Rheem Versa Heaters Operating Instructions - Page 14

Internal Automatic Bypass Valve, External Auxiliary Bypass Valve, Pressure Relief Valve Installation

|

View all Rheem Versa Heaters manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 14 highlights

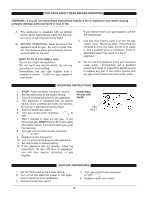

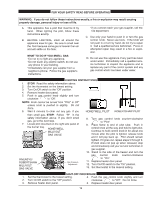

High-temperature CPVC header flanges and header flange nuts are available as an option. If there is any possibility of back-siphoning when the pump stops, it is recommended that a check valve (or valves) also be installed in the system. Internal Automatic Bypass Valve A built-in automatic bypass valve is provided in the In/Out header. The internal bypass valve automatically responds to changes in water pressure in the piping system. The proper amount of water flow is maintained through the heater under varying pressures dictated by the conditions of the pump and filter. From Heater To Heater Full Port Ball Valve or Globe Valve To Pool/Spa Bypass Valve From Pool/Spa Fig. 15: Auxiliary Bypass Valve Bypass Disc NOTE: Do not use a gate valve as an auxiliary bypass valve. Spring Bypass Body Auxiliary Bypass Valve Adjustment To set bypass: With clean filter, adjustment is made by feeling the inlet and outlet pipes at the heater. Outlet pipes should be slightly warmer than inlet and comfortable to the touch. If pipe is hot, close bypass; if cold, open bypass. Pressure Relief Valve Installation Fig. 14: Internal Automatic Bypass Valve External Auxiliary Bypass Valve An auxiliary bypass valve must be used when flow rates exceed 70 GPM. Usually a high-performance pump size larger than one horsepower will exceed this flow rate. This valve is required to complement the function of the automatic bypass valve, particularly when starting the heater in winter or early spring when the spa or pool temperature is below 50°F. It also serves to eliminate needless pressure drop through the heater and accompanying reduction in the flow rate to the spa jets, etc. To conform to local building codes, it may be necessary to install a pressure relief valve. A 3/4" pressure relief valve, having a capacity equal to the BTUH output of the heater to be installed, is recommended for this heater. The maximum pressure relief valve setting is 125 psi. This relief valve needs to be installed on the outlet pipe from the header as noted in Fig. 16 below. Pipe onto Discharge Side of Piping Fig. 16: Pressure Relief Valve Installed 14