strainer housing. (See Parts Diagram on page 11 of this manual for pump component locations.) 3. Disconnect pump from mounting pad, wiring (after power has been turned OFF), and piping. 4. Once the pump is fully drained, re-install the strainer cover and drain plugs. Store pump in a dry area. Shaft Seal Change Instructions IMPORTANT SAFETY INSTRUCTIONS PLEASE READ AND FOLLOW ALL INSTRUCTIONS When servicing electrical equipment, basic safety precautions should always be observed including the following. Failure to follow instructions may result in injury. A. Disconnect all electrical power service to pump before beginning shaft seal replacement. B. Only qualified personnel should attempt rotary seal replacement. Contact your local authorized Hayward Dealer or service center if you have any questions. Exercise extreme care in handling both the rotating and the stationary sections of the two-part replacement seal. Foreign matter or improper handling will easily scratch the graphite and ceramic sealing surfaces. Removing the Motor Assembly (See Parts Diagram on page 11 of this manual for pump component locations.) 1. Release motor lock ring latch (item #17), then grasp lock ring handle and rotate up. 2. Slide the motor assembly out of the pump/strainer housing (item #3), exposing the diffuser (item #10). Pull the diffuser off of the seal plate (item #14), exposing the impeller (item #12). (The diffuser may remain in the pump/strainer housing. To remove, pull it straight out of the pump/strainer housing.) Removing the Impeller (See Parts Diagram on page 11 of this manual for pump component locations.) 3. Remove the motor end cover by removing the two (2) screws or pry off the cap covering the motor shaft. Hex shaped caps must be twisted off. 4. To prevent motor shaft from turning, secure motor shaft using a 1/2" open-end wrench, which fits over the two (2) flats on the motor shaft. WWW.HAYWARDPOOL.COM USE ONLY HAYWARD GENUINE REPLACEMENT PARTS