Stihl FS 100 RX Product Instruction Manual - Page 27

Operating Instructions, Cleaning the Air Filter, Engine Management - replacement parts

|

View all Stihl FS 100 RX manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 27 highlights

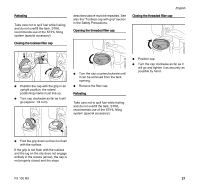

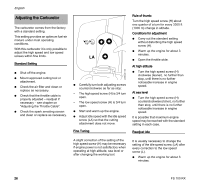

English Operating Instructions Cleaning the Air Filter Engine Management During break-in period A factory-new machine should not be run at high revs (full throttle off load) for the first three tank fillings. This avoids unnecessary high loads during the break-in period. As all moving parts have to bed in during the break-in period, the frictional resistances in the engine are greater during this period. The engine develops its maximum power after about 5 to 15 tank fillings. During Operation After a long period of full throttle operation, allow the engine to run for a short while at idle speed so that engine heat can be dissipated by the flow of cooling air. This protects enginemounted components (ignition, carburetor) from thermal overload. After Finishing Work Storing for a short period: Wait for the engine to cool down. Empty the fuel tank and keep the machine in a dry place, well away from sources of ignition, until you need it again. For longer out-ofservice periods - see "Storing the Machine". If there is a noticeable loss of engine power 4 1 2 N Turn the choke knob to g N Take out the screw (1) and remove the filter cover (2). N Clean away loose dirt from around the filter. N Grip the filter element (3) at the cutout (arrow) in the filter housing (4) and remove it. N Fit a new filter element. As a temporary measure you can knock it out on the palm of your hand or blow it out with compressed air. Do not wash. N Replace damaged parts. Installing the filter N Install the filter element in the filter housing and fit the cover. N Insert the screw and tighten it down firmly. 273BA006 KN Exhaust emissions are controlled by the design of the fundamental engine parameters and components (e.g. carburation, ignition, timing and valve or port timing) without the addition of any major hardware. FS 100 RX 25