Hitachi NR90AF Instruction Manual - Page 15

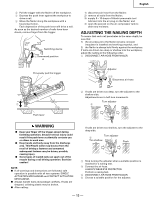

Warning, Adjusting The Nailing Depth

|

UPC - 717709012875

View all Hitachi NR90AF manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 15 highlights

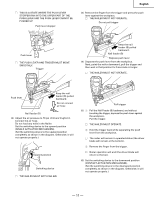

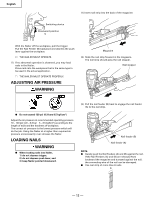

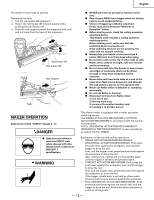

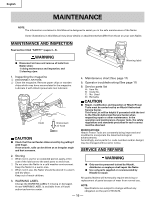

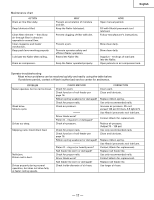

2 Pull the trigger with the Nailer off the workpiece. 3 Depress the push lever against the workpiece to drive a nail. 4 Move the Nailer along the workpiece with a bouncing motion. Each depression of the push lever will drive a nail. As soon as the desired number of nails have been driven, remove finger from the trigger. Switching device 1 Downward position English 1) disconnect air hose from the Nailer; 2) remove all nails from the Nailer; 3) supply 5 - 10 drops of Hitachi pneumatic tool lubricant into the air plug on the Nailer; and 4) open the petcock on the air compressor tank to drain any moisture. ADJUSTING THE NAILING DEPTH To assure that each nail penetrates to the same depth, be sure that: 1) the air pressure to the Nailer remains constant (requlator is installed and working properly), and 2) the Nailer is always held firmly against the workpiece. If nails are driven too deep or shallow into the workpiece, adjust the nailing in the following order. 1 DISCONNECT AIR HOSE FROM NAILER. Previously pull the trigger Adjuster 15 Disconnect air hose 2 4 Push lever 2 If nails are driven too deep, turn the adjuster to the shallow side. Adjustments are in half-turn increments. Turn adjuster 2 Too deep Flush WARNING ⅷ Keep your finger off the trigger except during fastening operation, because serious injury could result if the push lever accidentally contacts you or others in work area. ⅷ Keep hands and body away from the discharge area. This Hitachi nailer may bounce from the recoil of driving a fastener and unwanted subsequent fastener may be driven, possibly causing injury. ⅷ Some types of loaded nails can spark out of the muzzle during a nail driving operation. Exericise caution! NOTE: ⅷ If all warnings and instructions are followed, safe operation is possible with all two systems: SINGLE ACTUATION MECHANISM and CONTACT ACTUATION MECHANISM. ⅷ Always handle nails and package carefully. If nails are dropped, collating plastic may be broken. ⅷ After nailing: If nails are driven too shallow, turn the adjuster to the deep side. Turn adjuster 2 Too shallow Flush 3 Stop turning the adjuster when a suitable position is reached for a nailing test. 4 Connect the air hose. ALWAYS WEAR EYE PROTECTOR. Perform a nailing test. 5 DISCONNECT AIR HOSE FROM NAILER. 6 Choose a suitable position for the adjuster. - 15 -