Kenmore 8804 Installation Instructions - Page 4

Supply, Requirements - parts

|

View all Kenmore 8804 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 4 highlights

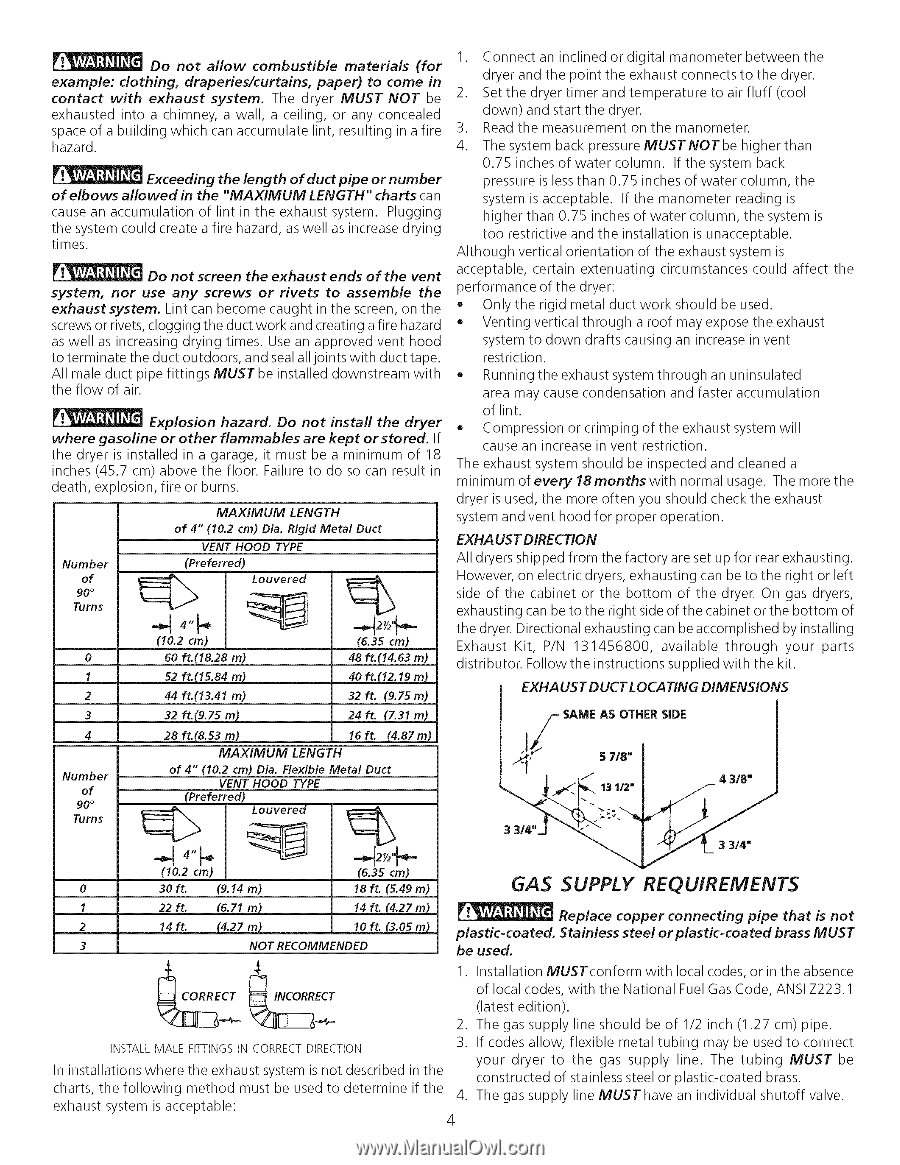

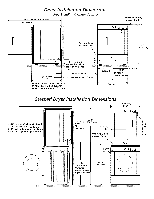

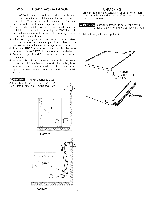

Do not allow combustible materials (for example: clothing, draperies/curtains, paper) to come in contact with exhaust system. The dryer MUST NOT be exhausted into a chimney, a wall, a ceiling, or any concealed space of a building which can accumulate lint, resulting in a fire hazard. Exceeding the length of duct pipe or number of elbows allowed in the "MAXIMUM LENGTH" charts can cause an accumulation of lint in the exhaust system. Plugging the system could create a fire hazard, as well as increase drying times. Do not screen the exhaust ends of the vent system, nor use any screws or rivets to assemble the exhaust system. Lint can become caught in the screen, on the screws or rivets, clogging the duct work and creating a fire hazard as well as increasing drying times. Use an approved vent hood to terminate the duct outdoors, and seal all joints with duct tape. All male duct pipe fittings MUSTbe installed downstream with the flow of air. Explosion hazard. Do not install the dryer where gasoline or other flammables are kept or stored. If the dryer is installed in a garage, it must be a minimum of 18 inches (45.7 cm) above the floor. Failure to do so can result in death, explosion, fire or burns. Number of 90 ° Turns MAXIMUM LENGTH of 4" 110.2 cm) Dia. Rigid Metal VENT HOOD TYPE (Preferred) Duct Louvered 0 1 2 3 4 Number of 90 ° Turns (10.2 cm) 60 ft.(18.28 m) 52ft.(IS.84m) 44 ft.113.41 m) 32 ft.(9.zsm) 2 _/2'_. (6.35 cm) 48 ft.114.63 m) 40 ft.(12.19 In) 32ft. 19.75m) 24ft. {7.31m) 28 ft.(8.53 m) MAXIMUM 16ft. (4.87m) LENGTH of 4" (10.2 cm) Dia. Flexible Metal Duct VENT HOOD TYPE (Preferred) I. Connect an inclined or digital manometer between the dryer and the point the exhaust connects to the dryer. 2. Set the dryer timer and temperature to air fluff (cool down) and start the dryer. 3. Read the measurement on the manometer. 4. The system back pressure MUSTNOT be higher than 0.75 inches of water column. If the system back pressure is lessthan 0.75 inches of water column, the system is acceptable. If the manometer reading is higher than 0.75 inches of water column, the system is too restrictive and the installation is unacceptable. Although vertical orientation of the exhaust system is acceptable, certain extenuating circumstances could affect the performance of the dryer: • Only the rigid metal duct work should be used. • Venting vertical through a roof may expose the exhaust system to down drafts causing an increase in vent restriction. • Running the exhaust system through an uninsulated area may cause condensation and faster accumulation of lint. • Compression or crimping of the exhaust system will cause an increase in vent restriction. The exhaust system should be inspected and cleaned a minimum of every 18months with normal usage. The more the dryer is used, the more often you should check the exhaust system and vent hood for proper operation. EXHAUST DIRECTION All dryers shipped from the factory are set up for rear exhausting. However, on electric dryers, exhausting can be to the right or left side of the cabinet or the bottom of the dryer. On gas dryers, exhausting can be to the right side of the cabinet or the bottom of the dryer. Directional exhausting can be accomplished by installing Exhaust Kit, P/N 131456800, available through your parts distributor. Follow the instructions supplied with the kit. EXHAUST DUCT LOCATING DIMENSIONS I/ I _'}_ k. SAME AS OTHER SIDE ./" 5 718" /_,31=j (10.2 cm) 0 3Oft. (9.14 m) (6.35 cm) 18 ft. (5.49 m) GAS SUPPLY REQUIREMENTS 1 22 ft. (6.71 m} 14 ft. (4.27 m) Replace copper connecting pipe that is not 2 14 ft. (4.27 m) 10 ft. (3.05 m) plastic-coated. Stainless steel or plastic-coated brass MUST 3 NOT RECOMMENDED be used. I. Installation MUSTconform with local codes, or in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1 (latest edition). 2. The gas supply line should be of 1/2 inch (1.27 cm) pipe. INSTALML ALEFITTINGISN CORRECDTIRECTION 3. If codes allow, flexible metal tubing may be used to connect your dryer to the gas supply line. The tubing MUST be In installations where the exhaust system is not described in the constructed of stainless steel or plastic-coated brass. charts, the following method must be used to determine if the 4. The gas supply line MUSThave an individual shutoff valve. exhaust system is acceptable: 4