HP Integrity rx2620 Site Preparation Guide. First Edition - HP Integrity rx262 - Page 22

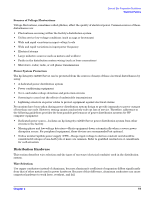

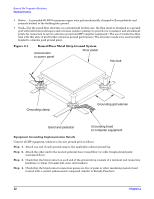

Raised Floor Metal Strip Ground System, Ground wire, to power panel, Floor panel, Hex bolt

|

View all HP Integrity rx2620 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 22 highlights

General Site Preparation Guidelines Electrical Factors • Better- A grounded #6 AWG minimum copper wire grid mechanically clamped to floor pedestals and properly bonded to the building/site ground. • Good-Use the raised floor structure as a ground grid. In this case, the floor must be designed as a ground grid with bolted down stringers and corrosion resistive plating (to provide low resistance and attachment points for connection to service entrance ground and HP computer equipment). The use of conductive floor tiles with this style of grid further enhances ground performance. The structure needs to be mechanically bonded to a known good ground point. Figure 2-1 Raised Floor Metal Strip Ground System Ground wire Floor panel to power panel Hex bolt Grounding clamp Grounding grid elemen Band and pedestal Grounding braid to computer equipment Equipment Grounding Implementation Details Connect all HP equipment cabinets to the site ground grid as follows: Step 1. Attach one end of each ground strap to the applicable cabinet ground lug. Step 2. Attach the other end to the nearest pedestal base (raised floor) or cable trough ground point (nonraised floor). Step 3. Check that the braid contact on each end of the ground strap consists of a terminal and connection hardware (a 1/4-in. [6.0-mm] bolt, nuts, and washers). Step 4. Check that the braid contact connection points are free of paint or other insulating material and treated with a contact enhancement compound (similar to Burndy Penetrox). 22 Chapter 2