Kenmore 32956 Owners Manual - Page 10

Toprotect, against, untimelycorrosionof

|

View all Kenmore 32956 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 10 highlights

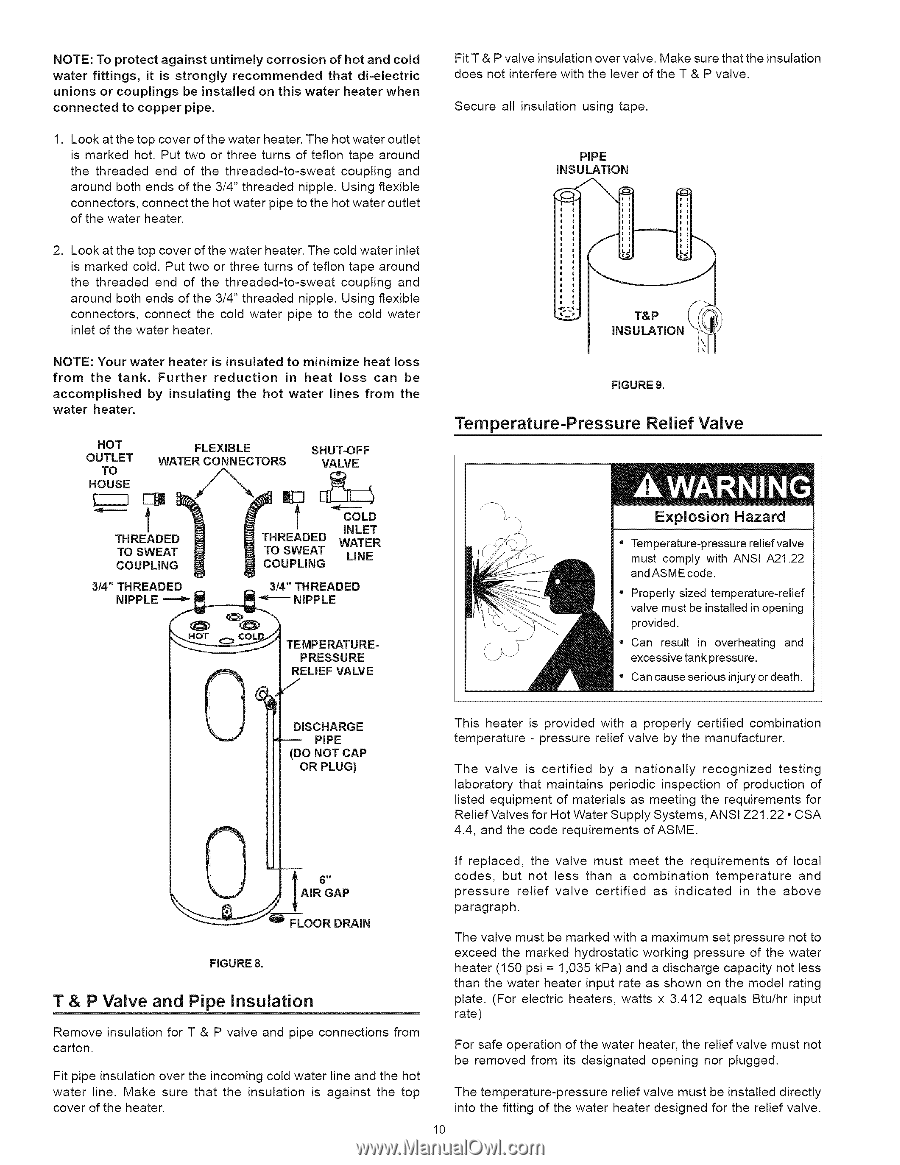

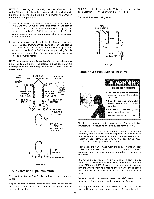

NOTET:oprotecatgainsutntimelycorrosionofhot and cold water fittings, it is strongly recommended that di=electric unions or couplings be installed on this water heater when connected to copper pipe. 1. Look at the top cover of the water heater. The hot water outlet is marked hot. Put two or three turns of teflon tape around the threaded end of the threaded-to-sweat coupling and around both ends of the 3/4" threaded nipple. Using flexible connectors, connect the hot water pipe to the hot water outlet of the water heater. 2. Look at the top cover of the water heater. The cold water inlet is marked cold. Put two or three turns of teflon tape around the threaded end of the threaded-to-sweat coupling and around both ends of the 3/4" threaded nipple. Using flexible connectors, connect the cold water pipe to the cold water inlet of the water heater. NOTE: Your water heater is insulated to minimize heat loss from the tank, Further reduction in heat loss can be accomplished water heater, by insulating the hot water lines from the HOT OUTLET TO FLEXIBLE WATER CONNECTORS SHUT-OFF VALVE HOUSE l THREADED TO SWEAT COUPLING 3/4" THREADED [_ THREADED TO SWEAT COUPLING CINOLLEDT WATER LINE - 3!4" THREADED NIPPLE HOT _ COL NIPPLE TEMPERATUREPRESSURE Fit T & P valve insulation over valve. Make sure that the insulation does not interfere with the lever of the T & P valve. Secure all insulation using tape. PIPE INSULATION :'= T&P ('_ iNSULATION "_\_/_ FIGU RE 9. Temperature-Pressure Relief Valve Explosion Hazard / •Tem perature-pressure relief valve must comply with ANSI A21.22 andASMEcode. " Properly sized temperature-relief valve must be installed in opening provided. • Can result in overheating and excessive tank pressure. , Can cause serious injury or death. RDEISLCIEHFARVGAELVE -- PIPE (DO NOT CAP OR PLUG) This heater is provided with a properly certified combination temperature - pressure relief valve by the manufacturer. The valve is certified by a nationally recognized testing laboratory that maintains periodic inspection of production of listed equipment of materials as meeting the requirements for Relief Valves for Hot Water Supply Systems, ANSI Z21.22 • CSA 4.4, and the code requirements of ASME. 6" FLOOR DRAIN FIGURE 8. T & P Valve and Pipe Insulation Remove insulation for T & P valve and pipe connections carton. from Fit pipe insulation over the incoming cold water line and the hot water line. Make sure that the insulation is against the top cover of the heater. If replaced, the valve must meet the requirements of local codes, but not less than a combination temperature and pressure relief valve certified as indicated in the above paragraph. The valve must be marked with a maximum set pressure not to exceed the marked hydrostatic working pressure of the water heater (150 psi = 1,035 kPa) and a discharge capacity not less than the water heater input rate as shown on the model rating plate. (For electric heaters, watts x 3.412 equals Btu/hr input rate) For safe operation of the water heater, the relief valve must not be removed from its designated opening nor plugged. The temperature-pressure relief valve must be installed directly into the fitting of the water heater designed for the relief valve. 10