Lexmark MC2325 Paper and Specialty Media Guide PDF - Page 17

Coatings, Offset powders, Envelopes, Envelope guidelines

|

View all Lexmark MC2325 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 17 highlights

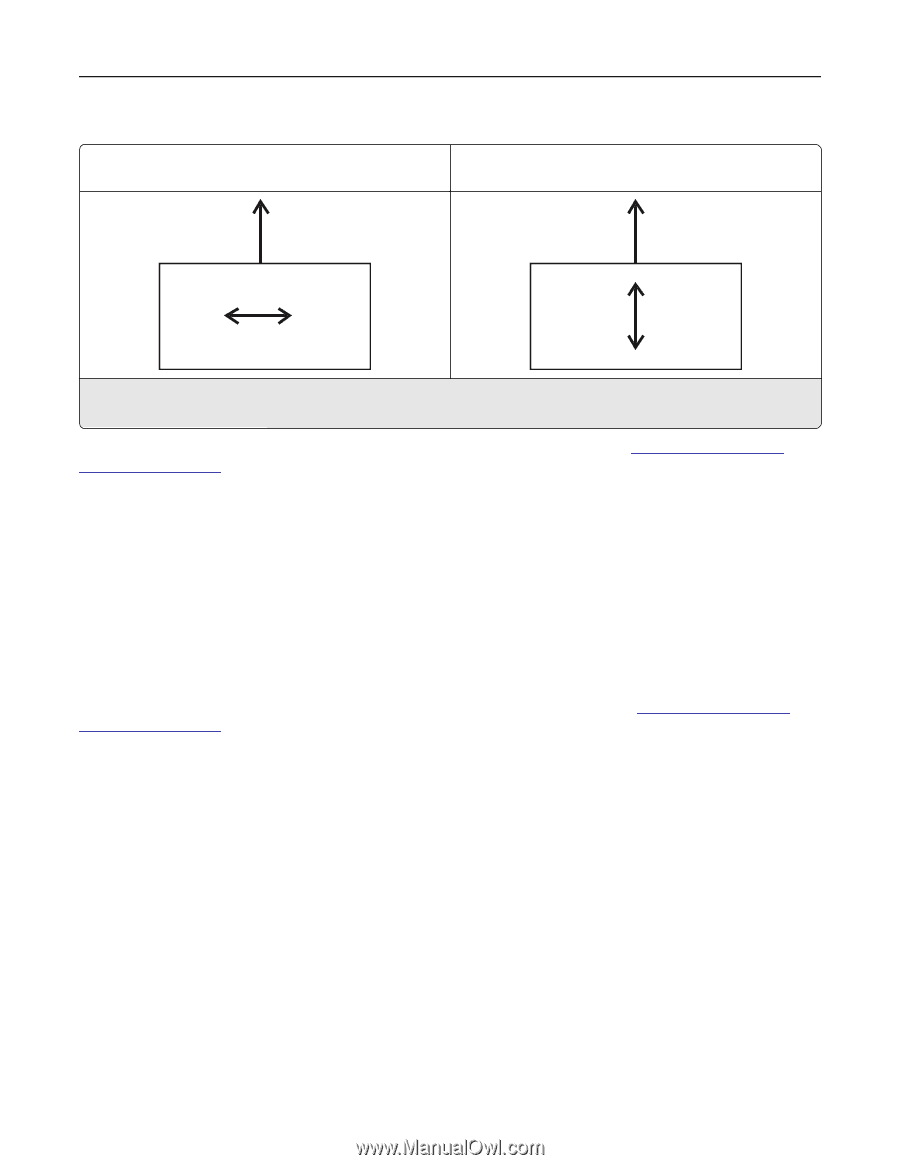

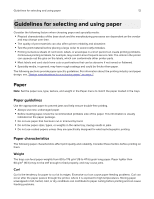

Guidelines for selecting and using paper 17 For materials fed long edge first Grain long is recommended for stock heavier than 135 g/m2. A Grain short is recommended for stock lighter than 135 g/m2. A B B A Feed direction B Grain direction For more information about the recommended grain direction for card stock, see "Printer-specific paper support" on page 30. Coatings Surface texture and coatings on card stock significantly affect toner adhesion (fuse grade), print quality, and feed reliability. We recommend a vellum finish for the best printing performance. We do not recommend glossy coatings and slick surfaces or surfaces that mimic laid finishes (glossy paper, not glossy card stock, is acceptable for some printers). Paper smoothness also affects print quality. If the paper is too rough, the toner does not fuse to the paper properly. If the paper is too smooth, it can affect feed reliability. We recommend smoothness to be from 50 to 300 Sheffield points (50 Sheffield is optimal) for color laser printers. For mono laser printers, we recommend 150-250 Sheffield points. Using media higher than 300 Sheffield could result in printing degradation. For more information about the individual printer Sheffield recommendations, see "Printer-specific paper support" on page 30. Offset powders We do not recommend using offset powders or other foreign materials to speed drying. Offset powders are used by print shops to prevent printed pages from sticking together. Powder is usually sprayed on the printed page right before it reaches the stacker on the offset printing press. This powder provides an intermediate layer between two sheets of paper, preventing ink from transferring from one sheet to another. Envelopes Envelope guidelines • Set the paper size, type, texture, and weight in the Paper menu to match the envelopes loaded in the tray. • Print samples on the envelopes being considered for use before buying large quantities. • Use envelopes designed specifically for laser printers. • For best performance, use envelopes made from 90 g/m2 (24‑lb) paper or 25 percent cotton.