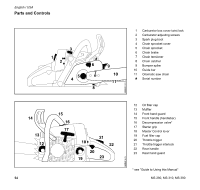

Stihl MS 290 STIHL FARM BOSS Product Instruction Manual - Page 52

Sharpening Tools special accessories

|

View all Stihl MS 290 STIHL FARM BOSS manuals

Add to My Manuals

Save this manual to your list of manuals |

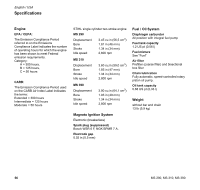

Page 52 highlights

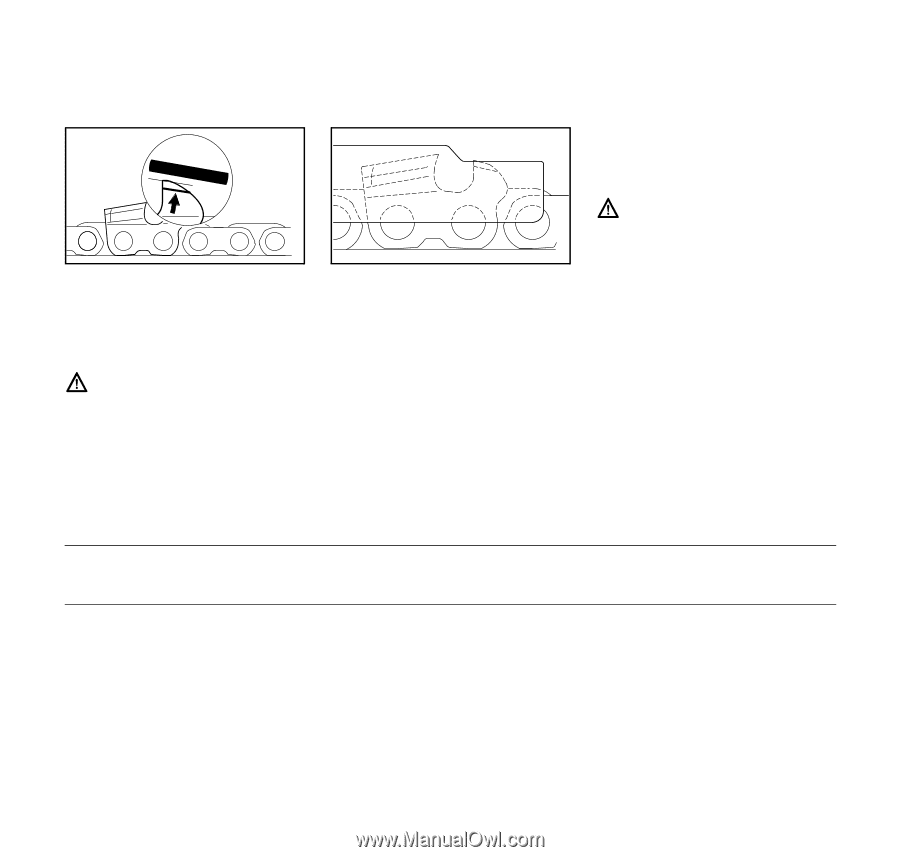

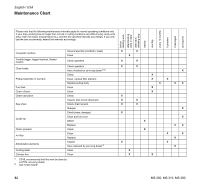

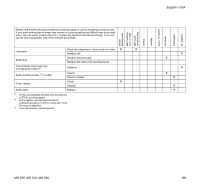

English / USA : File the top of the depth gauge parallel to the stamped service marking (see arrow) - but do not lower the highest point of the depth gauge in this process. The kickback tendency of the chainsaw is increased if the depth gauges are too low. 689BA044 KN 689BA052 KN : Place filing gauge on the chain - highest point of depth gauge must be level with the filing gauge. PM 1, RM2: Rear hump of tie strap (with service marking) is lowered along with the depth gauge. RSC3, RMC3, PMC3, PMMC3: The upper part of the humped drive link (with service marking) is lowered along with the depth gauge. The other parts of the triple-humped tie strap and humped drive link must not be filed since this may increase the kickback tendency of the chainsaw. : After sharpening, clean the chain thoroughly, remove filings or grinding dust - lubricate the chain thoroughly. : Before long out-of-service period, clean the chain and store it in a well-oiled condition. Sharpening Tools (special accessories) Chain pitch Round file Ø Round file inch 1/4 3/8 PMN 3/8 P 0.325 3/8 0.404 (mm) mm (inch) (6.35) 4.0 (9.32) 4.0 (9.32) 4.0 (8.25) 4.8 (9.32) 5.2 (10.26) 5.5 (5/32) (5/32) (5/32) (3/16) (13/64) (7/32) Part No. 5605 772 4006 5605 772 4006 5605 772 4006 5605 772 4806 5605 772 5206 5605 772 5506 File holder Part No. 5605 750 4327 5605 750 4327 5605 750 4327 5605 750 4328 5605 750 4329 5605 750 4330 Filing gauge Part No. 1110 893 4000 0000 893 4000 1110 893 4000 1110 893 4000 1110 893 4000 1106 893 4000 Flat file1) Part No. 0814 252 3356 0814 252 3356 0814 252 3356 0814 252 3356 0814 252 3356 0814 252 3356 Sharpening kit2) Part No. 5605 007 1027 5605 007 1026 5605 007 1027 5605 007 1028 5605 007 1029 5605 007 1030 1) Use triangular file 0811 421 8971 for PM1 and RM2 2) consisting of file holder with round file, flat file and filing gauge MS 290, MS 310, MS 390 51