Lexmark MC2325 Paper and Specialty Media Guide PDF - Page 23

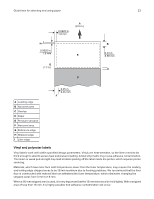

Vinyl and polyester labels, BA CB EC FD DE GF HG IH AI

|

View all Lexmark MC2325 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 23 highlights

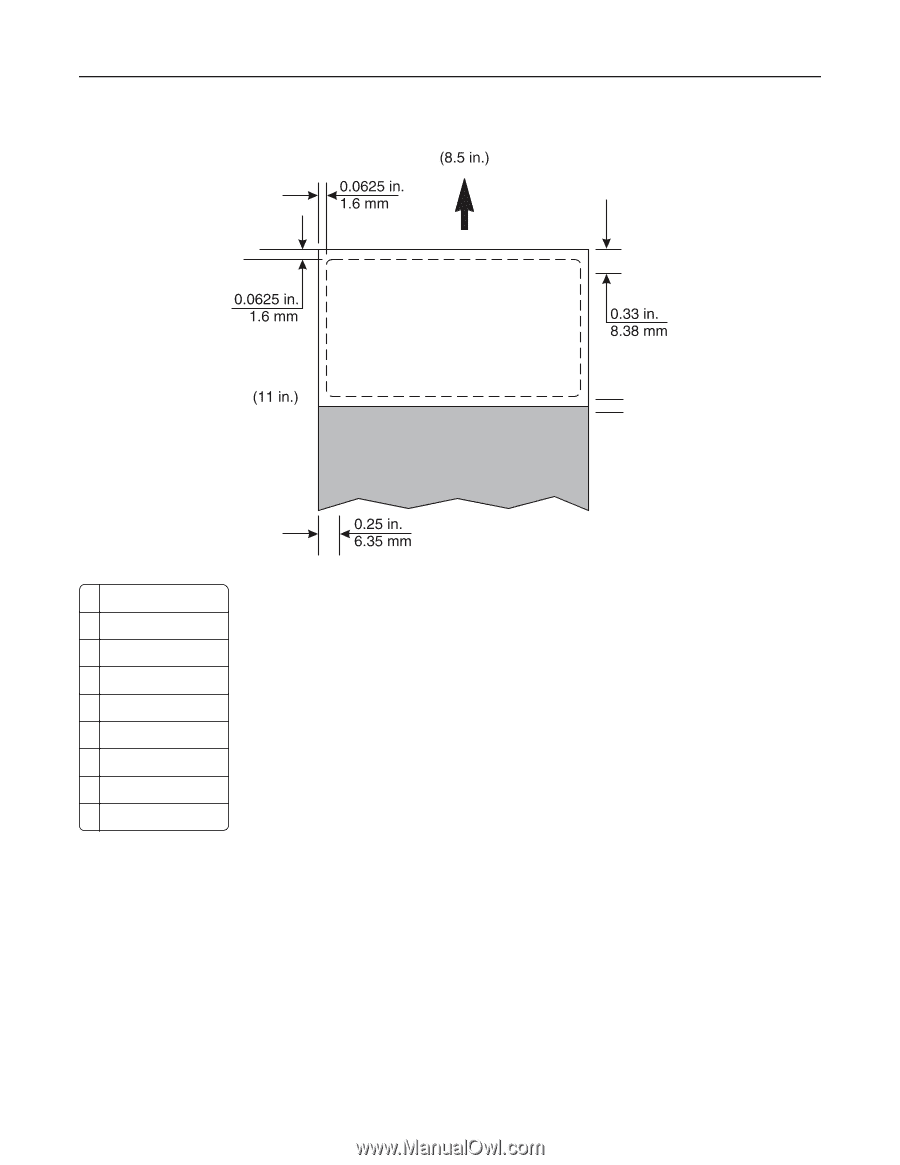

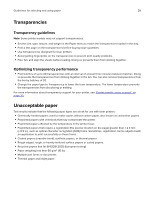

Guidelines for selecting and using paper 23 A HI B E G C D F A Leading edge B Non‑print area C Overlay D Paper E Pressure‑sensitive F Non‑print area G Reference edge H Stripped edge I Liner edge Vinyl and polyester labels Vinyl labels work well within specified design parameters. Vinyls are heat‑sensitive, so the liners need to be thick enough to absorb excess heat and prevent melting. A total strip matrix may cause adhesive contamination. Thin liners or weak pull strength may lead to labels peeling off the label inside the printer, which requires printer servicing. Materials, which have liner face melt temperatures lower than the fuser temperature, may require the leading and trailing edge stripped areas to be 1.6 mm maximum due to feeding problems. We recommend that the liner face is constructed with material that can withstand the fuser temperature, which eliminates changing the stripped areas from 3 mm to 1.6 mm. When a 1.6‑mm stripped area is used, it is very important that the 1.6‑mm tolerance be held tightly. With a stripped area of less than 1.6 mm, it is highly possible that adhesive contamination will occur.