HP Designjet L25500 HP Designjet L25500 Printer Series - Maintenance and troub - Page 37

Avoiding substrate jams, The substrate is deformed or wrinkled, The automatic cutter does not work - vinyl printer

|

View all HP Designjet L25500 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 37 highlights

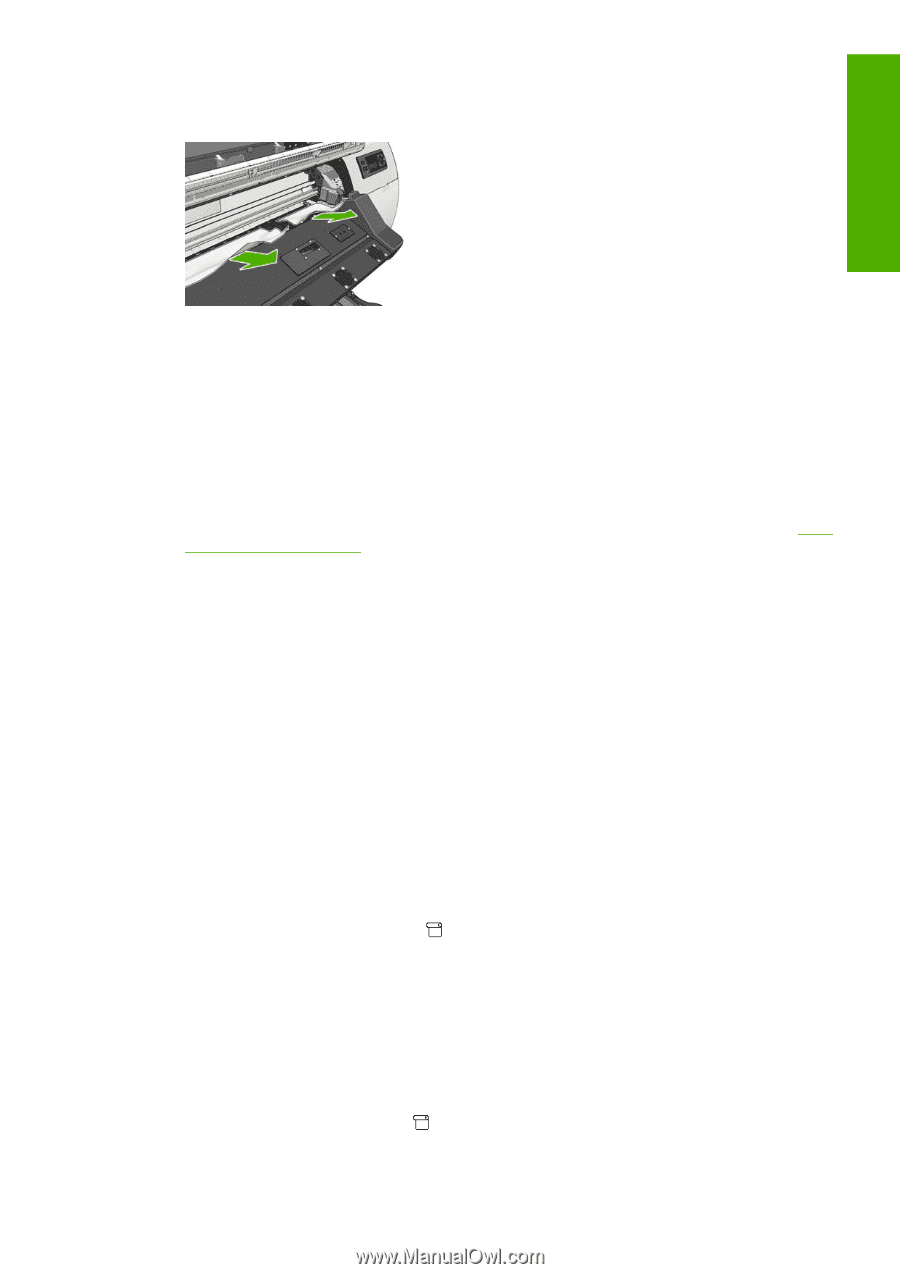

Troubleshoot substrate 5. Carefully remove any of the jammed substrate that you can lift up and out from the top of the printer. Cut the substrate if necessary. 6. Carefully pull the remainder of the roll down and out of the printer. 7. Lower the substrate-adjustment lever, check that there is no substrate left in the printer (especially not in the curing module), then close and lock the window. 8. Turn on the printer. 9. Reload the roll. 10. If some substrate continues to cause an obstruction within the printer, it can often be cleared by loading a rigid substrate type into the printer. 11. If you find that you have print-quality problems after a jam, try realigning the printheads. See Align the printheads on page 10. Avoiding substrate jams Substrate jams may be caused by loading the substrate with too much skew: do not ignore the warning message that appears during the loading process in this case. They may also be caused by not enough vacuum suction in the printing zone. If you decide to increase the suction, do not exceed the following limits: 20 mmH2O for banners, 35 mmH2O for vinyl, and 50 mmH2O for other substrate families. The substrate is deformed or wrinkled If your substrate is deformed or wrinkled by the drying and curing process, change the temperature settings before printing the next job, and advance the substrate, using the Move Substrate key on the front panel, so that the next job will be printed on undamaged substrate. If the problem appears only at the beginning of the print, try the following suggestions. ● Disable the automatic cutter. ● Go to the front panel and select the icon, then Substrate handling options > Extra bottom margin. Set the margin 100 mm. If that is not enough, try 200 mm. This extra margin will apply only to jobs that start printing when the printer is idle and when the cutter is disabled. ● Decrease the warm-up drying temperature in steps of 5°C, without reducing it below the drying temperature. The automatic cutter does not work The automatic cutter is disabled when the take-up reel is in use. To use the cutter, disable the take-up reel on the front panel by selecting the icon, then selecting Take-up reel > Disable take-up reel. ENWW The substrate is deformed or wrinkled 31