Honeywell HW7500E Service Manual - Page 34

Electrical Diagnostics, HW3000/L Models, 120V Circuit #1 Check, No Output OR, Voltage Out of Spec - specs

|

UPC - 894190002049

View all Honeywell HW7500E manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 34 highlights

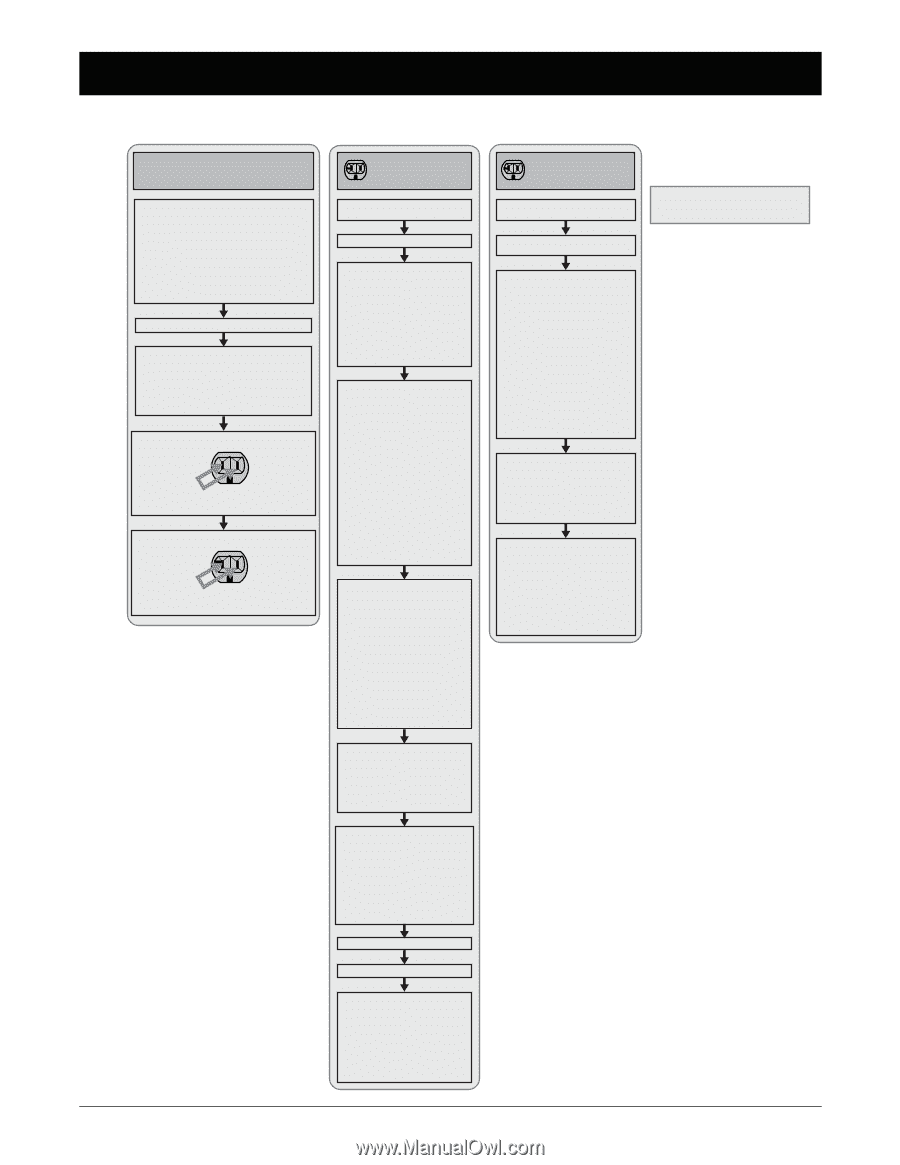

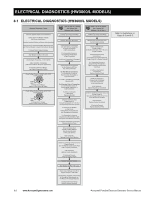

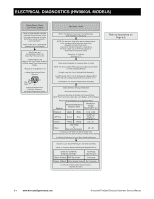

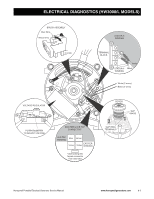

ELECTRICAL DIAGNOSTICS (HW3000/L MODELS) 8.1 ELECTRICAL DIAGNOSTICS (HW3000/L MODELS) General Electrical Check Check for Tripped Duplex Circuit Breaker(s) Outlets Above the Breaker Indicate the Excess Load Source Resolve Overload Problem to Ensure Safe Operation After Electrical Load Resolved Wait Several Minutes (for Thermal Breaker to Cool) Push to Reset Breaker If Cannot Reset, Replace Breaker Start Engine and Run at No Load Check Engine Frequency = 61.5 to 63 Hz Adjust Governor, if necessary (see Manual Section "Governor Adjustment") If Frequency Still Out of Range, see Engine Diagnostics Section Check Voltage Output at NEMA 5-20R 120V Duplex Outlet #1 W X 123- 126V G If Voltage Out of Range, Perform "120V Circuit #1 Check" Check Voltage Output at NEMA 5-20R 120V Duplex Outlet #2 W Y 123- 126V G If Voltage Out of Range, Perform "120V Circuit #2 Check" 120V Circuit #1 Check (No Output OR Voltage Out of Spec) Conduct This Check Only When Directed by General Electrical Check Remove Alternator End Cover Check Wires and Connections from AVR to Brush Assembly for Proper Orientation of Wire Connections If a Connection is Loose or Disconnected, Reestablish a Tight Connection If a Wire or Connection is Damaged, Replace AVR Check Wires and Connections for the Exciter & AVR Tap from AVR to Alternator On AVR Side of Connection: If a Connection is Loose or Disconnected, Reestablish a Tight Connection If a Wire or Connector is Damaged, Replace AVR On Alternator Side of Connection: If a Connection is Loose or Disconnected, Reestablish a Tight Connection If a Wire or Connector is Damaged, Replace Alternator Check for Continuity from Duplex Outlet #1 for Each Connection (X, Y, W, G) to Corresponding Alternator Terminal If Continuity Not Present in Any Circuit, Check Wires and Connections from Receptacle to Alternator If a Connection is Loose or Disconnected, Reestablish a Tight Connection and Recheck Continuity If a Wire or Connection is Damaged, Replace Electrical Panel 120V Circuit #2 Check (No Output OR Voltage Out of Spec) Conduct This Check Only When Directed by General Electrical Check Remove Main Control Panel from Control Panel Assembly Check Continuity from Duplex Outlet #1 for Each Connection (X or Y, W, G) to Duplex Outlet #2 If Continuity Not Present in Any Circuit, Check Wires and Connections from Duplex Outlet #1 to Duplex Outlet #2 If a Connection is Loose or Disconnected, Reestablish a Tight Connection and Recheck Continuity If a Wire or Connection is Damaged, Replace Electrical Panel Check for Continuity in Duplex Outlet #2 Breaker from the Line Terminal to the Load Terminal If No Continuity, Replace Duplex Circuit Breaker Check for Continuity in Each Circuit of Duplex Outlet #2 from the Female Socket on the Front to the Terminal on the Back If No Continuity, Replace Duplex Receptacle If Continuity Present, Replace Electrical Panel Check for Continuity in Duplex Outlet #1 Breaker from the Line Terminal to the Load Terminal If No Continuity, Replace Duplex Circuit Breaker Check for Continuity in Each Circuit of Duplex Outlet #1 from the Female Socket on the Front to the Terminal on the Back If No Continuity, Replace Duplex Receptacle If Continuity Present, Replace Electrical Panel Perform "Alternator Check" Start Engine and Run at No Load Check Output Voltage (X to W) of Duplex Outlet #1= 123-126V Adjust Voltage Regulator, if Necessary by Turning the Potentiometer on the Rear of the Voltage Regulator If Voltage Still Out of Range Replace Voltage Regulator Refer to Illustrations on Pages 8-3 and 8-5. 8-2 www.honeywellgenerators.com Honeywell Portable Electrical Generator Service Manual