Poulan 1992-05 User Manual - Page 16

Guide, Chain

|

View all Poulan 1992-05 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 16 highlights

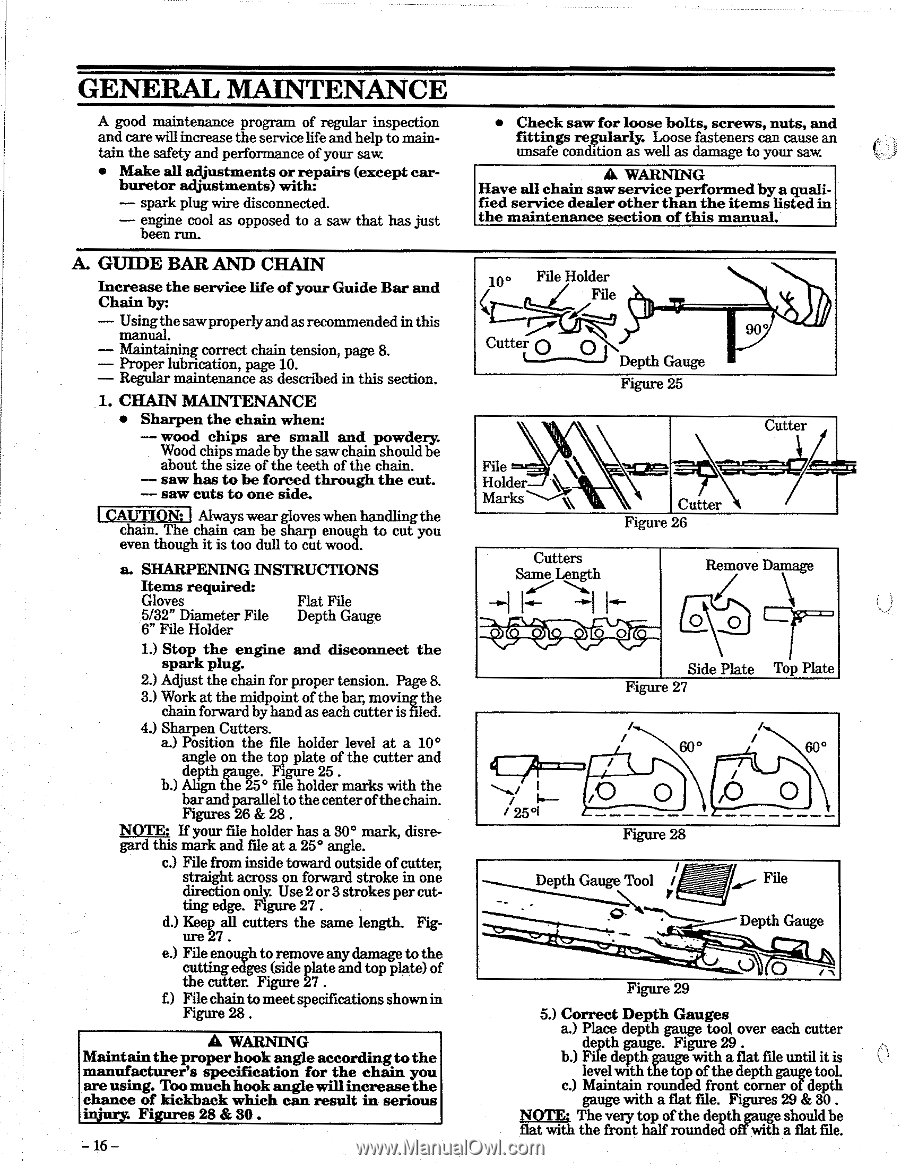

GENERAL MAINTENANCE A good maintenance program of regular inspection and care will increase the service life and help to maintain the safety and performance of your saw. • Make all adjustments or repairs (except carburetor adjustments) with: - spark plug wire disconnected. - engine cool as opposed to a saw that has just been run. A. GUIDE BAR. AND CHAIN Increase the service life of your Guide Bar and Chain by: - Using the saw properly and as recommended in this manual. - Maintaining coned. chain tension, page 8. - Proper lubrication, page 10. - Regular maintenance as described in this section. 1. CHAIN MAINTENANCE • Sharpen the chain when: -- wood chips are small and powdery. Wood chips made by the saw chain should be about the size of the teeth of the chain. -- saw has to be forced through the cut. -- saw cuts to one side. CAUTION: Always wear gloves when handlingthe chain. The chain can be sharp eno to cut you even though it is too dull to cut woo a. SHARPENING INSTRUCTIONS Items require& Gloves 5/32" Diameter File 6" File Holder Flat File Depth Gauge 1.) Stop the engine and disconnect the spark plug. 2.) Adjust the chain for proper tension. Page 8. 3.) Work at the midpoint of the bar, moving the chain forward by hand as each cutter is filed. 4.) Sharpen Cutters. a.) Position the file holder level at a 10° angle on the top plate of the cutter and depth gauge. Figure 25. b.) Align the 25° file holder marks with the bar and parallel to the center of the chain. Figures 26 & 28 . NOTE: If your file holder has a 30° mark, disregard this mark and file at a 25° angle. c.) File from inside toward outside of cutter, straight across on forward stroke in one direction only. Use 2 or3strokes per cutting edge. Figure 27 . d.) Keep all cutters the same length. Figure 27 . e.) File enough to remove any damage to the cutting edges (side plate and top plate) of the cutter. Figure 27 . £) File chain to meet specifications shown in Figure 28 . A WARNING Maintain the proper hook angle according to the manufacturer's specification for the chain you are using. Too much hook angle will increase the chance of kickback which can result in serious injury. Figures 28 & 30 . - 16 - • Check saw for loose bolts, screws, nuts, and fittings regularly. Loose fasteners can cause an unsafe condition as well as damage to your saw. A WARNING Have all chain saw service performed by a qualified service dealer other than the items listed in the maintenance section of this manual. 10° File Holder File 90° Cutter O O Depth Gauge Figure 25 4utter File Holder Marks Cutter Figure 26 Cutters Same Length Remove Damage H 0 Side Plate Top Plate Figure 27 ,O O 25°I Figure 28 Depth Gauge Tool /II O File Depth Gauge Figure 29 0 0 5.) Correct Depth Gauges a.) Place depth gauge tool over each cutter depth gauge. Figure 29 . b.) File depth gauge with a flat file until it is level with the top of the depth gauge tool. c.) Maintain rounded front corner of depth gauge with a. flat file. Figures 29 & 30 . NOTE: The very top of the depth gauge should be flat with the front half rounded off with a flat file.