Viking TVDR361 Installation Instructions - Page 13

Gas Requirements

|

View all Viking TVDR361 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 13 highlights

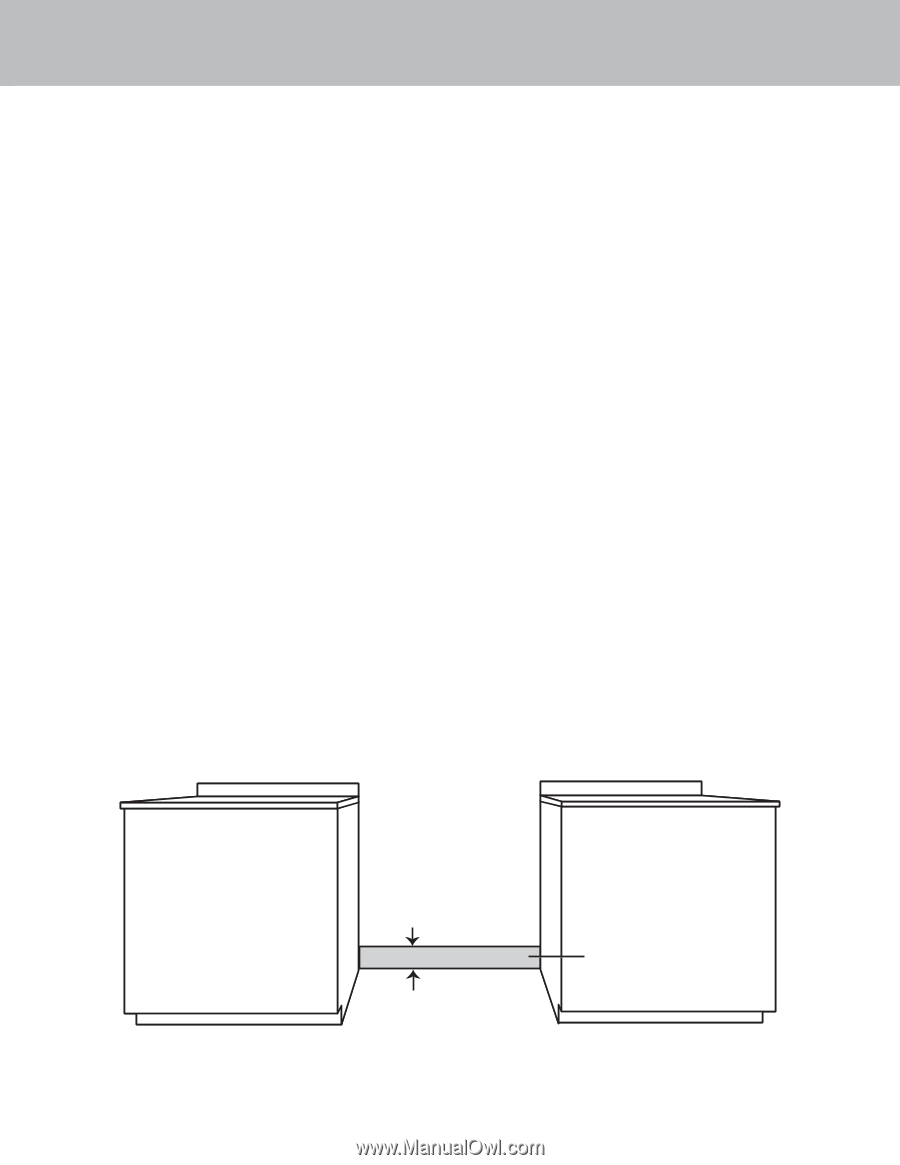

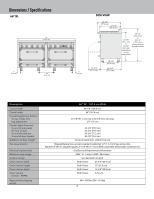

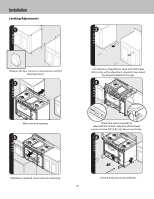

Gas Requirements Gas Connection The gas supply (service) line must be the same size or greater than the inlet line of the appliance. This range uses a 1/2" (1.3 cm) ID NPT (Sch40) inlet. Sealant on all pipe joints must be resistive to LP gas. The range is designed specifically for natural gas or liquid propane (LP) gas. Before beginning installation verify that the model is compatible with the intended gas supply. Manual shut-off valve: This installer-supplied valve must be installed in the gas service line before the appliance in the gas stream and in a location where it can be reached quickly in the event of an emergency. Any opeing behind the range shall be sealed. In Massachusetts: A "T" handle type manual valve must be installed in the gas supply line to the appliance. Pressure Regulator: •All heavy-duty, commercial type cooking equipment must have a pressure regulator on the incoming service line for safe and efficient operation, since service pressure may fluctuate with local demand. External regulators are not required on this range since a regulator is built into each unit at the factory. Under no condition should this built-in regulator be bypassed. •Manifold pressure should be checked with a manometer, natural gas requires 5.0"W.C.P. and LP gas requires 10.0"W.C.P. Incoming line pressure upstream from the regulator must be 1" W.C.P. higher than the manifold pressure in order to check the regulator. The regulator used on this range can withstand a maximum input pressure of 1/2" PSI (14.0" W.C.P.). If the line pressure is in excess of that amount, a step down regulator will be required. •The appliance must be disconnected from the gas supply piping system during any pressure testing of that system. Flexible Connections: If the unit is to be installed with flexible couplings and/or quick-disconnect fittings, the installer must use a heavy-duty AGA design-certified flexible connector of at least 1/2" (1.3 cm) ID NPT (with suitable strain reliefs) in compliance with ANSI Z21.41 and Z21.69. In Canada: CAN 1-6, 10-88 metal connectors for gas appliances and CAN 1-6.9 M79 quick disconnect devices for use with gas fuel. In Massachusetts: This appliance must be installed with a 36" (3-foot) long flexible gas connector. 3-3/4" (9.5 cm) 13 Gas / electrical connection in this area