Metabo WEF 15-150 Quick Operating Instructions - Page 17

Cleaning, Troubleshooting

|

View all Metabo WEF 15-150 Quick manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 17 highlights

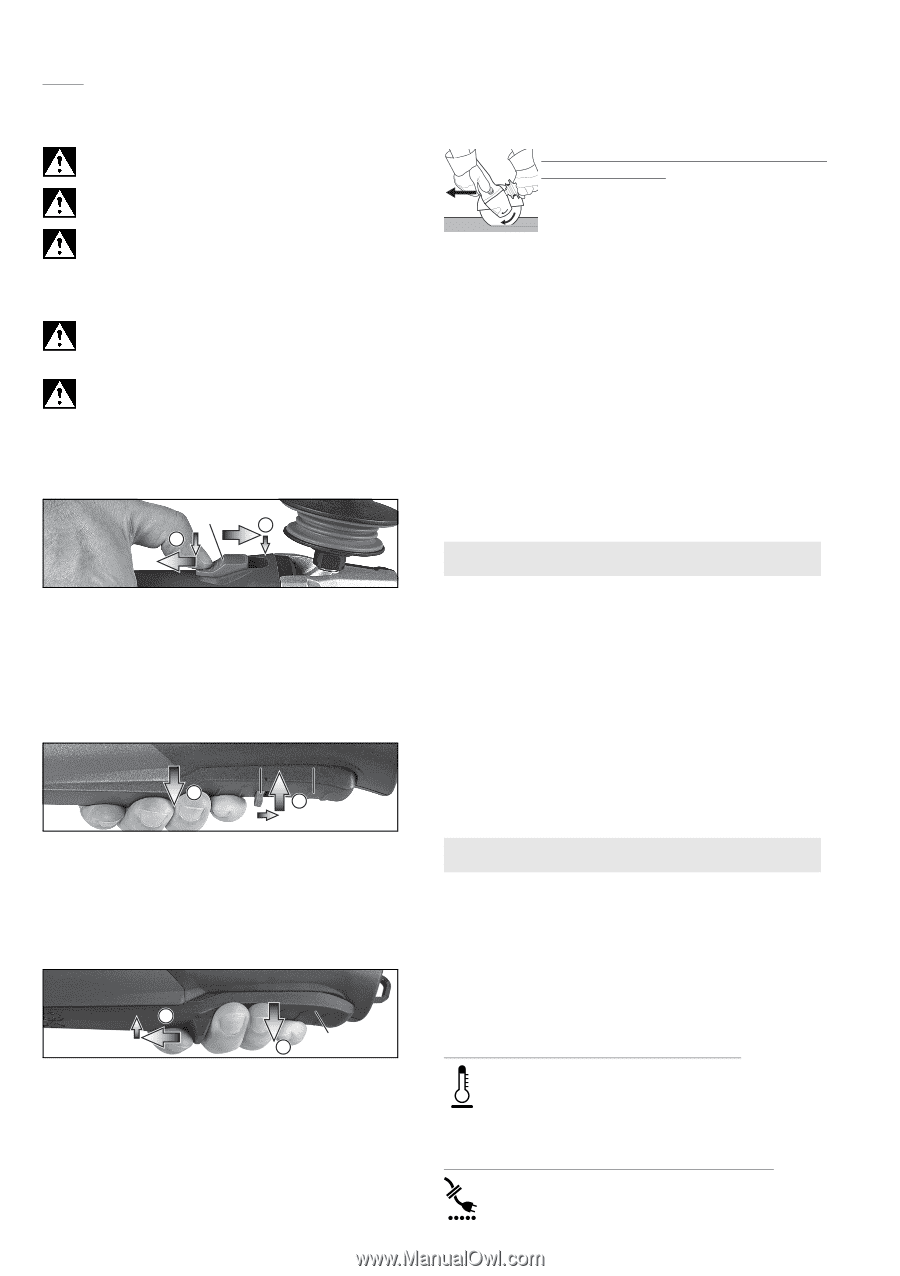

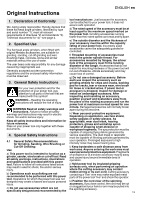

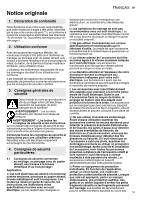

Note: We recommend using our angle polisher for polishing work. 8.2 Switching On and Off Always guide the machine with both hands. Switch on first, then guide the accessory towards the workpiece. The machine must not be allowed to draw in additional dust and shavings. When switching the machine on and off, keep it away from dust deposits. After switching off the machine, only place it down when the motor has come to a standstill. Avoid inadvertent starts: always switch the tool off when the plug is removed from the mains socket or if there has been a power cut. In continuous operation, the machine continues running if it is forced out of your hands. Therefore, always hold the machine with both hands using the handles provided, stand securely and concentrate. Machines with slide switch: 8 ENGLISH en workpiece does not become too hot. Rough grinding: position the machine at an angle of 30° - 40° for the best working results. Cut-off grinding: Always work against the run of the disc (see illustration). Otherwise there is the danger of the machine kicking back from the cut out of control. Guide the machine evenly at a speed suitable for the material being processed. Do not tilt, apply excessive force or sway from side to side. Wire brushing: Press down the machine evenly. 8.4 Rotate gear housing See illustration D on page 3. - Disconnect the mains plug. - Remove guard (6). - Unscrew the 4 gear housing screws (a). CAUTION! Do not remove the gear housing! - Turn the gear housing to the desired position without removing it. - Screw in the 4 gear housing screws (a) in the available threads! Tightening torque = 3,0 Nm +/0,3 Nm. 0 I 9. Cleaning Switching on: Push the sliding switch (8) forward. For continuous activation, now tilt downwards until it engages. Switching off: Press the rear end of the sliding switch (8) and release the sliding switch. WEPF 15-150 Quick: "Paddle switch" (with dead man's function): 12 13 0 I It is possible that particles deposit inside the power tool during operation. This impairs the cooling of the power tool. Conductive build-up can impair the protective insulation of the power tool and cause electrical hazards. The power tool should be cleaned regularly, often and thoroughly through all front and rear air vents using a vacuum cleaner or by blowing in dry air. Prior to this operation, separate the power tool from the power source and wear protective glasses and dust mask. Regularly clean dust filter: remove and blow out with compressed air. Switching on: Slide the switch-on lock (12) in the direction of the arrow and press the trigger 10. Troubleshooting switch (13). Switching off: Release the trigger switch (13). WEPBF 15-150 Quick: "Paddle switch" (with dead man's function): I 0 1130 - Electronic safety shutdown The electronic signal display (10) flashes and the machine was automatically SWITCHED OFF. If the slew rate of the current is too high (for example, if the machine suddenly seizes or kickback occurs), the machine switches off. Switch machine off with switch. Switch it on again and continue to work as normal. Try to prevent the machine from seizing. See chapter 4.2. Machines with VTC and TC electronics: Switching on: Slide the trigger switch (13) in the direction of the arrow and press the trigger switch (13). Switching off: Release the trigger switch (13). The electronic signal display (10) lights up and the load speed decreases. There is too much load on the machine! Run the machine in idling until the electronics signal indicator switches off. 8.3 Working Directions Machines with VTC, TC and VC electronics: Grinding and sanding operations: Press down the machine evenly on the surface and move back and forth so that the surface of the The electronic signal display (10) flashes and the machine does not start. The restart protection is active. If the mains plug is 17