HP Color LaserJet Pro M452 Print Media Guide - Page 22

Guidelines for using envelopes

|

View all HP Color LaserJet Pro M452 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 22 highlights

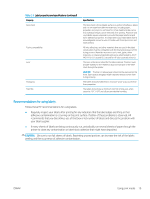

● Commercial or Official envelopes (also called Business or Regular), which have diagonal seams and standard gummed flaps, performed the most reliably. ● Envelopes that have double-sided seam construction, which creates vertical seams at both ends of the envelope instead of diagonal seams, tend to be more flimsy than diagonal-seam envelopes. Double-sided seam envelopes tend to jam or wrinkle unless the edges are thin and sharply creased. However, a variety of double-sided seam envelopes have performed acceptably during testing. ● Envelopes that have a peel-off adhesive strip or that have more than one flap that folds over for sealing, must use adhesives compatible with the heat and pressure of the printer's fusing process. Several varieties of this type of envelope performed satisfactorily in HP testing. However, the extra flaps and strips can result in increased jamming or wrinkling and poor toner adhesion due to the increased thickness of the envelope. ● Generally, feeding problems increase with envelope size. Larger envelope sizes (C5, B5) cannot have a basis weight greater than 105 g/m2 (28 lb). ● Rougher finishes such as laid, linen, or cockle can result in poor fusing. ● The multiple layers in envelopes construction might result in a noticeable background effect (small toner particles scattered in the non-imaged areas). You can reduce this effect by increasing the toner density setting on your printer. ● When running very large envelope jobs (several hundred to thousands), the fuser life might be reduced due to accelerated wear. ● The location of the envelope flap can cause feed problems. If the flap location is the same as the pick roller location (that is, the pick roller picks up the envelope by the flap), then the flap can move but the envelope cannot, causing a jam. In this situation, try rotating the envelope 180 degrees so you do not feed the envelop flap at the pick roller. Guidelines for using envelopes Follow these guidelines for using envelopes to ensure optimal performance. The envelope properties and specifications provided in this table generally apply to all HP LaserJet printers. See the support documentation that came with your printer for product-specific information. NOTE: For optimal results, print envelopes using the straightest paper path possible (for example, tray 1 to the face-up output bin). Table 2-2 Envelope properties and specifications Property Basis weight Caliper Surface roughness Specifications 60 g/m2 to 105 g/m2 (17 lb to 28 lb). See the support documentation that came with your printer for specific information. 0.09 mm to 0.14 mm (3.6 mil to 5.5 mil) for a single-layer thickness. 100 to 200 Sheffield. 16 Chapter 2 Guidelines for using print media ENWW