HP LaserJet M9040/M9050 Service Manual - Page 167

Tray 4 pickup and feed, Tray 4 media level and media size detection, Tray 4 jam detection

|

View all HP LaserJet M9040/M9050 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 167 highlights

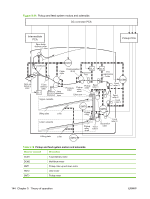

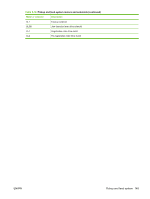

Tray 4 pickup and feed The formatter sends a signal to the driver PCA to start driving the pickup and feed motors. Rotated by the rollers, the pickup roller picks up a sheet, the separation roller removes any excessive sheets, and the feed roller transports the sheet to the registration roller unit. After the media enters the registration roller unit, the registration roller corrects the skew and the second feed roller feeds the media to the product. When the media reaches the merge-point in the product, the driver PCA checks for a merge-point permission command sent from the formatter. If the signal is detected, Tray 4 continues feeding to the product. If the signal is not detected, Tray 4 stops feeding until the signal is received. Tray 4 media level and media size detection The paper level is detected by the paper-level sensors (PS21 to 23) on the paper-level sensor PCA. The combination of these sensors determines the level of the print media loaded in Tray 4. The paper size is detected by the paper size detection switches (SW11 to 15) on the paper size detection switch PCA. The combination of these switches determines the paper size. Tray 4 sends the size and level information to the product formatter. Tray 4 jam detection Tray 4 determines a jam by monitoring the presence of media in the sensor areas at specific times that are stored in the CPU. If the CPU determines a jam under the following conditions, the tray stops feeding operations and notifies the formatter. Table 5-18 Tray 4 jam detection Jam type Description Residual jam The registration paper sensor (PS11) or jam sensor (PS103) detects media during the warm-up period. Pickup delay jam The between page sensor (PS12) does not detect media after receiving a print command or the PS12 sensor detects media, but the registration paper sensor (PS11) does not. Pickup stationary jam The edge does not clear the registration paper sensor (PS11) after the between-page sensor (PS12) detects the trailing edge of the media. Feed delay jam The jam sensor (PS103) does not detect media after the start of the registration rollers. Feed stationary jam The trailing edge of the media does not pass through the jam sensor (PS103) after the registration rollers are turned off. ENWW Tray 4 149