Ridgid RP 200-B User Manual - Page 6

Description, Specifications, And Standard Equipment, Specific Safety Information - press

|

View all Ridgid RP 200-B manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 6 highlights

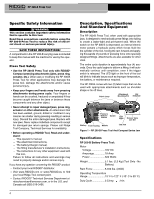

RP 200-B Press Tool Specific Safety Information WARNING This section contains important safety information that is specific to this tool. Read these precautions carefully before using the RP 200-B Press Tool to reduce the risk of electrical shock or serious personal injury. SAVE THESE INSTRUCTIONS! A compartment in the RP 200-B carrying case is included to keep this manual with the machine for use by the operator. Press Tool Safety • Use the RP 200-B Press Tool only with RIDGID® Compact pressing attachments (jaws, press ring, actuator, etc.). Other uses or modifying the RP 200-B Press Tool for other applications may damage the press tool, damage the attachments and/or cause personal injury. • Keep your fingers and hands away from pressing attachments during press cycle. Your fingers or hands can be crushed, fractured or amputated if they become caught between the jaws or between these components and any other object. • Never attempt to repair damaged jaws, press ring, actuator or other attachments. An attachment that has been welded, ground, drilled or modified in any manner can shatter during pressing resulting in serious injury. Discard the entire damaged jaws. Replace with new jaws. Never replace individual components except for damaged jaw return springs. Please call Ridge Tool Company, Technical Services for availability. • Before operating a RIDGID Tool, Read and understand: - This operator's manual, - The attachment instructions, - The battery/charger manual, - The fitting manufacturer's installation instructions, - The instructions for any other equipment used with this tool, Failure to follow all instructions and warnings may result in property damage and/or serious injury. If you have any question concerning this RIDGID® product: - Contact your local RIDGID® distributor. - Visit www.RIDGID.com or www.RIDGID.eu to find your local Ridge Tool contact point. - Contact RIDGID® Technical Services Department at [email protected], or in the U.S. and Canada call (800) 519-3456. 4 Description, Specifications And Standard Equipment Description The RP 200-B Press Tool, when used with appropriate jaws, is designed to mechanically press fittings onto tubing to create a water-tight and permanent seal. When the switch on the RP 200-B is depressed, an internal electric motor powers a hydraulic pump which forces fluid into the cylinder of the tool, forcing the ram forward and applying thousands of pounds of pressing force onto specially designed fittings. Attachments are also available for other uses. The entire cycle duration is approximately four (4) seconds. Once the cycle begins to deform a fitting, it will automatically continue until completion, even if the trigger switch is released. The LED light on the front of the tool will blink to indicate issues such as improper temperature, low battery, or maintenance required. The RP 200-B comes with two (2) fabric loops that can be used with appropriate attachments such as shoulder straps or tie off lines. Fabric Loop Attachment Mounting Pin Jaw Sideplate Pressure Release Switch Button LED Light Scissor Style Jaw Set Battery Tool Housing Handle Jaw Arm Figure 1 - RP 200-B Press Tool And Compact Series Jaw Specifications RP 200-B Battery Press Tool: Motor Voltage 18V DC Amperage 18 Amp Power 324 Watts Weight 5.1 lbs. (2,3 Kg) (Tool Only - No Battery) Ram Force 5,400 lbs. (24kN) Operating Temperature Range 15° F to 122° F (-10° C to 50° C) Duty Cycle 3 Crimp /min.