HP Scitex FB700 HP Scitex FB500 and FB700 Printer Series - Rigid Media Guide - Page 18

Glass - firmware

|

View all HP Scitex FB700 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 18 highlights

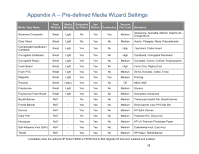

Glass Considerations The smooth, non-porous surface of glass does not provide a good interface for ink to adhere making it susceptible to scratches and scraping. Special precautions are necessary in the handling and display of the printed piece to protect it from abrasion. Adhesion can be improved with the use of a pre-treatment or primer, such as HP PT40 Specialty Glass Scitex Primer - part number CD571A. Preparation Use a lint-free cloth with a glass cleaner to remove dust or debris. Do not use a detergent. Use clean, cotton gloves to avoid fingerprints. If a pre-treatment primer is used, apply it according to the instructions and allow it to dry before printing. Recommended print modes Photo or Photo Plus modes for applications where it will be viewed from the printed surface. Use Max DPI - Saturated if higher ink density is needed. Indoor Signage Plus or higher quality for applications where it will be viewed through the glass and either a white ink overflood is used or white backer is applied over the printed surface. Flip the image in the RIP software prior to printing for view-through applications. Max DPI - Backlit, using either Spot or Overflood modes, for backlit applications. Printing Select Clear Sheet when configuring and loading this media. Media placement detection is disabled when using this media type. When loading the media, it is necessary to enter the location of the left (user side) and right (service side) edges of the media according to the Media Measurement Option selection. Use a Clear Sheet media profile from the RIP software. For applications that require fine detail, use the Fine Text option (available in firmware version 2.01 and later) and/or lower the printhead height from its nominal 0.085 inch (2.2 mm) setting. Output handling Use clean, cotton gloves to avoid fingerprints. Take care when loading or lifting sheets off the table as media and ink can be easily scratched. Depending on the end use application, a post treatment may be necessary to minimize risk of surface damage. 18