Ridgid K-75 Owners Manual - Page 7

Machine Inspection - k 75b

|

View all Ridgid K-75 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 7 highlights

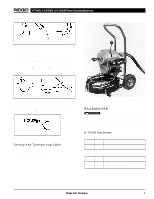

K-75A/B, K-1500A/B, & K-1500SP Drain Cleaning Machines Clutch Handle Tool Guide Hose are present, do not use the Drain Cleaning Machine until any problem has been repaired. Clutch Handle Tool Guide Hose FOR/OFF/REV Switch FOR/OFF/REV Switch Figure 1 - K-75A, K-1500A and K-1500SPA Drain Cleaners Machine Inspection WARNING To prevent serious injury, inspect your Drain Cleaning Machine. The following inspection procedures should be performed before each use. 1. Make sure the Drain Cleaning Machine is unplugged and the directional switch is set to the OFF position (Figures 1 and 2). 2. Inspect the power cord, Ground Fault Circuit Interrupter (GFCI) and plug for damage. If the plug has been modified, is missing the grounding prong or if the cord is damaged, do not use the Drain Cleaning Machine until the cord has been replaced. 3. Inspect the Drain Cleaning Machine for any broken, missing, misaligned or binding parts as well as any other conditions which may affect the safe and normal operation of the machine. If any of these conditions Figure 2 - K-75B, K-1500B and K-1500SP Drain Cleaning Machines 4. Lubricate the Drain Cleaning Machine, if necessary, according to the Maintenance Instructions. 5. Use tools and accessories that are designed for your drain cleaner and meet the needs of your application. The correct tools and accessories allow you to do the job successfully and safely. Accessories suitable for use with other equipment may be hazardous when used with this drain cleaner. 6. Clean any oil, grease or dirt from all equipment handles and controls. This reduces the risk of injury due to a tool or control slipping from your grip. 7. Inspect the cutting edges of your tools. If necessary, have them sharpened or replaced prior to using the Drain Cleaning Machine. Dull or damaged cutting tools can lead to binding and cable breakage. 8. Inspect cables and couplings for wear and damage. Cables should be replaced when they become severely worn or corroded. A worn cable can be identified when the outside coils become flat. WARNING Worn or damaged cables can break causing serious injury. Ridge Tool Company 5