Viking QSC200SS Installation Instructions - Page 7

Caution

|

View all Viking QSC200SS manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 7 highlights

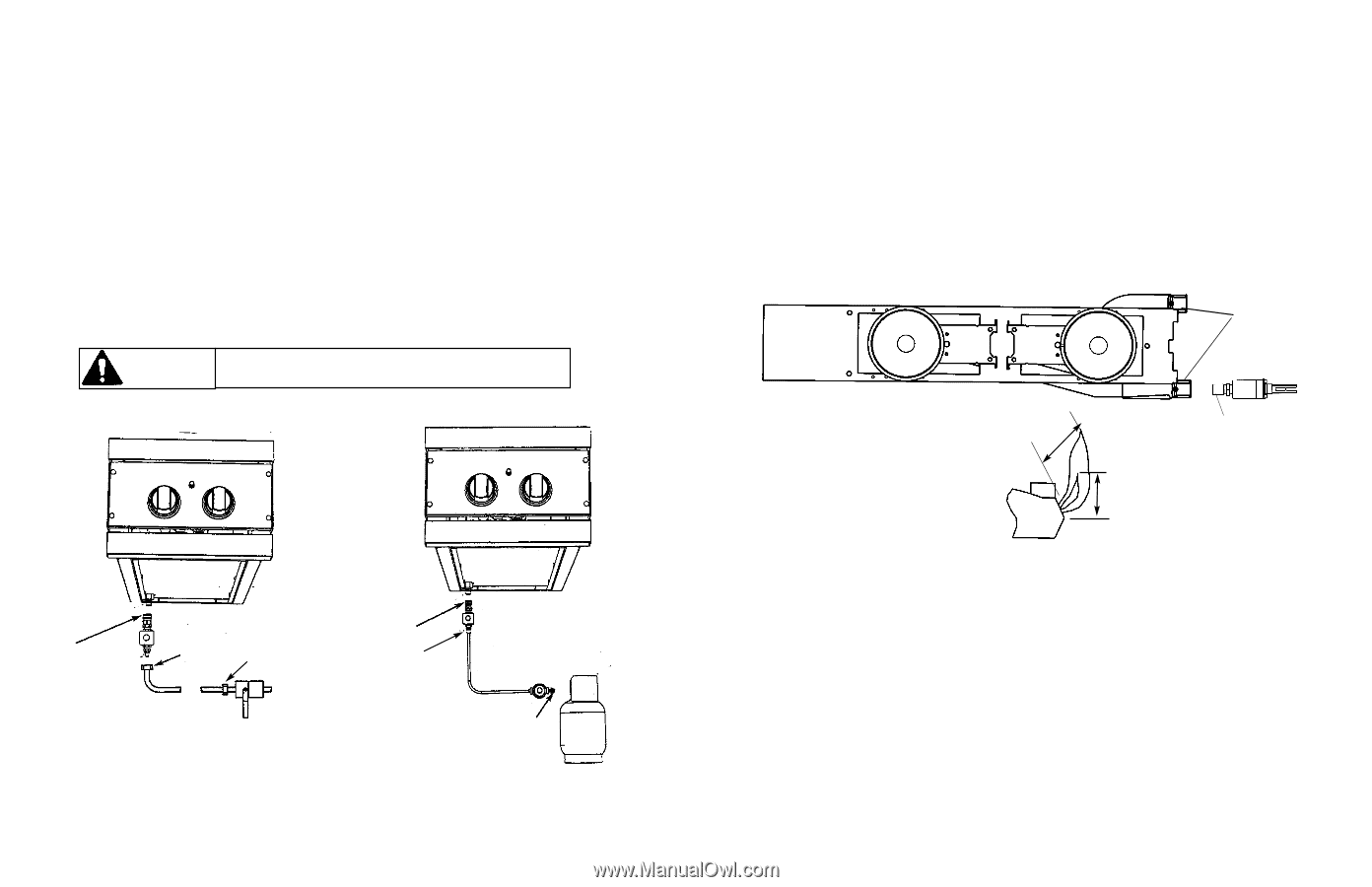

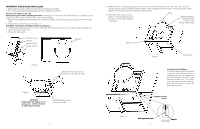

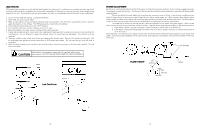

LEAK TESTING Although all gas connections on the grill are leak tested at the factory prior to shipment, a complete gas tightness check must be performed at the installation due to possible mishandling in shipment or excessive pressure unknowingly being applied to the unit. Periodically check the whole system for leaks, or immediately check if the smell of gas is detected. 1. Do not smoke while leak testing. Extinguish all flames. 2. Never leak test with an open flame. 3. Make a soap solution of one part liquid detergent and one part water. You will need a spray bottle, brush or towel to apply the solution to the fittings. For LP/Propane units, check with a full cylinder. 4. Check that all control knobs are in the "OFF" position. 5. Turn cylinder valve knob counter clockwise one turn to open. 6. Blowing bubbles in the soap solution indicates that a leak is present. 7. Stop a leak by tightening the loose joint or by replacing the faulty part with a replacement part recommended by the manufacturer. Do not attempt to repair the cylinder valve if it should become damaged. The cylinder must be replaced. 8. If you are unable to stop a leak, shut off the gas supply at the cylinder valve. Remove the cylinder from the grill. Call an authorized gas appliance service technician or LP/Propane gas dealer. Do not use the grill until the leak is corrected. 9. After checking for leaks, push in and turn any control knob to release the pressure in the hose and manifold. Turn off the control knob. Before placing into operation, always check for gas leaks with a soapy CAUTION water solution. DO NOT USE AN OPEN FLAME TO CHECK FOR LEAKS! Leak Test Points BURNER ADJUSTMENT Each burner is tested and adjusted at the factory prior to shipment; however, variations in the local gas supply may make it necessary to adjust the burners. The flames of the burners should be visually checked and compared with flame height drawing below. Flames should be blue and stable with no yellow tips, excessive noise or lifting. If any of these conditions exist, check if the air shutter or burner ports are blocked by dirt, debris, spider webs, etc. With a proper flame height, adjust the air shutter to obtain a blue flame with no yellow tipping that sits on the burner at the burner ports. The air shutter is locked in place by a set screw which must be loosened prior to lighting the burner for adjustments. To access the air shutter on the side burners, remove the grates, burner bowls, and grate support. With a screw driver, loosen the lock-screw on the face of the air shutter. Light the burner and adjust according to the directions below. 1. If the flame is yellow, turn the air shutter counter clockwise to allow more air to the burner. 2. If the flame is noisy and lifting away from the burner, turn the air shutter clockwise to reduce the amount of air to the burner. Once adjusted, turn the burner off, tighten the set screw on the air shutter, replace the grate support, burner bowls, and grates. To ensure proper installation of the side burners, slide opening in air shutters over the orifice located in the front of the unit. Air Shutters FLAME HEIGHT 1½" (3.8 cm) 3/8" (.95 cm) Orifice 12 13